Analysis of Different PM Machines with Concentrated Windings and

advertisement

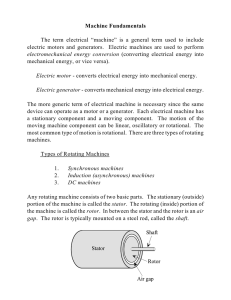

Analysis of Different PM Machines with Concentrated Windings and Flux Barriers in Stator Core Gurakuq Dajaku, Dieter Gerling Abstract - The new stator structure with magnetic flux-barriers in the stator yoke or tooth region represents an efficient method for reducing the sub-harmonics of electric machines with fractional slots, tooth-concentrated windings. In this paper the both flux-barriers techniques are considered during the analysis of different PM machines. The 12-teeth single-layer and double-layer concentrated winding in combination with a 10-poles and 14-poles PM rotor are investigated. For the all machine topologies the new stator design is used to improve their performances and characteristics. The flux-barrier effects on the main machine parameters, such as in the air-gap flux density harmonics, dq-machine parameters, characteristic currents, electromagnetic torque, and so on, are studied carefully. Comparisons performed with the analogous conventional machines (with conventional stator) show that, the new stator design offers significant advantages. Φ Index Terms— Tooth concentrated winding, MMF harmonics, magnetic flux-barrier, permanent magnet synchronous machines, finite elements method. I. INTRODUCTION RACTIONAL slot tooth concentrated windings (FSCW) are widely using by permanent magnet (PM) synchronous machines. Especially for the applications where the available space and packaging is limited, at the moment this winding type appears to be a single solution. Recently, the FSCW are usually used by PM machines, however the interest on this winding type are growing up also for others electric machine types such as synchronous reluctance machines [1, 2] and asynchronous machines [3, 4]. The use of concentrated windings offers several advantages which are discussed and studied widely in many literatures [5-7], however they are related also with some drawbacks such as the high losses in rotor (iron core and permanent magnets) [8 to 10], and the noise and vibration effects [11 to 13]. It is important to point out that these negative effects results mostly from the nonsinusoidal distribution of the magneto motive force (MMF) distribution produced from the stator winding. With other words, the magnetic field of these windings has more space harmonics, including sub-harmonics. For the PM machines, the torque is developed by the interaction of a specific high stator space harmonic with the corresponding number of F G. Dajaku is Senior Scientist with FEAAM GmbH, D-85577 Neubiberg, Germany (e-mail: Gurakuq.Dajaku@unibw.de). D. Gerling is Full Professor at the University of Federal Defense Munich, Institute for Electrical Drives, D-85577 Neubiberg, Germany (e-mail: Dieter.Gerling@unibw.de). 978-1-4799-4775-1/14/$31.00 ©2014 IEEE permanent magnet poles in rotor, however, the rest of others sub- and high harmonics, which rotate with the different speed and also in opposite directions, lead to undesirable effects in the machine. Analogous, also for the asynchronous machines, the winding harmonics induce additional rotor currents and opposing torques with limited net torque and high rotor bar losses compared to a conventional distributed winding. Therefore, to improve the MMF winding performances of the FSCW regarding to power losses and noise problems several methods and techniques are developed and investigated in the past [14 to 23]. Generally, according to these methods, the air-gap flux density harmonics produced from the winding MMF can be reduced or completely suppressed by modifying the winding layout [14, 21] or using magnetic flux barriers in some specific stator core locations [22, 23]. The investigations carried out through these works show that using different optimizations techniques brings enormous improvements on the PM machine performances such as reduction of the sub- and high MMF harmonics more than 60%, reduction of radial force modes of low order, reduction of the machine losses (magnet losses, iron losses and so on), improves the cooling capability (direct cooling of coil windings), reduce the slot proximity effects, and so on. In this paper, the new stator structure with magnetic flux-barriers