FOCUS | NEWS & VIEWS

CRYSTAL–CRYSTAL TRANSITIONS

Mediated by a liquid

The nucleation of a crystal within another can involve intermediate liquid nuclei.

Eduardo Sanz and Chantal Valeriani

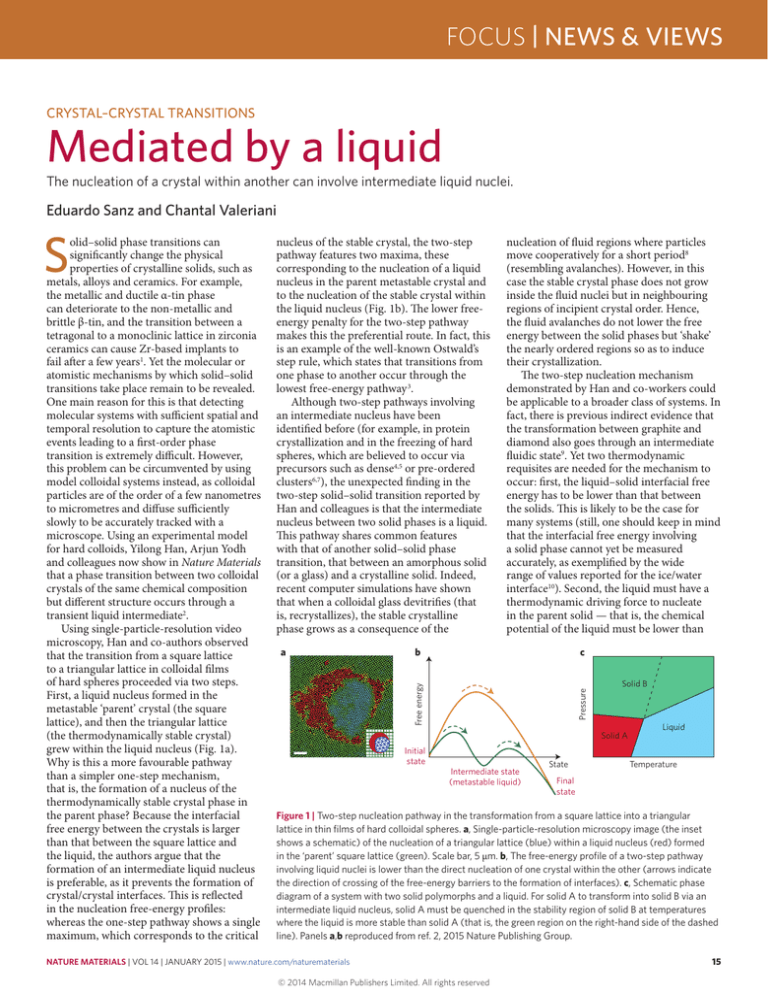

nucleus of the stable crystal, the two-step

pathway features two maxima, these

corresponding to the nucleation of a liquid

nucleus in the parent metastable crystal and

to the nucleation of the stable crystal within

the liquid nucleus (Fig. 1b). The lower freeenergy penalty for the two-step pathway

makes this the preferential route. In fact, this

is an example of the well-known Ostwald’s

step rule, which states that transitions from

one phase to another occur through the

lowest free-energy pathway 3.

Although two-step pathways involving

an intermediate nucleus have been

identified before (for example, in protein

crystallization and in the freezing of hard

spheres, which are believed to occur via

precursors such as dense4,5 or pre-ordered

clusters6,7), the unexpected finding in the

two-step solid–solid transition reported by

Han and colleagues is that the intermediate

nucleus between two solid phases is a liquid.

This pathway shares common features

with that of another solid–solid phase

transition, that between an amorphous solid

(or a glass) and a crystalline solid. Indeed,

recent computer simulations have shown

that when a colloidal glass devitrifies (that

is, recrystallizes), the stable crystalline

phase grows as a consequence of the

a

nucleation of fluid regions where particles

move cooperatively for a short period8

(resembling avalanches). However, in this

case the stable crystal phase does not grow

inside the fluid nuclei but in neighbouring

regions of incipient crystal order. Hence,

the fluid avalanches do not lower the free

energy between the solid phases but ‘shake’

the nearly ordered regions so as to induce

their crystallization.

