gas filling of ig units

advertisement

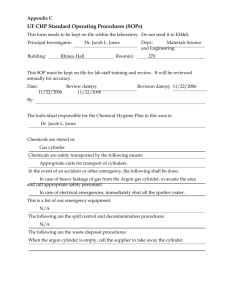

GAS FILLING OF IG UNITS RANDI ERNST CEO & Janitor FDR Design, Inc. FDR Design, Inc. Page 1 TABLE OF CONTENTS CHAPTER 1: What is a Gas-Filled Sealed Insulating Glass Unit?................................... 3 CHAPTER 2: Why Does it Work?...................................................................................... 7 Window Construction.................................................................................. 7 Synergy........................................................................................................ 8 CHAPTER 3: Sealed Units and Our Environment............................................................ Atmosphere................................................................................................. Gas Laws..................................................................................................... The Role of Breather Tubes & Capillary Tubes.................................... 10 10 11 13 CHAPTER 4: What Are the Benefits of Gas-Filled Sealed Units?..................................... 14 Energy Savings/Environment....................................................................... 14 R-Value / U-Factor / U-Value.............................................................. 14 LEED...................................................................................................... 15 What Consumers Expect.........................................................................15 Comfort........................................................................................................ 16 Preservation of Coatings & Materials.......................................................... 16 A Way to Test For Longevity........................................................................ 16 CHAPTER 5: How Do We Gas-Fill Sealed Units?............................................................. 18 3 Methods..................................................................................................... 18 Two Hole Filling ......................................................................................... 19 One Hole Filling.......................................................................................... 20 Typical One Hole Filling Speed................................................................... 21 Gas Consumption......................................................................................... 22 CHAPTER 6: Quality Assurance of Gas-Filled Sealed Units............................................. 23 Industry Standards........................................................................................ 23 Methods of Testing....................................................................................... 23 GasGlass........................................................................................... 24 Why No Studies?.......................................................................................... 25 CHAPTER 7: How Do I know What I’m Buying?............................................................. 27 CHAPTER 8: Glossary of Terms & Links.......................................................................... 28 APPENDIX: ............................................................................................................................ 33 FDR Design, Inc. Page 2 CHAPTER 1: What is a Gas-Filled Sealed Insulating Glass Unit? When the first t wo pieces of glass were sealed together it was not for energy savings. The two pieces of glass were sealed together to eliminate having to clean the two inner surfaces of glass. The thermal performance of two clear pieces of glass sealed together is the same as the traditional two pieces of glass, one being the window the other being a storm window. Sealing the layers together created a new problem; condensation of water vapor between the layers of glass. Desiccant was introduced into the sealed cavity to “super dry” the air and sealants were improved that would prevent water vapor from entering the “super dried” cavity. This presented an opportunity as we now have a closed cavity with very good seals. If the extremely small water vapor molecules could be excluded it would be easy to trap a gas other than air. Exterior Air Film R–0.17 So the question in the back of every fabricator’s mind is, “Can I build a unit that will retain gas?” Interior Air Film R–0.68 3mm Glass Pane R–0.06 If you can build a unit that will keep moisture out, you are already building a unit that will keep gas in. The moment you placed desiccant in that sealed cavity the battlefield was created. A super dry gas was now inside your sealed unit. A gas that was very different from the moist air outside the cavity that desperately wants in. The same design elements that keep moist air out of your sealed cavity will keep the gas fill in. “Can I build a unit that will retain gas?” FDR Design, Inc. Page 3 Types of Gases The noble gases, Argon, Krypton and Xenon offered the most practical solution–stable, inert, and less thermally conductive than air. Of the three argon is the most plentiful–almost one percent of the air we breathe and consequently the most economical to use. In the chart below we see a listing of the properties of the noble gases and their position in the periodic chart of elements. The Noble Gases Name Formula Molecular Weight Specific Gravity Boiling Point °F Conductivity O2N2 28.96 1.00 –317.8° to –312.4° .0150 Argon Ar 39.95 1.38 –302.6° .0100 Krypton Kr 83.8 2.89 –244.0° .0053 Xenon Xe 131.3 4.61 –162.6° .0032 Carbon Dioxide CO2 44.01 1.52 –109.4° .0092 Sulfur– Hexafluoride SF6 146.054 5.32 –82.7° — Air 2 2 HELIUM He 4.00260 10 NEON 2 8 Ne 20.179 18 ARGON Ar 2 8 8 39.948 The Periodic Table 36 KRYPTON 2 HELIUM He 4.00260 10 NEON Ne 20.179 18 ARGON Ar 39.948 36 KRYPTON Kr 54 83.80 XENON Xe 131.30 86 RADON Rn (222) Kr 54 2 8 18 8 83.80 XENON Xe 2 8 18 18 8 131.30 86 RADON Rn 2 8 18 32 18 8 (222) Argon Atom Noble metals are metals that resist corrosion by water and acid, e.g. gold, silver, platinum. Noble gases are in group 8 of the table of elements. None of the noble gases chemically combines with any element. FDR Design, Inc. Page 4 Since the “insulation” in multiple-glazed windows is the entrapped gas, increasing the gas space thickness decreases overall U-Factor (U-Value). For example multiple-glazed units with a half inch “air” space have lower U-Factors than those with quarter inch “air” spaces. However, the effect of increasing the thickness of the gas space is limited. Beyond a certain thickness, interpane convection increases carrying heat from the inner to the outer pane through gas circulation. Further increases in gas space thickness do not result in decreased U-Factor. The exact thickness at which convection becomes a dominant heat transfer mechanism depends on the height of the glass unit, the gas used, and the temperature differential between indoors and outdoors. work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Double Glazed Low-e 0.04 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.60 Center-of-Glass U-factor (BTU/h*ft 2*F) 0.55 0.50 0.45 0.40 0.35 0.30 0.25 0.20 0.000 0.200 0.400 0.600 0.800 1.000 1.200 Glass Spacing (inches) Air Argon 90% Krypton 90% These charts found in the Appendix are simulations done by WestLab under joint funding by Spectra Gases, WestLab and FDR Design. The horizontal axis or X axis shows the spacer width or air gap. The vertical axis or Y axis shows the thermal performance. If a U-Factor chart, the lower the number the more resistance to energy transfer. So for example a U-0.25 is “better” than a U-0.30. FDR Design, Inc. Page 5 Clear glass lets long wave radiation pass readily. 