in stator core region (yoke and teeth) is considered during the analysis of different PM machines with concentrated windings. The widely used 12-teeth single-layer (SL) and double-layer (DL) windings are taken as exemplary windings for different 10-poles and 14-poles machine designs. The main objective of this work was to investigate the flux-barrier effect on their main machine parameters such as the electromagnetic torque, inductances, flux-linkage, and also on the field weakening capability. The design and analysis of the studied machines is performed using 2D finite elements method (FEM). For the all exemplary machines, several steady state and in time-domain simulations are performed and also different load conditions are investigated, and finally the obtained results are compared with the analogous conventional stator designs. II. THE 12-TEETH TOOTH CONCENTRATED WINDING Using FSCW, there are many possible slot number and pole number combinations for PM machines. The stator coils may be wound either on all the teeth (double layer winding, DL) or only on alternate teeth (single-layer winding, SL). Fig. 1 shows different concentrated winding layouts wound in a 12-teeth stator core. SL winding have coils wound only on alternate teeth, whereas each tooth of the DL windings carries 375 a coil. The winding layout and the winding factor of a PM machine with concentrated winding depend on its combination of pole and slot number. Therefore, this combination should be chosen carefully in order to maximize the fundamental (MMF working harmonic) winding factor and thus the torque density. SL windings are preferred to DL windings when a high fundamental winding factor and high fault-tolerance is required. Otherwise, DL windings are preferable to limit the losses and torque ripple. A. Winding Function Analysis The MMF distribution for one-phase of considered windings are illustrated in the following Fig. 2. Using Fourier series function the MMF distribution can be described using the following eqs. (1) and (2). ν ν =1,3,5,... πν ⋅ i ⋅ cos ( νφS ) ⎛ π⎞ ξ w ,SL = sin ⎜ ν ⎟ ⎝ 12 ⎠ Θ DL (φS , t) = ν 4 ⋅ N w1 ⋅ ξ w ,SL ∑ ξ w ,DL 8 ⋅ N w 2 ⋅ ν ξ w ,DL ν =1,3,5,... πν ⋅ i ⋅ cos ( νφS ) ⎛ 5π ⎞ ⎛ π⎞ = cos ⎜ ν ⎟ ⋅ sin ⎜ ν ⎟ ⎝ 12 ⎠ ⎝ 12 ⎠ π (2) π/6 where, with ν ξ w is denoted the winding factor, i is the phase current, ω is the angular frequency, Nw is the number of turns per coil, and ν are the MMF winding harmonic. The indexes SL and DL are used for the single-layer and double-layer winding, respectively. Fig. 3 compares the harmonic contents of the considered FSCW types, however, Table-I show the winding factors for the first three harmonics in the MMF spectrum. As can be seen here, the main difference between the presented winding types is not only in the winding layout, but also on the MMF spectrum. For the SL winding, the winding factors for the 5th, 7th (possible working harmonics) are for about 3.3% higher compared with the DL winding, that means, regarding to the torque density the SL winding overcome the analogous DL winding. However, the 1st MMF sub-harmonic for the SL winding is relatively too high which induce huge losses in the rotor core and magnets [8-10] and thus it decreases the torque density and the efficiency of the machine. Therefore, as results of high rotor losses, the PM machines with the DL winding are mostly used in many applications. TABLE-I: Winding factors ν ξw Nw ⋅ i (1) x ∞ ∑ b) Θ(x) st th th SL 1 25.8% 5 96.6% 7 96.6% DL 6.7% 93.3% 93.3% Θ(x) Nw ⋅ i x π π/6 Fig. 2: MMF distribution of one phase, a). SL winding, b). DLwinding. 1.4 Single-Layer Double-Layer 1.2 5th or 7th =>working harmonics 1 MMF [ p.u. ] ΘSL (φS , t) = ν ∞ a) Fig. 1: Available winding layouts for the 12-teeth FSCW, a). SL winding, b). DL winding. 