The two-step nucleation mechanism

demonstrated by Han and co-workers could

be applicable to a broader class of systems. In

fact, there is previous indirect evidence that

the transformation between graphite and

diamond also goes through an intermediate

fluidic state9. Yet two thermodynamic

requisites are needed for the mechanism to

occur: first, the liquid–solid interfacial free

energy has to be lower than that between

the solids. This is likely to be the case for

many systems (still, one should keep in mind

that the interfacial free energy involving

a solid phase cannot yet be measured

accurately, as exemplified by the wide

range of values reported for the ice/water

interface10). Second, the liquid must have a

thermodynamic driving force to nucleate

in the parent solid — that is, the chemical

potential of the liquid must be lower than

b

c

Pressure

Free energy

S

olid–solid phase transitions can

significantly change the physical

properties of crystalline solids, such as

metals, alloys and ceramics. For example,

the metallic and ductile α-tin phase

can deteriorate to the non-metallic and

brittle β-tin, and the transition between a

tetragonal to a monoclinic lattice in zirconia

ceramics can cause Zr-based implants to

fail after a few years1. Yet the molecular or

atomistic mechanisms by which solid–solid

transitions take place remain to be revealed.

One main reason for this is that detecting

molecular systems with sufficient spatial and

temporal resolution to capture the atomistic

events leading to a first-order phase

transition is extremely difficult. However,

this problem can be circumvented by using

model colloidal systems instead, as colloidal

particles are of the order of a few nanometres

to micrometres and diffuse sufficiently

slowly to be accurately tracked with a

microscope. Using an experimental model

for hard colloids, Yilong Han, Arjun Yodh

and colleagues now show in Nature Materials

that a phase transition between two colloidal

crystals of the same chemical composition

but different structure occurs through a

transient liquid intermediate2.

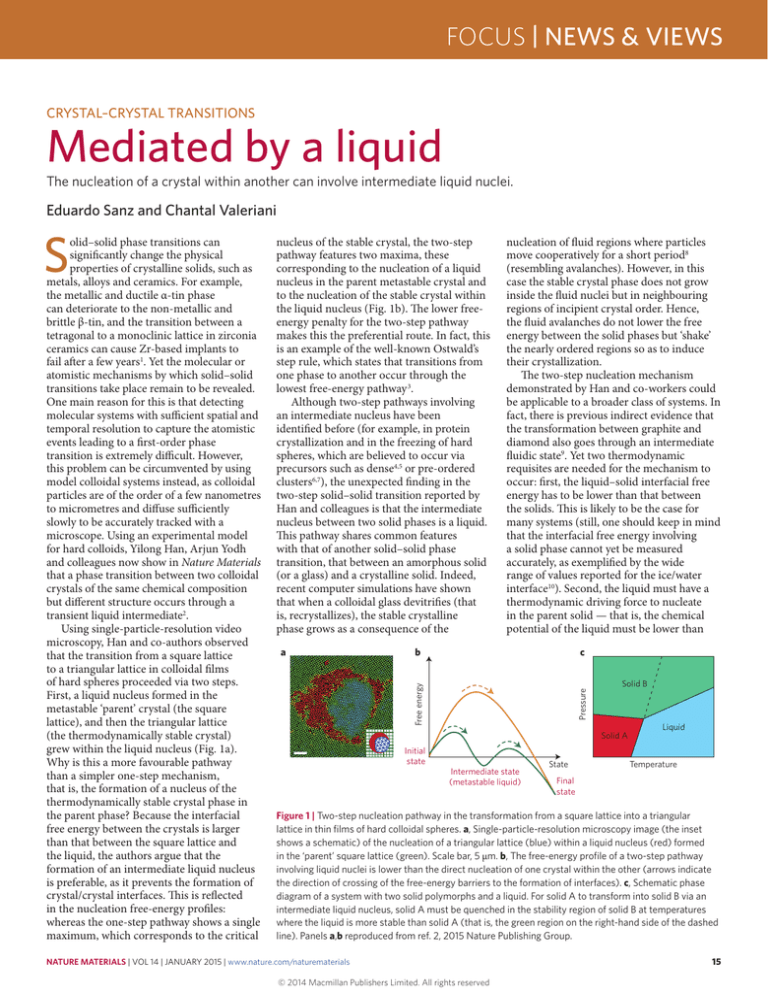

Using single-particle-resolution video

microscopy, Han and co-authors observed

that the transition from a square lattice

to a triangular lattice in colloidal films

of hard spheres proceeded via two steps.