50% of the energy transferred out a clear glass window is due to radiation, 25% is due to conduction. The other 25% of the energy is due to convection. Until the door could be shut on the large radiant transfer, gas filling would not be viable. What finally made gas filling worthwhile was the introduction of low cost Low-Emittance coated glass and plastic film. Exterior Pane (cold) Long Wave Infrared Radiant Heat Transfer Convective Heat Transfer Commonly called “low-e” this revolutionary coating could effectively block the radiant heat transfer. Now with radiation transfer under control, argon could be used to reduce the conductive loss. The figure below depicts a hermetically sealed unit with one low-e coated glass pane. Interior Pane (warm) Conductive Heat Transfer Exterior Pane (cold) Long Wave Infrared Radiant Heat Transfer Low–Emissivity Coating Clear air — U-0.50 Clear argon — U-0.45 Low-e air— U-0.30 Low-e argon — U-0.25 Convective Heat Transfer Interior Pane (warm) Conductive Heat Transfer Glass manufacturers could produce units made with low-e glass and an argon fill, a product with twice the performance of clear sealed units, using the same basic manufacturing process they were already using. FDR Design, Inc. Page 6 CHAPTER 2: Why Does it Work? Window Construction Simply put, Argon, Krypton and Xenon are less conductive than air. Krypton and xenon will yield roughly the same performance as argon but in two-thirds to one-half the cavity width. Krypton gas allows a narrow unit to be manufactured that has high performance. Krypton is used most often with three layers, the center layer being a plastic film as shown in the figure below. Indium Oxide Film Indium Oxide Silver Silver Indium Oxide Indium Oxide Film Glass Panes Krypton Fill Xenon, due to its rarity and subsequent high cost, is seldom used. Because gas filling is effective, inexpensive and relatively easy to do, it has become assumed that a low-e product will include a gas fill. FDR Design, Inc. Page 7 1+1=5 Synergy The interaction of two or more agents or forces so that their combined effect is greater than the sum of their individual effects. Conduction takes place when a temperature gradient exists in a solid (or stationary fluid) medium. Energy is transferred from the more energetic to the less energetic molecules when neighboring molecules collide. Conductive heat flow occurs in the direction of decreasing temperature because higher temperatures are associated with higher molecular energy. The equation used to express heat transfer by conduction is known as Fourier’s Law. q = k A dT / s (1) where q = heat transferred per unit time A = heat transfer area k = thermal conductivity of the material dT = Temperature difference across the material s = material thickness 45° 7° 57° 4° ∆T = 38° ∆T = 53° To have flow we need difference, high pressure to low pressure, up hill to down hill, or in our case hotter to colder. FDR Design, Inc. Page 8 There are multiple consequences of putting low-e on one of the glass surfaces. The obvious one is that radiant heat is reflected back into the room. A not so obvious one is that the outer glass surface temperature lowers and the inner glass surface temperature rises. Greater temperature difference means more flow of energy by way of conductive heat transfer. 15⁄ " or 23mm 16 Exterior Pane (cold) Long Wave Infrared Radiant Heat Transfer Convective Heat Transfer Interior Pane (warm) Conductive Heat Transfer 45° 7° ∆T = 38° 15⁄ " or 23mm 16 Exterior Pane (cold) Low–Emissivity Coating Long Wave Infrared Radiant Heat Transfer Convective Heat Transfer Interior Pane (warm) Conductive Heat Transfer 57° 4° ∆T = 53° This then explains the synergistic relationship between gas fill and low-e and why the benefit of a gas fill is greater on a unit with low-e coatings than with clear glass. Low-e creates a greater temperature difference giving the argon more work to do. FDR Design, Inc. Page 9 CHAPTER 3: Sealed Units and Our Environment Atmosphere Trick Question – Where is the largest ocean on earth located? It’s the air all around us. We are the bottom dwellers in an ocean of air. Air (a gas) is just like water (a liquid), in that both are fluid. Both make oceans, have currents and waves and help man move about the planet. Boats float in and on water. Balloons float on air. Airplanes, like birds, fly with air holding up their wings. Water fills in all the low points on the planet up to sea level. Air, wispy thin, a few hundred miles above our head gets thicker and thicker until it reaches land or water. We like to say a bottle or box is empty. In fact, it is not ............ It is full of air. Sometime around 1590 Galileo Galilei (1564 – 1642) is said to have climbed to the top of the Leaning Tower of Pisa and dropped some balls to the ground. Doing so proved to himself that air had friction so it must be something. In additional experiments he concluded that air weighed about 1/400 of water. FDR Design, Inc. Page 10 It is amazing how many people think there is a vacuum between the two layers of glass on a sealed unit instead of whatever air was in the plant that day. “If I have seen further it is by standing on ye shoulders of giants.” Isaac Newton (1643 - 1727) Because there is something in the sealed unit (a gas that expands and contracts readily), the glass will always be moving, swelling and contracting. This is made worse if the unit’s location or elevation is changed. Gas Laws Gas Laws - The expansion of air (gas) due to pressure or temperature changes is predictable. The General Gas Law is the combination of Charles’ Law and Boyle’s Law. P1 V1 ---------T1 P2 V2 = ---------T2 Charles’ Law states: V1 ------- = T1 V2 ------T2 Where: V = Volume and T = absolute temperature ˚C+273 The volume of gas is proportional to the temperature. The higher the temperature, the greater the volume, if pressure is constant. If we know the starting temperature, the average temperature of the gas in the IG when it was sealed and the temperature at the installation site, we can calculate the effect temperature has on the volume of gas trapped in the IG. Boyle’s Law states: P1 V1 = P2 V2 The volume of fixed mass of gas at constant temperature is inversely proportional to the pressure. If pressure goes up, volume goes down. The value of pressure times volume becomes a constant. V2 = P1 V1 ---------P2 So, if we know starting elevation, P1 (pressure one) and we know destination elevation, P2 (pressure 2), and we know how much air or gas is in the IG, V1 (the initial volume of gas), we can calculate V2, the volume of air or gas at the destination. FDR Design, Inc. Page 11 Rule of Thumb You need to seal a unit at 52°F @ 1000 feet to have the pressure neutral at 70°F @ sea level. Conversely, you need to seal a unit at 88°F @ sea level to have neutral pressure at 70°F @ 1000 feet. Unit size 20” x 24” x 0.250” Cavity Volume = 2.36 liters 1000’ = 14.2 psi 0’ - 14.7 psi 52°F to 70°F will expand 2.36 liters of gas to 2.44 liters (0.08 liters) 1000’ to 0’ will reduce 2.36 liters of gas to 2.28 liters (0.08 liters) The rule of thumb would then be: 18°F for 1000 feet of elevation or 1.8°F for 100 feet. 1°C = 1.8°F so 1°C for 100 feet elevation