0.8 0.6 0.4 0.2 0 1 3 5 7 9 11 13 Space Harmonics 15 17 19 Fig. 3: MMF winding harmonics for the 12-teeth SL and DL FSCW. 376 B. Reduction of sub-harmonics using flux-barriers in stator core region Let’s remind here that, except the well know conventional FSCW with q=0.5 (+A,+B,+C), the rest of others concentrated windings use the high MMF harmonics as working harmonic. This is shown also from the previous Table-I and Fig. 3, where the high harmonics, such as the 5th and the 7th, have the highest winding factors. On the other side, the harmonics of low orders such as the 1st one rotate with different speed referred to the fundamental harmonic, and due to the large wave length they flow deeply inside the rotor region and induce there large rotor losses in the iron core and also in magnets. Therefore, to reduce the effects of sub-harmonics in PM machines with FSCWs, references [22 and 23] show two new stator structures with magnetic flux barriers in specific stator core locations which are illustrated in Fig. 4. For the 12-teeth/10-poles PM machine the new stator structure with flux barriers in the yoke regions beside every second stator slot present an efficiency solution for the both winding layouts. However, another alternative solution using flux barriers on the teeth region (every second teeth) is also an efficient and promising technique for the 12-teeth/14-poles PM machine with the SL winding. 110 BvFB / BvConv [ % ] 100 a) 90 v=1 v=5 v=7 80 70 60 50 40 0 20 40 hB / hY 60 80 100 [%] Fig. 4 show the flux barrier effect on the air-gap flux density due to reaction field of different PM machines with SL and DL winding. The simulations results are obtained using finite elements method (FEM). The all machine types are investigated under the same load condition (Ieff = 35A), and the results are presented as a relative ratio of the air-gap flux densities components of the new machine design to the corresponding conventional machine with the conventional stator. As before, only the first three air-gap flux density harmonics are investigated ( Bν , FB / Bν ,Conv where, v = 1, 5, and 7). As well is shown from Fig. 4a), for the electric machine with the SL winding the 1st sub-harmonics decrease linearly with increasing of the flux-barrier depth parameter hB. It can be concluded here that a completely cut out of the yoke region st reduces the 1 sub-harmonic about 60%. On the other side, the th th other harmonics such the 5 and the 7 are positively influenced (slightly increased). Analogous, also for the electric machine with the DL winding, the flux-barriers in stator yoke region reduce the air-gap flux density sub-harmonics. Fig. 4b) st shows that for this machine type the 1 sub-harmonic completely can be suppressed by choosing a proper flux-barrier depth (hB equal to 65% of hY.). However, contrary to the SL design, here the flux-barriers slightly reduce the 5th and the 7th high harmonics. Further, also the results presented in Fig. 4c) for the new stator design with flux-barriers in the teeth region show significant improvements in the air-gap flux density harmonics. For the SL winding type, the flux-barriers st th decrease significantly the 1 and the 5 harmonics, but simultaneously increase the amplitude of the air-gap flux th density for the 7 harmonic. Therefore, as result of the positive th effect on the 7 harmonics, the new stator structure is suitable for a 14-poles machine with the SL winding. III. ANALYSIS OF DIFFERENT PM MACHINES 120 BvFB / BvConv [ % ] 100 b) 80 60 40 v=1 v=5 v=7 20 0 0 20 40 hB / hY 60 80 100 40 50 [%] 120 BvFB / BvConv [ % ] 100 TW c) FB 80 60 40 20 0 0 v=1 v=5 v=7 10 20 FB / TW 30 [%] Fig. 4: Flux-barrier effect on the air-gap flux density harmonics; a). 12-teeth/10-poles SL winding, b). 12-teeth/10-poles DL winding, c). 12-teeth/14-poles SL winding. During the following work several PM machines with SL and DL winding topology and magnetic flux-barriers in the stator yoke/teeth regions are investigated. For each machine topology illustrated in Fig. 4, also the analogous PM designs with the conventional stator core are considered as corresponding reference machines. In total there are six PM machines that are analyzed and compared. The main geometry data of the studied PM machines are resumed in Table-II. The flux barrier depth for the 12-teeth/10-poles SL and DL design are taken to be 0.95 * h Y and 0.65 * h Y, respectively, however the flux barrier width for the 12-teeth/14-poles design is taken to be 0.33 * TW. For the all machine designs the electrical and geometrical constrains are taken to be the same (UDC = 12 V, Ieff = 35Arms and volume: DOut=81mm, LStack=70mm). Further, the same stator and rotor design, the same number of turns per phase and also the same magnet material amount is considered for the all examples; the