VARIOPOX IMPREGNATING RESIN

advertisement

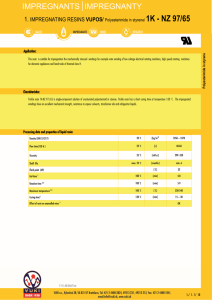

page 1 of 3 VARIOPOX IMPREGNATING RESIN DESCRIPTION Variopox Impregnating Resin is a two component epoxy system based on solvent free epoxy resins and polyamine adduct hardeners. PRINCIPAL CHARACTERISTICS • Suitable as general purpose epoxy system as adhesive, coating and laminating resin; • In combination with twaron, glass fibre or carbon fibre suitable as laminating resin; • Good resistance to various chemicals; • Good resistance to immersion in (salt) water; • Suitable as primer for EPS; • May be recoated with IJmopox ZF primer, IJmopox HB coating, Variopox Rolcoating or Double Coat. COLOURS AND GLOSS Transparent - High gloss BASIS PROPERTIES (AT Density Solid content Recommended d.f.t. Dust dry after Full cure after Recoating interval 23˚C AND 50% R.H.) : approx. 1,1 g/cm3 (mixed product) : approx. 100 % (volume) : depending on application : approx. 4 hours : approx. 2 days, see additional information : min. 24 hours, see additional information max. unlimited, provided clean and dry Shelf life : separate components, stored cool and dry in original packaging, minimum 6 months Flash point (DIN53213) : base component >100 ºC Hardener 112 ºC SPREADING RATE Depending on application : approx. 2,0 - 4,0 m2/kg (approx. 1,8 - 3,6 m2/l) The practical spreading rate depends on a number of variables, such as: shape and size of object to be painted, the condition and profile of the substrate, the method of application, climatologic conditions and skill of labour. SUBSTRATE CONDITION AND TEMPERATURE Wood : clean and dry, free from any contamination and loose particles, moisture content maximum 12%, pre-treated with Variopox Injection resin and sanded with grit paper P120; Other surfaces : clean and dry, in good condition, free from any contamination and loose particles, sanded with grit paper P120-180; During application and curing a minimum temperature of 15 ºC is allowed. The temperature of the substrate should be minimum 3 ºC above dew point. INSTRUCTIONS FOR USE Before use, mix base and hardener components thoroughly. Mixing ratio : 67,0 base : 33,0 hardener (by weight) 64,0 base : 36,0 hardener (by volume) Do not prepare more material than can be applied within the pot life of the mixture. VARIOPOX IMPREGNATING RESIN page 2 of 3 Induction time Pot life Application with: Type thinner % of thinner Nozzle orifice Nozzle pressure Cleaning : : none at 20 ºC 15 minutes at 25 ºC 20 minutes at 20 ºC 30 minutes at 15 ºC Brush/roller n.a. n.a. n.a. Double Coat Degreaser Do not mix Variopox Impregnating Resin with solvents. ADDITIONAL INFORMATION • Recoating and curing Variopox Impregnating Resin: Minimum, with IJmopox or Variopox, after sanding with grit paper P120 Minimum, with Double Coat, after sanding with grit paper P180 Minimum, with Double Coat Dubbel UV or Double Coat Karaat, after sanding with grit paper P180 Maximum, with IJmopox, Variopox or Double Coat, after sanding with grit paper P120-P180 Fully cured after • 15 oC 20 oC 15 oC 36 hours 24 hours 24 hours 3 days 2 days 2 days 14 days 14 days 14 days unlimited unlimited unlimited 4 days 2 days 2 days Mechanical properties: Property Value Unit Method flexural strength 60 MPa DIN 53452 deflection 2 mm DIN 53452 drukvastheid 120 MPa DIN 53454 E-modulus 3,500 MPa DIN 53457 o Tg temperature 42 C DIN 53458 elongation at break 2 % DIN 53455 compressive strength 70 KJ/m2 DIN 53453 tensile strength 30 MPa DIN 53455 Samples according DIN 53451, dimensions 120 x 15 x 10 mm, measured after 7 days curing at 23 oC • Pot life Do not continue application when the pot life is about to end. As the reaction between base and hardener has progressed, a poor adhesion will be the result. • Application of Variopox Impregnating Resin at lower temperatures: Curing at temperatures lower than 15 ºC will result in a sticky layer on top of the cured resin. This will negatively affect adhesion of following coatings. page 3 of 3 VARIOPOX IMPREGNATING RESIN SAFETY INFORMATION See the corresponding Material Safety Data Sheet for detailed instructions on safety, disposal and health. Date: September ’14 322-99999 Disclaimer Although the information and recommendations are presented in good faith and believed to be correct at date of issue, De IJssel Coatings B.V. makes no representations as of the completeness or accuracy thereof. In no event De IJssel Coatings B.V. will be responsible for damages of any nature whatsoever resulting from the use of this information.