change. Keep in mind that barometric pressure also plays a role. A one inch barometric pressure change when a front comes through is equal to 1000 feet of elevation change. Pressure needs to be equal. High to low = concave Low to high = convex FDR Design, Inc. Page 12 The Role of Breather Tubes & Capillary Tubes A breather tube is a large diameter tube inserted in the insulating glass unit to allow the pressure in the insulating glass to be equalized with pressure surrounding the insulating glass unit at installation. Once at its installation elevation, the tube is pinched and sealed (soldered or some other form of barrier). In some cases breather tubes are left open during shipping to allow the rapid equalization of the insulating glass unit as it is transported. If used with gas filling, the breather tube must be sealed before the insulating glass unit is filled with gas, opened at the installation elevation and then resealed after the unit has equalized. If the unit is going to a lower elevation, this breaching of the insulating glass cavity will dilute the gas concentration. If going to a a higher elevation, the concentration is unaffected as the excess pressure is expelled from the insulating glass. Capillary tubes normally are not used with gas filling. The purpose of a capillary tube is a controlled, small leak in the sealant system. As a result of this small leak, the gas fill will migrate out and exchange itself with air. The myth that the capillary tube is small enough in diameter to keep gas in is not true. It is small enough to slow down the exchange from seconds to perhaps hours but not small enough to trap the gas molecules from escaping the interior of the insulating glass unit. Nor is it small enough to significantly reduce the flow rate through the tube due to pressure differential. With a difference of one inch of mercury the flow rate will be 20 c.c. per minute. A manufacturer in Colombia builds and gas fills units with open capillary tubes at sea level and then transports them to Bogota at 10,000 feet. It takes several days to truck them up the mountain and once they are at the higher elevation the tubes are sealed.This manufacturer is not installing a capillary tube for use in the traditional sense where it is permanently left open. It is actually a small diameter breather tube. The purpose of the tube being to vent excess pressure. Once at the installation elevation the capillary tubes are permanently sealed closed. FDR Design, Inc. Page 13 CHAPTER 4: What Are The Benefits of Gas-Filled Sealed Units? Why should we gas fill sealed units? In the early days it was the standard question we would hear at association meetings or trade shows. All of the high performance insulating glass components (low-e, gas fills, sealants and spacers) were viewed with considerable skepticism when they were introduced 30 some years ago. Energy Savings/Environment Comfort Preser vation of Coatings & Materials A Way To Test For Longevity Energy Savings/Environment The simple reason is because it works and is cost effective. For a manufactured cost of just a few pennies per unit we can improve the center of glass performance by 10 to 15 percent. R-Value / U-Factor / U-Value Reciprocal [1/x] a U-Factor of 0.25 would equal an R-Value of 4.0 a U-Factor of 0.35 would equal an R-Value of 2.9 At present, a “typical” high performance window has an overall U-Factor around 0.35. An overall U-Factor of 0.35 is achieved when all three components; frame, edge of glass and center of glass, are all roughly the same U-Factor. The edge of present technology yields an overall NFRC U-Factor of around 0.25. To go beyond is going to require some effort as it will require improving all three components. It is important to remember when looking at the charts that we are only looking at center of glass performance or roughly 1/3 of the overall performance of an installed window. To obtain an overall performance U-Factor we also have to know the U-Factors of the edge of glass and the window installed frame. FDR Design, Inc. Page 14 LEED, Follow, or Get Out of the Way! LEED: Leadership in Energy and Environmental Design LEED is a third party certification program and the nationally accepted benchmark for the design, construction and operation of high performance green buildings. LEED™ has four performance ratings: 26 to 32 points: Certified 33 to 38 points: Silver 39 to 51 points: Gold 52 or more: Platinum “Buyers expect a lot of big windows... today’s engineered glass makes floor-to-ceiling windows more practical and desireable.” In some projects gas filling the units can add one full LEED point and save 3% of the energy used by the building. “The National Energy Technology Laboratory, on behalf of the Office of Energy Efficiency and Renewable Energy’s Bulding Technologies Program, intends to issue a Funding Opportunity Announcement (FOA) to select and fund approximately t wo teams to develop, manufacture, and commercialize cost effective, highly insulating windows with an NFRC U-Factor rating of 0.20 BTU/hr-Ft2-°F or lower. This FOA is expected to be issued on or about April 21, 2008.” What Consumers Expect - Everyone Knows the Technology is There Minneapolis StarTribune Feb 15, 2008 “Buyers expect a lot of big windows,” said Scott Parkin, principal with Hoffman Parkin Urban Realty and sales manager at Cobalt, the Minneapolis condo building where Hengel recently bought her home. “Everyone knows the technology is there; 50 years ago you couldn’t do it [glass-walled units], you’d lose so much heat,” Parkin said. But today’s engineered glass, with double panes and a layer of insulating air or gases, makes floor-toceiling windows more practical and desirable. FDR Design, Inc. Page 15 Comfort The initial selling point of these high performance windows was energy savings, but people quickly discovered they were more “comfortable” to be near due to the warmer surface temperature of the glass. Surface Temperature of Glass Outside Temperature 0° F Inside Temperature 70° F F° 80° 70° 60° 50° 40° 30° 20° 10° 0° -10° 54° 45° 57° 47° 17° Single–Clear Dual–Clear–Air Dual–Clear-Argon Dual–Low E–Air Dual–Low E–Argon In the wintertime we are raising the inside surface temperature of the glass. That warm surface temperature is critical to condensation resistance and comfort. The closer the surface temperature is to room temperature the more comfortable the glass is to be near. Preservation of Coatings & Materials A more subtle reason to gas fill is to help preserve the low-e coatings and other materials in the sealed unit. Replacing moist factory air with dry, inert argon helps stabilize the environment in which all these components are entombed for the next 30 or so years. This is not a requirement as all the component fabricators and glass coaters have gone to great efforts to produce products that will not oxidize or age, but it can’t hurt. A Way To Test For Longevity An even more subtle reason, one that we are just seeing emerge, is that gas filling a unit will raise the overall quality and care that goes into making the unit. A PRETTY BOLD STATEMENT Gas filling a unit will raise the overall quality and care that goes into making the unit. FDR Design, Inc. Page 16 Here is what I mean. Now that we have the technology to check for argon gas retention in units installed in the field, fabricators are under increased scrutiny. Good fabricators don’t mind, in fact they welcome the comparison of their well-made units to