only difference on the investigated machine geometries is the stator core (with- and without flux barriers) and the winding layout (single-/ double-layer). The simulation results presented in the following are performed using finite elements (FE) method. Analogous to the previous section, the same load condition (35Arms load current) is considered. Further, for each machine topology, the 377 main machine parameters such as, the electromagnetic torque and torque ripple, inductances, flux-linkages, characteristic currents, and so on are determined and compared with the corresponding reference designs. a) Conv. Design New Stator b) Conv. Design New Stator c) New Stator Conv. Design Fig. 5: Flux-density distribution due to reaction field (Ieff=35A); a). 12-teeth/10-poles SL winding, IPM-1, b). 12-teeth/10-poles DL winding, IPM-2, c). 12-teeth/14-poles SL winding, IPM-3. Table-II: Main geometry parameters IPM-1 IPM-2 IPM-3 Outer stator diameter [mm] 81 81 81 Outer rotor diameter [mm] 48 48 48 Gap length [mm] 0.5 0.5 0.5 Magnet length [mm] 3 3 3 Magnet width [mm] 10 10 7.12 Active length [mm] 70 70 70 Turns per coil [--] 20 10 20 Parallel path [--] 2 2 2 Number of stator teeth [--] 12 12 12 Number of rotor poles [--] 10 10 14 SL DL SL Winding Type A. Flux density due to reaction field The flux-barrier effect on the air-gap flux density harmonics due to reaction field is already investigated in the previous section. According to the obtained results it can be concluded that for the all machine types the new stator structure reduce efficiency the sub-harmonics. The field lines distribution under the given load condition are presented in Fig. 5. Considering firstly the PM machine design with SL winding and also with conventional stator, at the first sight, the flux distributions it seems to be analogous with a two poles machine. This is as results of the high 1st sub-harmonic component generated from this winding type. However, using the new stator core with flux-barriers in stator yoke or teeth region, they limit the first component of the flux density to flows around one-half of the machine, and with this the sub-harmonic component is suppressed. Therefore, the flux distribution for the considered machines with SL winding and also the new stator structure is analogous with the DL machine design and conventional stator. On the other side, for the DL winding design, the flux-barriers reduce completely the sub-harmonic components, and according to Fig. 5b), the flux lines distribution with the new stator are more uniformly distributed around the air-gap. As is mentioned previously, the FSCW produce several harmonic components in the air-gap flux density of the PM machines. Except the fundamental or working harmonic component, the other harmonics rotate with different speed and also in different direction compared with the rotor synchronous speed. Therefore, due to the asynchronous effect of these harmonics, the resulting flux density components induced in the rotor fluctuate with the time. In the rotor reference frame these harmonics can be described using the following relation [24], ˆ sin ( k ⋅ ωt ± ν ⋅ θ + α ) , k = − ν ± 1 (3) B(t, θ) = ∑ ∑ B ν ,k ν ,k p ν k where, k is the order of the time harmonics generated from the v MMF space harmonic, B̂ν ,k is the time kth order and the vth spatial order magnetic flux density. “+” and “-“ denotes the positive, respectively the negative going wave. In order to show the flux-barrier effects on the flux density components induced in the rotor, below, the all exemplary machines are investigated in time domain. Under the same load current, the simulations are carried out for one mechanical rotor rotation and the flux density on the magnet surface (as is illustrated in Fig. 6) is observed with the time. Investigation point for the rotor flux density, B(t, θ) Fig. 6: Rotor investigation location during the time domain analysis. 