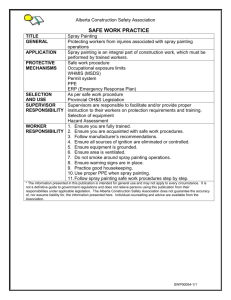

Spray painting code of practice

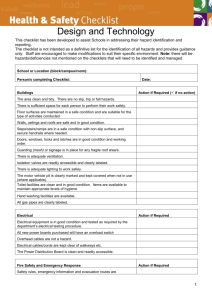

advertisement