some of the units made by distant cousins who, perhaps, have not been producing a unit to the same demanding standards. When there is no finish line, no way to measure, everyone looks the same, no one wins. The premise to this idea is that whatever will keep the gas in will keep other stuff out, specifically moisture. At this point in time the industry considers a sealed unit to have failed or died when the interior surfaces are fogged with moisture. Once this fogging occurs the low-e will also fail, thermal performance is compromised. More importantly the fogging is unsightly and very frustrating for the property owner. So if we can keep the gas in the unit we know it is healthy and will continue to live a long life. If on the other hand we can’t keep the gas in, we know we have an unhealthy unit and it is going to have a shorter service life. When a fabricator makes the decision to gas fill his units he makes additional efforts to be certain the gas remains in the unit. Everything from component and material selection to training, machinery and craftsmanship on his production line. These efforts are like having good genes, of having no history of illness in the family. Good genetics are no guarantee that you are going to stay healthy and a number of factors can still make you sick, but you are starting out on the positive side of the ledger. FDR Design, Inc. Page 17 CHAPTER 5: How Do We Gas Fill Sealed Units? There are three general methods for gas filling insulating glass. 1. Assemble the unit in a gas filled environment, requiring a sealed gas filled assembly press. 2 Assembly Press 10 10 Spacer 3 Glass Panes Step 1: The two panes are moved into place and the press is sealed Step 2: Argon is flooded into the bottom of the chamber as the air exhausts out the top Step 3: The panes are pressed together, sealing the argon inside 2 1 2. Place the assembled unit in a chamber, pump all the air out of the chamber (and the units) and then replace the air with gas. 2 10 1 10 30 1 2 Step 1: The air in the chamber and in the window is pumped out, creating a vacuum Step 2: Argon is flooded into the chamber and consequently into the window Chamber Filling FDR Design, Inc. Page 18 3. Insert one or more lances into the insulating glass cavity via access hole(s) and exchange the air trapped in the cavity with gas. 1 10 10 Step 1: Argon is flooded into the bottom as the air exhausts out the top 1 Lance Filling Two Hole Filling Method Because we cannot see air and argon, it can be difficult to comprehend how gas filling of insulating glass is done. The traditional two hole filling concept is really quite simple. Argon is about forty percent heavier than air. For a short period of time air will actually float on top of argon. FDR Design, Inc. Page 19 By carefully introducing argon at the bottom of an insulating glass unit, it is possible to float the air up and out the top. The key ingredient being this careful introduction of the argon. One Hole Filling Method One-hole filling methods have now been developed. If argon is turbulently introduced this lamination will not occur. The window must then be filled by stirring in large amounts of argon and eventually diluting the mixture of air and argon to mostly argon. air mix of air and gas fill gas mix of air and gas mix of air and gas mix of air and gas fill gas The goal of one hole filling is to stir the gas into the cavity as turbulently as possible. This violent introduction of gas is accompanied by a rapid evacuation of the air needing to be removed, assisted by the vacuum pump. The turbulent exchange of incoming gas and outgoing air is continued until the conductivity sensor has determined the evacuated air / gas mixture has reached the preset shut off point. FDR Design, Inc. Page 20 Because one hole filling was designed with the purpose of having only one hole in the spacer, relative efficiency was not a concern. The total volume of gas in the IG will be replaced 3 to 4 times to obtain >90% fill, as compared with 2 to 3 times for the two hole filling method. For this reason, it is not advised to use the one hole filling method with more expensive and exotic gases like krypton or xenon. Argon, however, is relatively inexpensive, and while the spent gas is still an expense, less labor is required as only one hole in the spacer has to be sealed. We use the term “Turns” to define how many times the volume of gas in the IG has been turned over, or replaced. Once the window is filled and sealed a minute amount of gas will gradually seep out of the unit, not only from the top, but from all sides. The gas, as it dilutes over time, will not be of different concentrations moving from the top to the bottom of the window, but rather completely mixed together. If the window is ninety percent argon and ten percent air, this same concentration is present everywhere in the cavity. Typical One Hole Filling Speed Flow rate: 15 - 28 liters per minute (argon), per line. Normally the gas filling machine is set to yield 95%(±2) fill rates for two hole filling and 92% (±2) fill rates for one hole filling. The machine can also be adjusted for various filling percentages by adjusting the calibration voltage on the gas sensor amplifier board. Fill rates are largely dependent on the operator’s skill and unit construction. FDR DESIGN, INC. 303 12th Ave South! Buffalo, MN 55313! (763) 682-6096 Fax (763) 682-6197 RSGh Calibration! 100% Argon Gas Sensor Argon Setting Step 2 Created: 3/24/00 rle Last Modified: 7/21/03 Sheet 4 of 4 Drawing Number: Scale: cg 11541-A na Gas Filler argon or gain calibration Press and hold cycle start button! (or flip Sensor O-ride to up position) Step 1 Lance in test can Step 3 filling lance sniffler 5.00 Output com 24 + V ... 20 Gain Black Zero Tab Is Test Pt. Sensor Common Air = .013 vdc! Argon= 5.00 vdc Sensor 23 ma + Red With lance in the test can! adjust gain to 5.00 volts dc FDR Design, Inc. Page 21 Gas Consumption The amount of gas used is dependent on the IG unit size and configuration. To determine the length of time your argon tank will last multiply the liters used per window by the number of units normally filled per shift. EXAMPLE: IG unit is 10 liters in size Gas loss is 100% in each IG (2 turns) Filled IG unit will require 20 liters of argon Two Hole! 110% to 200% ! of cavity volume When 2 hole laminar filling, the typical amount of gas used is 110% to 200% of cavity volume (approximately 2 “turns” of the cavity volume). The condition of the lance and the Sniffler™ can greatly influence the amount of gas lost in the filling process. One Hole! 300% to 400% ! of cavity volume When 1 hole filling, the typical amount of gas used is 300% 400% of cavity volume (approximately 3 to 4 “turns” of the cavity volume). A typical argon tank holds 10,000 liters and will fill around 400 units. FDR Design, Inc. Page 22 CHAPTER 6: Quality Assurance of Gas Filled Sealed Units Industry Standards The industry has set voluntary production standards and test procedures to assure properly fabricated products. The conclusion reached by those researching standards is gas is only lost if and when the edge seal around the glass perimeter fails. When the seal fails, the glass will show visible fogging due to the introduction of water vapor. Consequently, unless the unit has visibly failed, the consumer should be assured that most of the argon has been retained. Industry standards call for a minimum 90% initial gas fill prior to accelerated testing. After