378 Figs. 7(a) to 7(c) show the flux density results on the specified magnet location. The FFT analysis is applied to determine the time harmonics in the flux density curves. As well is shown here, the main time flux density harmonics induced in the rotor are the 6th, 12th, 18th, and 24th. From eq. (3), the 6th time harmonic is induced from the 1st space harmonic, the 12th time harmonic is induced from the 7th and the 17th, and the 24th time harmonic is induced from the 19th space harmonic. It is B [T] 0.5 Conv. Stator New Stator 0 -0.5 0 100 200 position [mech. degree] B [T] a) Conv. Stator New Stator 0.1 0.05 0 5 10 15 20 Order of time harmonics B [T] 0.5 100 200 position [mech. degree] B [T] C. Machine parameters The machine parameters plays a key role for determining various aspects of the PM machine characteristics, such as, the flux-weakening capability, torque components, fault currents and so on. The analysis of a PM machine is conveniently carried out in a d-q rotating reference frame. The steady-state equations for the voltage and the electromagnetic torque are, ud = R ⋅ id − ω Lq ⋅ iq − ωψ qm 300 0.05 5 10 15 20 Order of time harmonics 0.5 25 30 Conv. Stator New Stator 0 -0.5 0 100 200 position [mech. degree] c) 300 Conv. Stator New Stator 0.1 Te = 3 p ⎡( Ld − Lq ) ⋅ id ⋅ iq + (ψ dm ⋅ iq −ψ qm ⋅ id ) ⎤⎦ 2 ⎣ Table-III: Electromagnetic torque and torque ripples of considered machines IPM-1 T_av 5 10 15 20 Order of time harmonics 25 (5) where ψ m is the flux-linkage due to the permanent magnets, L is the machine inductance, and Te is the electromagnetic torque. Further, the dq-indexes represent the d- and q- axis components of the machine parameters. In order to examine the influence of the magnetic flux-barriers on the machine parameters, the FE investigations performed in following are carried under the same load current as before, but additionally for different current load angles. Furthermore, the saturation and also the cross-coupling effects are considered during determination of the machine parameters with the fixed permeability FE method [25, 26]. The obtained results for different load conditions are presented in Figs. 9 and 10. 0.05 0 (4) uq = R ⋅ iq + ω Ld ⋅ id + ωψ dm Conv. Stator New Stator 0.1 0 B. Electromagnetic Torque During determination of the electromagnetic torque the simulations are performed for different rotor positions and for the same load condition as before. The torque behavior vs. rotor positions (one electrical period) are presented and compared in the following Fig. 8. Additionally, the values for the average torque and torque ripples are resumed in Table-III. Analyzing the obtained results it can be concluded that for the 10-poles PM machine designs (IPM-1 and IPM-2) the flux-barrier effect represents only minor effect in the torque components, however, for the 14-poles PM machine with SL winding (IPM-3) the new stator structure increase the torque density for about 15%. Also the torque ripples are improved for this machine design. 30 0 b) B [T] 25 Conv. Stator New Stator -0.5 0 B [T] 300 important to point out that these time harmonics are mainly responsible for the rotor losses (iron core and magnets). Therefore, using the new stator design with magnetic flux-barriers, these harmonics significantly are reduced which leads to the rotor loss reduction [22, 23]. [Nm] 30 T_rippl Fig. 7: Results of time analysis for the rotor flux density due to the reaction field; a). IPM-1 machines, b). IPM-2 machines, c). IPM-3 machines. 379 [%] IPM-2 IPM-3 Conv. Stator 3.97 4.15 3.87 New Stator 4.12 4.05 4.55 Conv. Stator 11.2 10 12.25 New Stator 10.4 9.87 9.98 5 0.3 0.25 3 0.2 Conv. Stator New Stator 2 a) L [ mH ] a) T [Nm] 4 0.15 0.1 1 Ld_conv Lq_FB Lq_conv Ld_FB 0.05 0 0 60 120 180 240 300 rotor position [el. degree] 0 360 0 10 20 30 40 50 60 70 Load angle [el. degree] 80 90 5 0.3 0.25 3 0.2 Conv.… New Stator 2 b) 1 L [ mH ] b) T [Nm] 4 0.15 0.1 Ld_conv Lq_FB Lq_conv Ld_FB 0.05 0 0 60 120 180 240 300 rotor position [el. degree] 0 360 0 10 20 30 40 50 60 70 Load angle [el. degree] 80 90 80 90 5 0.3 0.25 3 0.2 Conv.… c) 2 1 L [ mH ] c) T [Nm] 4 0.15 0.1 Ld_conv Lq_FB Lq_conv Ld_FB 0.05 0 0 60 120 180 240 300 rotor position [el. degree] 0 360 0 ν ν 20 30 40 50 60 70 Fig. 9: dq-inductances vs. current load angle for Ieff =35A; a). IPM-1 machines, b). IPM-2 machines, c). IPM-3 machines. The simulation results show that, the winding inductances for the SL and DL winding are different even the number of turns per phase is taken to be the same (see Table-II). This property can be explained by analyzing their winding inductance functions. Relation (6) describe the inductance function derived according to [27, 28] which includes the synchronous plus harmonic inductance. With L1 and L2 are denoted the winding inductances for the SL and DL winding. 