Energy Solutions Impregnating Resins

advertisement

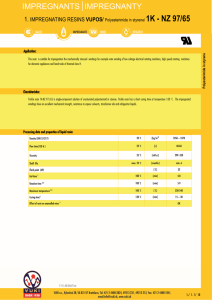

A X A LTA C O AT I N G S Y S T E M S Special Properties Shelf Life / Storage Time Flow Time DIN 53211 Thermal Class Product Energy Solutions Impregnating Resins Product Overview acc. to IEC 60085(1) 23 °C [sec.] 25 °C [months] Voltatex® 2010 – 30 – 40 24 Voltatex® 2020 red – 75 – 125 8 Quick single component air drying pigmented finishing varnish with excellent adhesion on metals and plastics, suitable as additional protection against external influences and corrosion, especially against humidity. Voltatex® 2020 grey – 155 – 75 12 Quick single component air drying pigmented finishing varnish with excellent adhesion on metals and plastics, suitable as additional protection against external influences and corrosion, especially against humidity. 180 (H) 65 – 95 12 Clear, fast curing ready-to-use varnish, thermosetting, delivers a hard and elastic compound with resistances against solvent gases, transformer oil, climate stresses, fungal investigation and acids, suds and ammonia. Energy Solutions Impregnating Resins Finishing Varnish Quick single component air drying clear finishing varnish with excellent adhesion on metals and plastics, suitable as additional protection against external influences and corrosion. Product Overview Impregnating Varnish Voltatex® 2100 Thinner Voltatex® 5022 Voltatex® 5022 can be added to the Impregnating Varnish Voltatex® 2100 to adjust the required viscosity. Voltatex® 5023 Voltatex® 5023 can be added to Finishing Varnishes ( Voltatex® 2020 Series ) to adjust the required viscosity. Reactive Thinner Voltatex® 5031 Voltatex® 5031 can be added to Impregnating Resins ( Voltatex® 4000 Series ) to adjust the required viscosity. Voltatex® 5032 Voltatex® 5032 can be added to Impregnating Resins ( Voltatex® 4100 Series ) to adjust the required viscosity. Cleaning Agent Voltatex® 5050 Voltatex® 5050 is a clear, transparent solvent mixture with excellent cleaning properties. Service Products Voltatex® 5140 1K Hardener Voltatex® 5140 is mixed into Voltatex®-Impregnating Resins based on unsaturated polyester / polyester imide chemistry for adjusting the reactivity. Voltatex® 5151 Catalyst Voltatex® 5151 is mixed into Voltatex®-Impregnating Resins based on unsaturated polyester / polyester imide chemistry for curing at low temperature. Voltatex® 5341 Accelerator Voltatex® 5341 is mixed into Voltatex®-Impregnating Resins based on unsaturated polyester / polyester imide chemistry for cold curing. Axalta Coating Systems Germany GmbH & Co. KG Energy Solutions Technical Service Christbusch 25 D-42285 Wuppertal Phone:+49 202 529-23 87 -24 92 Fax: +49 202 529-28 21 (1) based on Temperature Index MW 35, Twisted Pair www.voltatex.com 13,5 – 27,5 X X X 20,0 – 35,0 25,0 – 45,0 X X X - - - 4010 5,0 – 8,0 7,0 – 12,0 X 7,9 - - - 4012 5,0 – 7,5 7,5 – 11,5 X 18,5 - - - 4014 5,0 – 7,5 7,0 – 12,0 X 180 (H) X Unsat. Polyesterimide 55 - 75 210 - 270 8 6,6 - 200 (N) X Unsat. Polyesterimide (2) 35 - 50 120 - 180 8 8 - 180 (H) X Unsat. Polyesterimide (3) 38 - 48 150 - 190 8 9,7 (3) 58 - 72 220 - 260 8 18 - 20 35 - 65 8 Voltatex 4002 Voltatex® 4005 Voltatex® 4010 VOC - free - Pigmented - Thixotropic 6,8 UL 8 High Voltage Applications < 6,6 kV UN 9,0 – 15,0 4005 210 - 270 Windgenerators, < 1000 V 4002 - 55 - 75 Stators, dipping, Hot Dip/Gel Process - - Unsat. Polyesterimide 200 (N) Stators, dipping, Electrical/UV-Process - X Voltatex® 4001 Stators, dipping, combined curing electrically and oven X - Stators / Rotors up to 3 kV, VPI Process X - Stators, Dip & Bake Process X - Stators, trickle 13,5 – 27,5 10 Rotors, high speed 8,0 – 14,5 8 Rotors 4001 340 - 400 X Transformer >100 kVA - 75 - 95 180 (H) Low draining and evaporation losses, high bond strength, high resin retention, good resistance against solvent vapour, high thermal resistance; low tendency to crack