accelerated testing units must have an 80% fill rate. A low-e unit with just an “air” fill is still a very good unit. Gas filling typically adds 10 to 15 percent to the performance of the window. For example if the U-Factor of an air filled unit was U-0.30, a gas-filled unit might have a center of glass U-Factor of U-0.25. As the gas escapes the U-Factor will increase linearly from U-0.25 to U-0.30. Methods of Testing Quality assurance can be accomplished by drawing samples from the insulating glass cavity and testing them for residual oxygen with an oxygen analyzer or testing for the specific gases with a gas chromatograph. Video thermography offers a method of analyzing thermal performance of the whole package—gas, glass and spacer. http://www.greengarnetconsulting.com/ Raymond Dums - Thermographer RayDums@GreenGarnetConsulting.Com Phone 713.436.2021 Cell 608.385.4907 Green Garnet Consulting 13005 Imperial Shore Drive Pearland, Texas 77584 In the past, we did not have an easy way to determine the gas fill of a sealed unit. Testing meant removing the unit from service and bringing it to a lab. The most common test was destructive and required drawing a sample of gas from the sealed cavity and analyzing it. FDR Design, Inc. Page 23 That all changed as we entered the 21st century with the introduction of a device developed by Sparklike in Finland called the GasGlass. The GasGlass was the first device to cross the finish line. Several other technologies were being actively pursued. Sparklike’s GasGlass got there first and, more importantly, GasGlass technology works so the other technologies will most likely remain on the shelf. The design of the Gasglass Handheld is light, battery driven and very easy to use. By flushing the analyzer against an insulating glass window and pressing a button, the operator will get an instant result on the gas concentration inside the insulating glass window. All the measurements can be logged and at any stage downloaded to a PC for further handling. Testing installed units with the GasGlass is like going to the doctor for a yearly physical. By looking at today’s test results and comparing them to past results we can predict what will happen in the future. FDR Design, Inc. Page 24 Why No Studies? We set as a design target for a gas loss rate of less than 1 percent per year, but really we had no idea what we would actually observe as the years rolled by. The good news is word is now filtering back to us from various sources that actual gas loss is significantly less than we designed for. This was not a total surprise. A number of people had challenged the test methods and felt that real world results would be much better than the accelerated aging gas loss tests indicated. I anticipate studies and papers to be written over the next few years. An example is the study we are doing on the FDR building here in Buffalo, Minnesota, with the 40 units installed in our building in 1991. As of May 2007 they had an average argon fill level of 89%. This is a strong indication that the units are healthy, are working just fine, and will have a long life ahead of them. Our units were produced by SNE. At that time their minimum initial fill requirements were 88%, the normal range of initial argon fills was 90 to 95%. 2007 40 unit average 89% 40 units 1991 FDR Design, Inc. Page 25 How long will the FDR units last? We don’t know yet as we have not had this testing technology long enough to make accurate predictions, nor do we have correlated data to accelerated aging in test cells. I am confident that with GasGlass technology information is going to be collected and published. Progressive certification programs have already integrated testing initial gas fill in their certification process. American Society for Testing and Materials (ASTM), has a standard test method in development for use of the GasGlass device. FDR Design, Inc. Page 26 CHAPTER 7: How Do I Know What I’m Buying? As someone who specifies products or as a buyer, how do I know I am getting a sealed unit that is durable and will last, giving peak performance over its expected life? I want a healthy unit, not one that will get sick on me. So how do I know what I am buying? At this point about all you can do is look closely at the fabricator’s track record and his warranty. Then look for a stringent certification or quality control program. The new European program is a prime example of a strong certification program. Unlike North American programs, the European programs are being mandated by law in order to obtain the CE mark. In North America a different approach has been chosen where ultimately the consumer decides and fabricators use voluntary certification methods. Looking for a certification program that is demanding and requires documented quality control methods and records is your best assurance of purchasing a unit that will live a long productive life, irrespective of being gas or air filled. While having a high initial gas fill is important for performance, arguably more important is having some assurances that the unit is going to stay sealed and have reasonable durability once installed. As new products enter our market we know that not all products will be produced domestically. We live in an ever-shrinking world so it will be even more prudent to assure that you have purchased a certified unit, or a unit built to strong certification procedures. FDR Design, Inc. Page 27 CHAPTER 8: Glossary of Terms & Links Argon Chemical formula: Ar. Colorless, odorless, nonflammable, non-reactive, inert gas which is compressed to high pressures. Acts as a simple asphyxiant by displacing air. Major hazards: High pressure and suffocation. Most often used for gas filling due to low cost and ready availability. Argon performs well as an insulator and is chemically inert to UV radiation, heat, glass coatings, and spacers. Argon has a low diffusion rate, a significant property since it is imperative the gas not diffuse through sealing materials. (A 75 to 80 percent gas retention rate over the life of the IG is minimal for satisfactory performance.) ASTM www.astm.org ASTM International, originally known as the American Society for Testing and Materials, is one of the largest voluntary standards development organizations in the world-a trusted source for technical standards for materials, products, systems, and services. Boyle’s Law For a fixed amount of gas kept at a fixed temperature, P and V are inversely proportional (while one increases, the other decreases). Building Technologies Program www.eere.energy.gov/buildings Run by the U.S. Department of Energy, this program works in partnership with states, industry, and manufacturers to improve the energy efficiency of our nation’s buildings. Through innovative new technologies and systems-engineered building practices they are transforming how we design, build, and operate the approximately 15 million new buildings projected to be constructed by 2015. Carbon Dioxide Chemical formula: CO2. Colorless, odorless, nonflammable, liquefied high pressure gas which is slightly acidic and is shipped at its vapor pressure of 820 psi. Major hazards: High pressure and suffocation. CE Mark A mandatory European marking for certain product groups to indicate conformity with the essential health and safety requirements set out in European Directives. cfh Abbreviation for “cubic feet per hour.” Charles’Law At constant pressure, the volume of a given mass of an ideal gas increases or