Surge arresters - Electrical Engineering Book

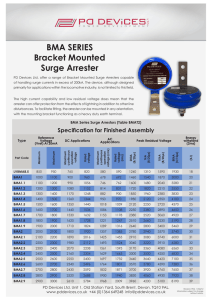

advertisement