High efficiency due to favorable curing conditions and low material consumption, good resistance against solvent vapour, high thermal resistance, low tendency to crack High efficiency due to favorable curing conditions and low material consumption, good resistance against solvent vapour, high thermal resistance High efficiency due to favorable curing conditions and low material consumption, good resistance against solvent vapour, high thermal resistance High efficiency due to favorable curing conditions and low material consumption, good resistance against solvent vapour, high thermal resistance High efficiency due to favorable curing conditions, and low material consumption, good resistance against solvent vapour, high thermal resistance; applicable by trickle-roll-process High efficiency due to favorable curing conditions, and low material consumption, good resistance against solvent vapour, high thermal resistance; applicable by hot-dip-process High efficiency due to favorable curing conditions, and low material consumption, good resistance against solvent vapour, high thermal resistance; applicable by hot-dip-process Enables coverage of flash rust by use of coloured resin, protection against climate influences; high efficiency, good resistance against solvent vapour, good thermal resistance Enables coverage of flash rust by use of coloured resin, protection against climate influences; high efficiency, good resistance against solvent vapour Low draining and evaporation losses, high bond strength, high resin retention, good resistance against solvent vapour, high thermal resistance; low tendency to crack Gel-coat for protection of rotor windings exposed to high mechanical stress, high bond strength and protection against abrasion; good adhesion Applicable in the Electrical/UV-Process, high resin retention, good resistance against solvent vapour 4000 4001 4002 4005 4010 4012 4014 4015 4020 4021 4030 4040 4050 High efficiency due to favorable curing conditions and low material consumption; very good resin retention; high thermal resistance, styrene free High efficiency due to favorable curing conditions and low material consumption; excellent resin retention; high thermal resistance, styrene free Gel-coat for protection of rotor windings exposed to high mechanical stress, high bond strength and protection against abrasion; good adhesion, low tendency to crack 4100 4130 4141 Low emission, VOC-free, styrene free, high thermal and mechanical endurance even under long term stress; good resistance against solvent vapour, resistant to refrigerants Low emission; high thermal and mechanical endurance; very good adhesion, tough and hard; applicable in dip-roll-process Low emission, VOC-free, styrene free, very good adhesion, high thermal and mechanical endurance; good elasticity, very good dielectric properties Very low viscous, low emission resin, VOC-free, very low tendency to crack, very good adhesion; contains renewable raw materials, also applicable in dip-roll-processes Excellent resin retention and high efficiency due to thixotropic formulation, high thermal and mechanical endurance even under long term stress Applicable in the Electrical/UV-Process, low emission, VOC-free, styrene free, high thermal and mechanical endurance even under long term stress; resistant to refrigerants Higher reactive formulation of Voltatex® 4250, VOC-free 4200 4201 4202 4204 4230 4250 4252 Monomer free, low emission resin; low smell; VOC-free; high viscous; low tendency to crack, very good elasticity Monomer free, low emission resin; low smell; VOC-free; high viscous; low tendency to crack, very good elasticity Monomer free, low emission resin; low smell; VOC-free; high viscous; low tendency to crack, very good elasticity Monomer free, low viscous, low emission resin; low smell; VOC-free; low tendency to crack, good adhesion Dip & Bake formulation of Voltatex® 