First, a liquid nucleus formed in the

metastable ‘parent’ crystal (the square

lattice), and then the triangular lattice

(the thermodynamically stable crystal)

grew within the liquid nucleus (Fig. 1a).

Why is this a more favourable pathway

than a simpler one-step mechanism,

that is, the formation of a nucleus of the

thermodynamically stable crystal phase in

the parent phase? Because the interfacial

free energy between the crystals is larger

than that between the square lattice and

the liquid, the authors argue that the

formation of an intermediate liquid nucleus

is preferable, as it prevents the formation of

crystal/crystal interfaces. This is reflected

in the nucleation free-energy profiles:

whereas the one-step pathway shows a single

maximum, which corresponds to the critical

Solid B

Solid A

Initial

state

Intermediate state

(metastable liquid)

State

Liquid

Temperature

Final

state

Figure 1 | Two-step nucleation pathway in the transformation from a square lattice into a triangular

lattice in thin films of hard colloidal spheres. a, Single-particle-resolution microscopy image (the inset

shows a schematic) of the nucleation of a triangular lattice (blue) within a liquid nucleus (red) formed

in the ‘parent’ square lattice (green). Scale bar, 5 μm. b, The free-energy profile of a two-step pathway

involving liquid nuclei is lower than the direct nucleation of one crystal within the other (arrows indicate

the direction of crossing of the free-energy barriers to the formation of interfaces). c, Schematic phase

diagram of a system with two solid polymorphs and a liquid. For solid A to transform into solid B via an

intermediate liquid nucleus, solid A must be quenched in the stability region of solid B at temperatures

where the liquid is more stable than solid A (that is, the green region on the right-hand side of the dashed

line). Panels a,b reproduced from ref. 2, 2015 Nature Publishing Group.

NATURE MATERIALS | VOL 14 | JANUARY 2015 | www.nature.com/naturematerials

© 2014 Macmillan Publishers Limited. All rights reserved

15

NEWS & VIEWS | FOCUS

that of the parent solid). This condition

may not be satisfied generally because the

chemical potential of the liquid depends

on thermodynamic conditions (Fig. 1c).

If the liquid is less stable than the parent

solid (that is, if it has a higher chemical

potential), the solid–solid transition would

most likely occur through a diffusionless

martensitic route.

Experiments and computer simulations

of model colloidal particles are ideal for

investigating whether solid–solid transition

pathways depend on thermodynamic

conditions, and can also provide clues on

phase-transition mechanisms in atomic

or molecular systems11,12. Still, accurate

knowledge of the equilibrium phase diagram

MATERIAL WITNESS

16

is required, which is difficult to achieve

experimentally. In this respect, simulations

can provide useful guidance13 — in fact,

the stability range for the triangular and

square lattices had been predicted earlier 14.

With advances in particle synthesis, video

microscopy and the characterization

of model colloidal systems, one would

expect that the effects of constant pressure,

particle asymmetry and particle softness —

conditions that are generally more

realistic — will soon be evaluated.

❐

Eduardo Sanz and Chantal Valeriani are in the

Departmento de Química-física I, Universidad

Complutense de Madrid, 28040 Madrid, Spain.

e-mail: esa01@quim.ucm.es

References

1. Shen, J. Z. & Kosmač, T. (eds) Advanced Ceramics for Dentistry

(Elsevier, 2014).

2. Peng, Y. et al. Nature Mater. 14, 101–108 (2015).

3. Ostwald, W. Z. Physik. Chem. 22, 289–330 (1897).

4. ten Wolde, P. R. & Frenkel, D. Science 277, 1975–1978 (1997).

5. Schilling, T., Schope, H. J., Oettel, M., Opletal, G. & Snook, I.

Phys. Rev. Lett. 105, 025701 (2010).

6. Kawasaki, T. & Tanaka, H. Proc. Natl Acad. Sci. USA

107, 14036–14041 (2010).

7. Tan, P., Xu, N. & Xu, L. Nature Phys. 10, 73–79 (2014).

8. Sanz, E. et al. Proc. Natl Acad. Sci. USA 111, 75–80 (2014).

9. Shekar, N. C. & Rajan, K. G. Bull. Mater. Sci.

24, 1–21 (2001).