decreases by the same factor as its temperature increases or decreases. Chromatograph Introduced by James and Martin in 1952. This instrument provides a time separation of components in a mixture. The basic operating principle of a gas chromatograph involves volatilization of the sample in a heated inlet port (injector), separation of the components of the mixture in a specially prepared column, and detection of each component by a detector. FDR Design, Inc. Page 28 Conduction The transfer of heat between two parts of a stationary system, caused by a temperature difference between the parts. Convection - see Interpane Convection Desiccant A substance that promotes drying. °F Degrees Fahrenheit. Fourier’s Law States that the time rate of heat transfer through a material is proportional to the negative gradient in the temperature and to the area at right angles, to that gradient, through which the heat is flowing. We can state this law in two equivalent forms: the integral form, in which we look at the amount of energy flowing into or out of a body as a whole, and the differential form, in which we look at the flows or fluxes of energy locally. Funding Opportunity Notice (FOA) A notice in Grants.gov of a federal grant funding opportunity. Grants.gov lets organizations apply for grants for over 1,000 grant programs from 26 federal agencies. General Gas Law The combination of Charles’ Law & Boyle’s Law. Hz Abbreviation for “cycles per second.” IGU Abbreviation for “insulating glass unit.” Also IG. Interpane Convection The movement of currents within two panes of glass. kPa A measure of pressure meaning “kilo-Pascals.” Krypton Chemical formula: Kr. Colorless, odorless, nonflammable, non-reactive, inert gas which is compressed to high pressures. It acts as a simple asphyxiant by displacing air. Major hazards: High pressure and suffocation. Lamination A layered structure. FDR Design, Inc. Page 29 Leadership in Energy and Environmental Design (LEED) LEED is a third party certification program and the nationally accepted benchmark for the design, construction and operation of high performance green buildings. LEED gives building owners and operators the tools they need to have an immediate and measurable impact on their building’s performance. LEED promotes a whole-building approach to sustainability by recognizing performance in five key areas of human and environmental health: sustainable site development, water savings, energy efficiency, materials selection and indoor environmental quality. Low-E Microscopically thin, virtually invisible, metal or metallic oxide layers deposited on a window or skylight glazing surface primarily to reduce the U-factor by suppressing radiative heat flow. lpm Abbreviation for “liters per minute.” mm Abbreviation meaning “millimeters.” mV Abbreviation meaning “millivolts.” National Energy Technology Laboratory (NETL) www.netl.doe.gov Part of DOE’s national laboratory system and owned and operated by the U.S. Department of Energy (DOE). NETL supports DOE’s mission to advance the national, economic, and energy security of the United States. National Fenestration Rating Council (NFRC) A 501 (c) 3, non-profit organization that provides performance ratings on windows, doors, and skylights. The NFRC was started in 1989 to prevent potential widespread confusion, federal intervention, and possibly costly litigation. Noble Gases The noble gases are the non-metal, chemically inert elements in group 18 of the periodic table. Chemically, the noble gases are very stable due to having the maximum number of valence electrons their outer shell can hold. Noble gases rarely react with other elements since they are already stable. Under normal conditions they occur as odorless, colorless, monatomic gases. Each of them has its melting and boiling point close together so that only a small temperature range exists for each noble gas in which it is a liquid. Noble gases have numerous important applications in lighting, welding and space technology. Office of Energy Efficiency (OEE) http://oee.nrcan.gc.ca/english A part of Natural Resources Canada. Provides advice and financial assistance - including grants - to individuals and organizations to reduce energy use. OSHA Occupational Safety and Health Act. FDR Design, Inc. Page 30 PIB Abbreviation for polyisobutylene. psi Abbreviation for “pounds per square inch.” R-Value A term predominantly used in the building industry to describe the insulation properties of certain building insulation materials. Its use is limited to situations where thermal insulation is achieved by retarding the flow of heat through the material itself rather than reflecting radiant heat away. The higher the R-value the greater the insulation. The insulating value is indicated by the R-value which is the inverse of the U-Factor (U-Factor). RSG Abbreviation for “Rapid Single Gas.” Radiation Energy in the form of waves or moving subatomic particles. SU Abbreviation for “sealed unit.” Sniffler™ A tool designed and manufactured by FDR Design, Inc. to be used with their gas filling machines. Sparklike www.sparklike.com A company that has been involved in the IG industry since its foundation in 2000 and has launched the revolutionary Gasglass device. Sulfur Hexafluoride Chemical formula: SF6. Colorless, odorless, nonflammable, liquefied high pressure gas which is shipped at its vapor pressure of 310 psi. Major hazards: High pressure and suffocation. Exposure limit of 1000 ppm. SF6 improves an IGU’s sound deadening characteristics in specific frequencies; SF6 accounts for a 2 to 3 decibels increase in sound reduction. Synergy The interaction of two or more agents or forces so that their combined effect is greater than the sum of their individual effects. U-Factor (U-Value) The rate of heat loss of a window assembly. The insulating value is indicated by the R-value which is the inverse of the U-Factor. The lower the U-Factor the greater a window’s resistance to heat flow and the better its insulating value. FDR Design, Inc. Page 31 U.S. Department of Energy (DOE) www.doe.gov Ensures energy security, maintains the safety, security and reliability of the nuclear weapons stockpile, cleans up the environment from the legacy of the Cold War, and develops innovations in science and technology. U.S. Green Building Council (USGBC) www.usgbc.org A 501(c)(3) non profit organization that certifies sustainable businesses, homes, hospitals, schools, and neighborhoods. vac Abbreviation for “volts alternating current.” vdc Abbreviation for “volts direct current.” Also DC for “direct current.” Video Thermography Detects radiation in the infrared range of the electromagnetic spectrum and produces images of that radiation. Xenon Chemical Formula: Xe. A colorless, heavy, odorless nonflammable, non-reactive, inert gas which is compressed to high pressures. It acts as a simple asphyxiant by displacing air. Major hazards: High pressure and suffocation. FDR Design, Inc. sells machines for the production and testing of gas filled, sealed insulating glass. We manufacture our own lines of argon and krypton gas-filling equipment as well as in line testers. FDR Design also distributes Sparklike Ltd’s GasGlass device in North America. FDR Design, Inc. Randi Ernst CEO & Janitor World Leaders In Gas Filling Technology Barbara Ernst VP of Happiness Jill Furneisen Animal Control Dan Haglin Master of Disaster Kurt Wannebo Necessary Evil Shannon Weege Keeper of the Magic Allan Wiskow Master of Madness www.fdrdesign.com 303 12th Avenue South • Buffalo, MN 55313• 763-682-6096 FDR Design, Inc. Page 32 Appendix APPENDIX A: Sample Test APPENDIX B: Simulation Charts APPENDIX C: FDR Design, Inc. Page 33 IG Gas Filling Approval Test Instructor: Randi Ernst Name: Clock #:___________________________ Date: Read each question carefully, then print the letter of the correct answer on the line next to the question. 