4310, VOC-free 4300 4301 4302 4303 4305 Transformer <100 kVA X Unsat. Polyesterimide Voltatex® 4000 Voltatex® VPI Vacuum Pressure Impregnation X [%] Special Properties VI Vacuum Impregnation X 25°C [months] Trickle Dip & Bake (conventional) 10,0 – 25,0 25°C [mPas] E101752 Hot-Dip/Gel inside resin Reaction Time 7,0 – 14,0 23°C [sec.] acc.to IEC 60085(1) Voltatex® Gel Time Emissions DIN EN 60455-3-5 4000 Shelf Life / Storage Time [min] (5) Viscosity DIN 53019 [min] (5) Flow Time DIN 53211 Chemical Base Thermal Class Product Energy Solutions Impregnating Resins Product Overview Styrene-diluted ® Voltatex 4012 200 (N) X Unsat. Polyesterimide Voltatex® 4014 200 (N) X Unsat. Polyesterimide (3) Voltatex 4015 200 (N) X Unsat. Polyesterimide 27 - 33 70 - 90 8 13,8 - - - 4015 5,0 – 8,0 7,0 – 12,0 Voltatex® 4020 200 (N) X Unsat. Polyesterimide 45 - 75 210 - 270 4 11,7 - X - 4020 11,0 – 19,0 22,0 – 40,0 X X X Voltatex® 4021 200 (N) X Unsat. Polyesterimide 25 - 35 75 - 125 4 12,2 - X - 4021 10,0 – 16,0 26,0 – 40,0 X X X Voltatex 4030 180 (H) X Unsat. Polyesterimide 81 - 99 350 - 500 4 5,9 X - - 4030 10,0 – 15,0 15,0 – 23,0 X X X Voltatex® 4040 180 (H) - Unsat. Polyesterimide - 1500 - 1900 4 6,0 - X - 4040 6,0 – 12,0 10,0 – 22,0 Voltatex® 4050 180 (H) X Unsat. Polyesterimide 55 – 75 230 - 270 8 13,7 - - 4050 5,5 – 9,5 9,0 – 16,0 X X X ® ® ® (3) X X X Vinyltoluene (VT)-diluted Voltatex® 4100 180 (H) X Unsat. Polyesterimide 57 - 73 220 - 280 6 5,7 - - - 4100 6,0 – 12,0 14,0 – 24,0 X X X Voltatex 4130 180 (H) X Unsat. Polyesterimide 65 - 85 235 - 295 6 5,2 X - - 4130 6,0 – 10,0 10,0 – 17,0 X X X Voltatex® 4141 - - Unsat. Polyesterimide - 4000 - 6000 4 1,6 - X - 4141 13,0 – 21,0 16,0 – 28,0 Voltatex® 4200 220 (R) X Unsat. Polyesterimide - 1800 - 2700 6 1,2 - - X 4200 7,0 – 13,0 8,0 – 16,0 X X Voltatex 4201 220 (R) X Unsat. Polyesterimide - 700 - 1100 8 2,4 - - - 4201 7,0 – 13,0 8,0 – 15,0 X Voltatex® 4202 180 (H) X Unsat. Polyester - 1900 - 2600 8 2,2 - - X 4202 9,0 – 15,0 11,0 – 18,0 X Voltatex® 4204 180 (H) X Unsat. Polyesterimide - 290 - 340 6 1,7 - - X 4204 8,5 – 10,0 10 – 12,0 Voltatex 4230 220 (R) X Unsat. Polyesterimide Voltatex® 4250 220 (R) X Unsat. Polyesterimide Voltatex 4252 220 (R) - Unsat. Polyesterimide ® X Low Emission ® ® ® (4) (4) (3) X X X X X X X X X X X - 700 - 1300 6 1,4 X - - 4230 9,5 – 15,0 10,0 – 16,0 X X X - 1900 - 2600 6 1,7 - - X 4250 7,5 – 13,5 8,5 – 14,5 X X X X - 1900 - 2600 6 1,4 - - X 4252 6,0 – 12,0 10,0 – 16,0 X X X X Monomer free / VOC-minimised Voltatex® 4300 180 (H) - Unsat. Polyesterimide - 6300 - 7700 6 0,5 - - X 4300 6,0 – 16,0 7,0 – 17,0 X X Voltatex 4301 180 (H) - Unsat. Polyesterimide - 5000 - 7000 8 1 - - X 4301 10,0 – 16,0 15,0 – 24,0 X X Voltatex® 4302 180 (H) - Unsat. Polyesterimide - 6300 - 7700 12 0,5 - - X 4302 25,0 – 60,0 – X X ® Voltatex 4303 180 (H) X Unsat. Polyesterimide - 700 - 1100 8 0,5 - - X 4303 9,0 – 15,0 10,0 – 17,0 X Voltatex® 4305 180 (H) X Unsat. Polyesterimide (4) - 650 - 1200 6 3,4 - - X 4305 10,0 – 15,0 16,0 – 22,0 X Voltatex 4310 180 (H) Voltatex® 4311 180 (H) ® ® X X Unsat. Polyesterimide (3)(4) - 800 - 1200 4 2 - - - 4310 4,5 – 7,5 5,0 – 10,0 X X Unsat. Polyesterimide (3)(4) - 800 - 1200 4 2 - - - 4311 5,5 – 8,5 6,5 – 11,5 X based on Temperature Index MW 35, Twisted Pair curing by peroxide (3) highly reactive contains a small portion of reactive thinner to optimize the viscosity company standard Energy Solutions - Voltatex® 001 “Measurement of Gel Time” in acc. with DIN 46448 (6) under consideration (1) (4) (2) (5) Low emission resin, contains a small portion of reactive thinner to optimize viscosity, good adhesion; very high thermal and mechanical endurance Low emission resin, contains a small portion of reactive thinner, very high bond strength, very good adhesion; low tendency to crack; highest thermal and mechanical endurance 4310 4311 = recommended = suitable = not recommended April 2016