10. Prupacher, H. R. J. Atmosph. Sci. 52, 1924–1933 (1995).

11. Khaliullin, R. Z., Eshet, H., Kühne, T. D., Behler, J. &

Parrinello, M. Nature Mater. 10, 693–697 (2011).

12. Sanz, E. et al. J. Am. Chem. Soc. 135, 15008–15017 (2013).

13. Vega, C., Sanz, E., Abascal, J. L. F. & Noya, E. G.

J. Phys. Condens. Matter 20, 153101 (2008).

14. Fortini, A. & Dijkstra, M. J. Phys. Condens. Matter

18, L371–L378 (2006).

THE FINAL CUT

Origami — the folding of flat sheets —

has been a well-advertised approach

to engineering structures with diverse

properties that can be efficiently and

easily collapsed and unfolded1. But

there is another constructive paper art

in Far East Asia that has received less

attention: kirigami, in which paper

is cut into intricate patterns. This

approach often involves folding too:

the archetypal kirigami form is a scene,

often a building, made from strips and

facets that emerge from the hinge of a

folded sheet.

Although kirigami is essentially

of Japanese origin, it has long been

familiar throughout the world in the

form of the snowflake decoration

made by folding and nicking a

sheet (a method sadly apt to yield

snowflakes with four-fold rather

than six-fold symmetry). Paper-cut

snowflakes — simply outlines rather

than genuine kirigami — featured

in one of the first serious studies of

their forms, Cloud Crystals (1864)

by the keen-eyed American amateur

Frances Chickering.

Kirigami has, however, so far

enjoyed scant attention in materials

science — among rare examples,

there has been interest in applying its

methods at the nanoscale to graphene

to alter its mechanical properties2,3.

Now, Cho et al. have attempted to

give kirigami engineering a more

systematic conceptual basis4. They

describe a general approach for

enabling a sheet of flexible material

to adopt an arbitrary geometry by

reverse-engineering the system of

cuts needed to attain it. No folding is

employed here: the deformations of

the sheet come solely from making a

series of slits that fragment the sheet

into smaller blocks connected at their

corners, which will then rotate under

tension so that the blocks open out

into an expanded network.

In general these blocks might be

squares or triangles. Their rotation

depends on leaving a small amount of

material at the ends of the cuts, and on

these hinges being sufficiently flexible

to deform while strong enough not

to simply tear. The design parameters

here are material-dependent: the

researchers demonstrate their ideas

with elastomeric sheets, but say

that metals might be used if the

hinge stresses can be kept below the

yield strength.

The amount of expansion of the

fabric (shown here to reach up to

800%) can be adjusted by imposing

a fractal hierarchy on the cuts. Each

square block, say, can be divided

into smaller squares and so forth. By

varying the degree of the hierarchy

from place to place, the sheet can

adopt all kinds of curved grid-like

geometry, including non-Euclidean

ones. As a demonstration, Cho et al.

cut a silicone rubber sheet, coated with

a layer of carbon nanotubes to make

it electrically conducting, so that it

PHILIP BALL

can be wrapped around a baseball

without wrinkles while retaining the

connectivity that enables it to wire

up a light-emitting diode across the

ball’s surface.

There is an echo here of the reverse

problem of projecting the Earth

onto a flat world map. Cho et al.’s

method of covering a sphere with a

sheet is certainly more elegant than

the ungainly Goode homolosine

cartographic projection, with its

awkward rents in the oceans — but

at the considerable cost, perhaps, of

fragmenting the surface into countless

little pieces.

❐

References

1. Schenk, M. & Guest, S. D. in Origami 5: Fifth

International Meeting of Origami Science, Mathematics,

and Education (eds Wang-Iverson, P., Lang, R. J. &

Yim, M.) 293–305 (CRC Press, 2011).

2. Blees, M., Rose, P., Barnard, A., Roberts, S. &

McEuen, P. L. Bull. Am. Phys. Soc.

59, abstr. L30.00011 (2014).

3. Qi, Z., Park, H. S. & Campbell, D. K. Preprint at

http://arxiv.org/abs/1407.8113 (2014).

4. Cho, Y. et al. Proc. Natl Acad. Sci. USA http://dx.doi.org/

10.1073/pnas.1417276111 (2014).

NATURE MATERIALS | VOL 14 | JANUARY 2015 | www.nature.com/naturematerials

© 2014 Macmillan Publishers Limited. All rights reserved