16 1 L1 = N 2w1 ⋅ r ⋅ l ⋅ Λ 0 ⋅ ∑ ν ξ w21 π ν ν (6) 16 1ν 2 2 L2 = 2 N w 2 ⋅ r ⋅ l ⋅ Λ 0 ⋅ ∑ ξ w 2 π 10 Load angle [el. degree] Fig. 8: Electromagnetic torque vs. rotor position; a). IPM-1 machines, b). IPM-2 machines, c). IPM-3 machines. In the above eq. (6), with r is denoted the air-gap radius, l is the machine effective length, and Λ0 is the magnetic permeance. From (6), the ratio between synchronous inductances for the SL and DL winding is 2 2 L1 1 ⎛ N w1 5ξ w1 ⎞ 1 ⎛ 20 0.966 ⎞ = ⎜ ⋅ ⎟ = ⎜ ⋅ ⎟ = 2.1 L2 2 ⎝ N w 2 5ξ w 2 ⎠ 2 ⎝ 10 0.933 ⎠ (7) Eq. (7) indicates that the SL winding has higher inductance compared with the analogous DL winding. In the FE results presented in Fig. 9, it is shown that for the conventional stator case the ratio between these inductances, depending on the 380 In above eq. (8) with n Θˆ PM the amplitude of the rotor MMF due to magnets, and n are the rotor MMF space harmonics. 14 12 Flux [ mVs ] 10 a) 8 Flux-Q, conv. Flux-Q, FB Flux-D, conv. Flux-D, FB 6 4 2 0 -2 -4 0 10 20 30 40 50 60 70 Load angle [el. degree] 80 90 14 12 b) Flux [ mVs ] 10 8 Flux-Q, conv. Flux-Q, FB Flux-D, conv. Flux-D, FB 6 4 2 0 -2 -4 0 10 20 30 40 50 60 70 Load angle [el. degree] 80 90 80 90 10 8 c) Flux [ mVs ] load condition, is between 1.5 and 1.6, and compared with relation (7) the inductance ratio is lower. The main reason for this discrepancy is on that, the relation (7) consider only the synchronous inductance, however if the slot-leakage inductance and also the saturation effect are considered, then the deviation between the FEM and the analytical models would be closer. On the other side, comparing the inductance results for the conventional- and also the new stator design, it can be seen that, for the SL winding the flux-barriers have a considerable effect on the dq-inductance results. For this winding type the flux-barriers reduce the coupling effect between the phase coils (opposite coils of one-phase) and also the 1st sub-harmonic which are the main factors that leads to the inductance reduction. Otherwise, for the DL winding design, the flux-barriers effect on the dq-inductances is minimal, even in the flux density we can see a more uniformly distribution of the flux lines around the air-gap than for the conventional stator. In contrast to the SL winding, the relative amount of the 1st sub-harmonic in the winding inductances is clearly small, and therefore the reduction of this harmonic has a negligible effect on the machine inductances. Further FE simulation results for the flux-linkages due to PM for different load conditions are given in Fig. 10. In these diagrams the two components of the flux-linkages are presented. As well is known, the d-axis component is the main PM flux-linkage component, however the q-axis component is a parasitic component which appears as results of the cross coupling effect when the saturation in the machine occurs. This can be seen also from the flux-linkage results for the SL winding where, due to high component of sub-harmonics the saturation in the machine is higher compared with the DL machine design, and with this also the q-axis flux-linkage component is higher. It is important to remember here that this parasitic component influence negatively the electromagnetic torque (please see eq. (5)). Therefore, the reduction of this component using the new stator design is an additional advantages regarding to the torque capability of the machine. On the other side, considering again the SL design, the fluxbarriers in the stator yoke region decrease the d-axis flux-linkage component for the 10-poles machine design (IPM-1), however, in contrast for the 14-poles machine (IPM-3) the new stator with flux-barriers in the stator teeth region increase the main components of the PM flux-linkage. As results, the torque density of this machine type additionally is improved. Further, comparing the flux-linkage results for the conventional stator, it can be seen that there exists a small difference between the SL and the DL design even the number of turns per phase and also the amount of the magnet material in rotor is taken to be the same. This can be validated also with the flux-linkage functions presented in (8) and (9). 