1. We want to inert gas fill our IG units because we want to: a. control visual color. b. improve insulating value. c. make the IG unit lighter in weight. 2. The inert gases we want to use are: a. argon and xenon. b. argon and neon. c. argon and krypton. 3. The use of an inert gas in an IG unit minimizes heat loss by: a. radiation and reflection. b. convection and conduction. c. color and shading. 4. When we say “inert gas fill”, “inert” refers to: a. not colored. b. not available. c. not reactive. 5. When compared to air, argon and krypton are: a. lighter in weight. b. heavier in weight. c. about equal in weight. 6. Air is mainly composed of: a. nitrogen and oxygen b. oxygen and argon c. argon and krypton Multiple choice, page 1 7. The U-value and R- value refer to: a. thermal performance. b. weight classification. c. transportation restrictions. 8. Low-E coatings on glass are special coatings which: a. mainly increase the weight of the glass. b. increase the durability of the glass. c. reflect heat or infra-red light. 9. The most important concern when making an IG unit is: a. overall quality of the unit. b. cutting the glass properly. c. filling with argon. 10. The filling method we use to inert gas fill our IG units: a. chamber filling. b. flood filling. c. lance filling. 11. What are the reasons we are mainly using argon to fill our IG units: a. it is least expensive and readily available. b. it is colored and has a strong odor. c. it is reactive and chemically inert. 12. Lance filling: a. requires one or two holes in the spacer. b. requires one or two holes in the glass. c. both a and b. 13. “Lance” refers to: a. the name of the guy who invented the filling method. b. the probe used to fill the inert gas. c. the probe used to detect moisture. 14. Two Hole Filling of IG units with inert gas requires: a. a large chamber. b. a higher vacuum. c. proper placement of sniffler and filling lance. Multiple choice, page 2 15. To measure fill percentage, the gas filling equipment will measure: a. the change in IG unit weight. b. the change in the thermal conductivity of the exhaust stream. c. the overall time it takes to fill the unit. 16. To confirm fill percentage, the ILT equipment will measure: a. the change in IG color and weight. b. the percent oxygen and thermal conductivity. c. the percent oxygen and time to fill. 17. We always Two Hole fill units with the filling lance located: a. at the top vertical side of the unit. b. on the bottom vertical side of the unit. c. neither a or b. 18. The sniffler is: a. an operator with a cold. b. the probe used to determine fill in Heat Mirror and I-8 filling. c. the probe used to insert the rivet. 19. Plugging the fill and sniffler holes means: a. sealing the fill hole with the appropriate method. b. placing your finger on the fill holes. c. leaving the holes open so the inert gas can escape. 20. Gas retention is important for: a. minimizing water condensation in the IG unit. b. maintaining the tint durability on the IG unit. c. maintaining the insulating value in the IG unit. 21. Sealing the “fill” holes with a rivet or screw is important because: a. it keeps the glass from cracking. b. it provides a clean appearance to the IG unit. c. it restores the integrity of spacer and retains the gas fill. 22. To seal the Low-E IG unit fill hole, one can use: a. a silicone plug. b. a PIB wrapped rivet. c. both a and b. Multiple choice, page 3 23. Once the fill hole has been sealed: a. there is a need to apply a secondary seal. b. no need to do anything. c. with your finger, feel the seal to see if any inert gas is escaping. 24. Dual seal refers to: a. an IG unit constructed with a primary and secondary seal. b. the use of duct tape on the edge of the IG unit. c. the use of a two part sealant to seal the edge of the IG unit. 25. When filling with an inert gas, we want: a. at least a 50% fill. b. at least a 90% fill. c. at least a 99.99% fill. 26. The gas retention capability of an IG unit: a. depends on the overall manufacturing quality of the unit. b. depends solely on the gas used. c. is a combination of handling and percent fill. 27. The added weight obtained by inert gas filling the IG unit is: a. 2 to 4 lb. b. less then an ounce. c. 6 to 8 lb. 28. The main path for gas loss in a high quality filled IG unit is: a. through the sealant. b. through the glass. c. through the spacer. 29. When Two Hole filling, which gas holes should be sealed first: a. Bottom. b. Top. c. Why bother. 30. The term calibrate means: a. to measure against the standard. b. to set flow rates. c. to set the speed of the machine. 31. We will know when an IG unit has achieved an adequate fill when: a. the sensor “senses” adequate fill. b. the glass “bulges” out. c. unit appears full. Multiple choice, page 4 32. The Low-E gas fill method used will be: a. filling from the top of the IG. b. diagonal fill through the corner key. c. horizontal fill through the spacer leg. 33. We will gas fill Low-E through: a. One gas hole. b. Two gas holes. c. Three gas holes. Read each essay question carefully, then answer each as completely as possible in the spacer provided. Use the back of this page if necessary. 1. Why do you want to become an approved gas fill operator? 2. Why is overall IG quality important to our company? Multiple choice, page 5 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Double Glazed Low-e 0.04 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.60 Center-of-Glass U-factor (BTU/h*ft2*F) 0.55 0.50 0.45 0.40 0.35 0.30 0.25 0.20 0.000 0.200 0.400 0.600 0.800 Glass Spacing (inches) Air Argon 90% Krypton 90% 1.000 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Double Glazed Low-e 0.04 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.60 Center-of-Glass U-factor (BTU/h*ft*F) 0.55 0.50 0.45 0.40 0.35 0.30 0.25 0.20 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 60% Argon 70% Argon 80% Argon 90% Krypton 90% 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Double Glazed Low-e 0.04 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.60 Center-of-Glass U-factor (BTU/h*ft2*F) 0.55 0.50 0.45 0.40 0.35 0.30 0.25 0.20 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 90% Krypton 60% Krypton 70% Krypton 80% Krypton 90% 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Double Glazed Low-e 0.04 Argon, Krypton and Xenon Fills Gas percentages represent fill gas concentration, initial fill rate was 90% Calculations performed using Window 5.2 computer program by WESTLab 0.60 Center-of-Glass U-factor (BTU/h*ft2*F) 0.55 0.50 0.45 0.40 0.35 0.30 0.25 0.20 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon Kyrpton Kr 80%-Ar 20% Kr 50%-Ar 50% Xenon 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Double Glazed Low-e 0.15 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.60 Center-of-Glass U-factor (BTU/h*ft2*F) 0.55 0.50 0.45 0.40 0.35 0.30 0.25 0.20 0.000 0.200 0.400 0.600 0.800 Glass Spacing (inches) Air Argon 90% Krypton 90% 1.000 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Double Glazed Low-e 0.15 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.60 Center-of-Glass U-factor (BTU/h*ft2*F) 0.55 0.50 0.45 0.40 0.35 0.30 0.25 0.20 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 60% Argon 70% Argon 80% Argon 90% Krypton 90% 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Double Glazed Low-e 0.15 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.60 Center-of-Glass U-factor (BTU/h*ft2*F) 0.55 0.50 0.45 0.40 0.35 0.30 0.25 0.20 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 90% Krypton 60% Krypton 70% Krypton 80% Krypton 90% 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Double Glazed Low-e 0.15 Argon, Krypton and Xenon Fills Gas percentages represent fill gas concentration, initial fill rate was 90% Calculations performed using Window 5.2 computer program by WESTLab 0.60 Center-of-Glass U-factor (BTU/h*ft2*F) 0.55 0.50 0.45 0.40 0.35 0.30 0.25 0.20 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon Kyrpton Kr 80%-Ar 20% Kr 50%-Ar 50% Xenon 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed One Low-e 0.04 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 Glass Spacing (inches) Air Argon 90% Krypton 90% 1.000 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed One Low-e 0.04 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 60% Argon 70% Argon 80% Argon 90% Krypton 90% 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed One Low-e 0.04 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 90% Krypton 60% Krypton 70% Krypton 80% Krypton 90% 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed One Low-e 0.04 Argon, Krypton and Xenon Gas percentages represent fill gas concentration, initial fill rate was 90% Calculations performed using Window 5.2 computer program by WESTLab 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon Kyrpton Kr 80%-Ar 20% Kr 50%-Ar 50% Xenon 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed One Low-e 0.15 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 Glass Spacing (inches) Air Argon 90% Krypton 90% 1.000 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed One Low-e 0.15 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 60% Argon 70% Argon 80% Argon 90% Krypton 90% 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed One Low-e 0.15 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 90% Krypton 60% Krypton 70% Krypton 80% Krypton 90% 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed One Low-e 0.15 Argon, Krypton and Xenon Gas percentages represent fill gas concentration, initial fill rate was 90% Calculations performed using Window 5.2 computer program by WESTLab 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon Kyrpton Kr 80%-Ar 20% Kr 50%-Ar 50% Xenon 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed Two Low-e 0.04 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 Glass Spacing (inches) Air Argon 90% Krypton 90% 1.000 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed Two Low-e 0.04 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 60% Argon 70% Argon 80% Argon 90% Krypton 90% 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed Two Low-e 0.04 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 90% Krypton 60% Krypton 70% Krypton 80% Krypton 90% 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed Two Low-e 0.04 Argon, Krypton and Xenon Gas percentages represent fill gas concentration, initial fill rate was 90% Calculations performed using Window 5.2 computer program by WESTLab 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon Kyrpton Kr 80%-Ar 20% Kr 50%-Ar 50% Xenon 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed Two Low-e 0.15 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 Glass Spacing (inches) Air Argon 90% Krypton 90% 1.000 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed Two Low-e 0.15 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 60% Argon 70% Argon 80% Argon 90% Krypton 90% 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed Two Low-e 0.15 Argon and Krypton Fills Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 90% Krypton 60% Krypton 70% Krypton 80% Krypton 90% 1.200 work sponsored Center-of-Glass U-factor (IP) vs. Glass Spacing Triple Glazed Two Low-e 0.15 Argon, Krypton and Xenon Gas percentages represent fill gas concentration, initial fill rate was 90% Calculations performed using Window 5.2 computer program by WESTLab 0.45 Center-of-Glass U-factor (BTU/h*ft2*F) 0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon Kyrpton Kr 80%-Ar 20% Kr 50%-Ar 50% Xenon 1.200 work sponsored by Center-of-Glass U-factor (IP) vs. Glass Spacing (20 degree) Double Glazed Low-e 0.04 Ar and Kr Gas percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 1.00 Center-of-Glass U-factor (BTU/h*ft2*F) 0.80 0.60 0.40 0.20 0.00 0.000 0.200 0.400 0.600 0.800 Glass Spacing (inches) Air Argon 90% Krypton 90% 1.000 1.200 work sponsored by Center-of-Glass U-factor (IP) vs. Glass Spacing (20 degree) Double Glazed Low-e 0.04 Ar and Kr Gas fill percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Windows 5.2 computer program by WESTLab. 1.00 Center-of-Glass U-factor (BTU/h*ft2*F) 0.80 0.60 0.40 0.20 0.00 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 60% Argon 70% Argon 80% Argon 90% Krypton 90% 1.200 work sponsored b Center-of-Glass U-factor (IP) vs. Glass Spacing (20 degree) Double Glazed Low-e 0.04 Ar and Kr Gas fill percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 1.00 Center-of-Glass U-factor (BTU/h*ft2*F) 0.80 0.60 0.40 0.20 0.00 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 90% Krypton 60% Krypton 70% Krypton 80% Krypton 90% 1.200 work sponsored b Center-of-Glass U-factor (IP) vs. Glass Spacing (20 degree) Double Glazed Low-e 0.04 Ar, Kr and Xe Gas fill percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 1.00 Center-of-Glass U-factor (BTU/h*ft2*F) 0.80 0.60 0.40 0.20 0.00 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon Kyrpton Kr 80%-Ar 20% Kr 50%-Ar 50% Xenon 1.200 work sponsored b Center-of-Glass U-factor (IP) vs. Glass Spacing (20 degree) Double Glazed Low-e 0.15 Ar and Kr Gas fill percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 1.00 Center-of-Glass U-factor (BTU/h*ft2*F) 0.80 0.60 0.40 0.20 0.00 0.000 0.200 0.400 0.600 0.800 Glass Spacing (inches) Air Argon 90% Krypton 90% 1.000 1.200 work sponsored by Center-of-Glass U-factor (IP) vs. Glass Spacing (20 degree) Double Glazed Low-e 0.15 Ar and Kr Gas fill percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Windows 5.2 computer program by WESTLab. 1.00 Center-of-Glass U-factor (BTU/h*ft2*F) 0.80 0.60 0.40 0.20 0.00 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 60% Argon 70% Argon 80% Argon 90% Krypton 90% 1.200 work sponsored b Center-of-Glass U-factor (IP) vs. Glass Spacing (20 degree) Double Glazed Low-e 0.15 Ar and Kr Gas fill percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 1.00 Center-of-Glass U-factor (BTU/h*ft2*F) 0.80 0.60 0.40 0.20 0.00 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon 90% Krypton 60% Krypton 70% Krypton 80% Krypton 90% 1.200 work sponsored b Center-of-Glass U-factor (IP) vs. Glass Spacing (20 degree) Double Glazed Low-e 0.15 Ar, Kr and Xe Gas fill percentages represent initial fill rates achieved, balance assumed to be air. Calculations performed using Window 5.2 computer program by WESTLab. 1.00 Center-of-Glass U-factor (BTU/h*ft2*F) 0.80 0.60 0.40 0.20 0.00 0.000 0.200 0.400 0.600 0.800 1.000 Glass Spacing (inches) Air Argon Kyrpton Kr 80%-Ar 20% Kr 50%-Ar 50% Xenon 1.200