4 1n ˆ ψ 1 = N w1 ⋅ r ⋅ l ⋅ Λ 0 ⋅ ∑ ξ w1 ⋅ n Θ PM p n n = p (1,3,5,..) (8) 4 1n n ˆ ψ 2 = 2 N w2 ⋅ r ⋅ l ⋅ Λ0 ⋅ ∑ ξ w2 ⋅ Θ PM p n = p (1,3,5,...) n 6 FluxQ, conv. Flux-Q, FB 4 2 0 -2 -4 0 10 20 30 40 50 60 70 Load angle [el. degree] Fig. 10: dq-PM flux-linkage vs. current load angle for Ieff =35A; a). IPM-1 machines, b). IPM-2 machines, c). IPM-3 machines. From (8), the ratio between the flux-linkage components for the SL and DL winding is 5 ψ1 N ξ 20 0.966 = w1 ⋅ 5 w1 = ⋅ = 1.036 ψ 2 2 N w2 ξ w1 2 ⋅10 0.933 (9) D. Field weakening characteristics The field weakening capability of PM machines depends on the machine parameters and particularly from the winding inductances. Generally, PM machines with concetrated windings are characterized with high winding inductance and thus with high flux weakening capability. According to [29], the characteristic current Ich is the best indicator for the 381 flux-weakening capability of PM machines, which is defined as follows 60 (10) Fig. 11 show the characterisitcs currents for the considered machines with and without flux-barriers in stator. The machine parameters given in previous section are used in (10) for determination of Ich. From the results it can be seen that the SL winding design is characterized with low characteristic curent compared with the DL winding. This is as results of high winding inductance for this winding type. Additionally, for the SL winding type the flux-barriers increase the characteristic current up to 32%, however, for the double winding his effect is negligible. Therefore, at the first point of view, regarding to the field weakening capability the SL winding design show to be a good solution compared with the DL winding, and unfortunately the new stator design decrease this capability. However, this conclusion isn’t always true because the field weakening capability depend on many parameters such as load current, saturation condition and so on. To have a clear answer regarding to this feature, in Fig. 12 the torque-speed characteristics of the considered machines are investigated for different load currents. The simulations are performed according to the previous relations (4) and (5) and under the fixed 12V DC voltage condition. Based on these results, the field weakening capability of the machines is different depending on the load currents. For the IPM-1 design with the SL winding the flux barriers improves the torque-speed characteristics at high load current, however, at low current they show an contrary effect. Further, the DL machine design at high load show analogous performances as the IPM-1 with flux barriers, and the new stator design doesn’t influence its torque-speed characteristics. However, at lower load, as results of low inductance the field weakening characteristics of this machine type are degraded. And finally for the IPM-3 design, the new stator shows a positive effect for the both load currents. Therefore, considering these results it can be concluded here that only a high d-axis inductances is not always responsible for a good field weakening capability, however, according to voltage equations given in (4) the both Ld and Lq inductance parameters are responsible for the maximal voltage and field weakening characteristics of the machine. As results of a high Lq inductance for the conventional stator design the ud voltage increase rapidly with the rotor speed, and the sum of voltage components ( uq2 + ud2 ) reach early the voltage limit and also the field weakening region. On the other side, for a specific load current, the high Ld inductance sometimes can produce an over weakening of the magnet flux that results to a linearly increase of the uq voltage with the speed in the negative region. IV. CONCLUSION The new stator design with magnetic flux-barrier in stator yoke or in tooth region is an efficiency method for reducing the air-gap flux density sub-harmonics of PM machines with FSCW. Using this new technique, the resulting additional rotor losses (permanent magnets and rotor core), and also the a) Psi_pm / Ld [Arms] 40 20 0 0 10 20 30 40 50 60 70 Load angle [el. degree] 80 90 80 Conv. Stator New Stator 60 b) Psi_pm / Ld Ld Conv. Stator New Stator 40 20 0 0 10 20 30 40 50 60 70 Load angle [el. degree] 80 90 80 Conv. Stator New Stator Psi_pm / Ld I ch = ψ dm 80 60 40 20 0 0 10 20 30 40 50 60 70 Load angle [el. degree] 80 90 Fig. 11: Characteristic current vs. current load angle for Ieff =35A; a). IPM-1 machines, b). IPM-2 machines, c). IPM-3 machines. other parasitic effect can be reduced or completely canceled. On the other side, also the other machine parameters and performances are influenced with the new stator structure. To show that, different PM machines with different pole/slot combinations, and also with the conventional and the new stator structure are consider during this work. The all exemplary machines are designed under the same electrical and geometrical constrains, and the only difference is taken to be in the stator design (conventional and the new stator with flux-barriers). The main machine parameters and performances, such as air-gap flux density characteristics, dqparameters, characteristic currents, electromagnetic torque, and the field weakening capability are investigated carefully 382 REFERENCES 8 T [Nm] 6 a) [1] New Stator, 60A Conv. Stator, 60A New Stator, 35A Conv. Stator, 35A [2] 4 [3] 2 [4] 0 0 400 8 T [Nm] speed [ rpm ] [5] New Stator, 60A Conv. Stator, 60A New Stator, 35A Conv. Stator, 35A 6 b) 800 1200 1600 2000 2400 2800 3200 [6] 4 [7] 2 [8] 0 0 400 8 T [Nm] speed [ rpm ] [9] New Stator, 60A Conv. Stator, 60A New Stator, 35A Conv. Stator, 35A 6 c) 800 1200 1600 2000 2400 2800 3200 [10] [11] 4 [12] 2 [13] 0 0 400 800 1200 1600 2000 2400 2800 3200 speed [ rpm ] [14] Fig. 12: Electromagnetic torque vs. rotor speed for different load currents; a). IPM-1 machines, b). IPM-2 machines, c). IPM-3 machines. [15] and are compared with the analogous conventional machine designs. The results obtained from this work show that the new stator design brings several advantages over the conventional design such as: Sub-harmonic reduction more than 60%. The resulting rotor losses significantly can be reduced. Torque density improvements. Especially, for the 12-teeth/14-poles design with the SL winding, the new technique shows torque increase up to 16%. High field weakening capability. The flux-barriers reduce the winding harmonic inductances. For the SL winding type, the new stator improves the field weakening capability of the machine. [16] [17] [18] [19] [20] 383 C. M. Spargo, B. C. Mecrow, J. D. Widmer, “Application of Fractional Slot Concentrated Windings to Synchronous Reluctance Machines”, IEEE International Electric Machines and Drives Conference, IEMDC2013, pp.618-625, Chicago, USA, May 12-15, 2013. Z. Azar, Z. Q., “Investigation of Electromagnetic Performance of Salient-Pole Synchronous Reluctance Machines Having Different Concentrated Winding Connections”, IEEE International Electric Machines and Drives Conference, IEMDC2013, pp.359-366, Chicago, USA, May 12-15, 2013. A. S. Abdel-Khalik, S. Ahmed, “Performance Evaluation of a FivePhase Modular Winding Induction Machine”, IEEE Transactions on Industrial Electronics, Vol. 59, No. 6, pp. 2654 – 2669, June 2012. O. Moros, Gerling, D., “New 30-Teeth / 14-Poles Concentrated Winding for Use in Induction Machines”, 4. Tagung Elektrische Antriebstechnologie für Hybrid- und Elektrofahrzeuge, Haus der Technik, Vol. 131, pp.352-361, 26.-27. November 2013, Muenchen, Germany. G. Heins, D. Ionel, M. Thiele, “Winding Factors and Magnetic Fields in Permanent Magnet Brushless Machines with Concentrated Windings and Modular Stator Cores”; Energy Conversion Congress and Exposition (ECCE), pp. 5048 – 5055, 15.-19. September 2013. A.M. El-Refaie, "Fractional-Slot Concentrated-Windings Synchronous Permanent Magnet Machines: Opportunities and Challenges," IEEE Transactions on Industrial Electronics, Vol.57, No.1, pp.107-121, Jan. 2010. J. Wang, K. Atallah, Z. Q. Zhu and D. Howe, “Modular Three-Phase Permanent-Magnet Brushless Machines for In-Wheel Applications”, IEEE Transactions on Vehicular Technology, Vol. 57, No. 5, pp. 27142720, September 2008. J. Li, D. W. Choi, D. H. Son, Y. H. Cho, “Effects of MMF Harmonics on Rotor Eddy-Current Losses for Inner-Rotor Fractional Slot Axial Flux Permanent Magnet Synchronous Machines”, IEEE Transactions on Magnetics, Vol. 48, No. 2, pp. 839-842, February 2012. K. Yamazaki, Y. Fukushima, “Effect of Eddy-Current Loss Reduction by Magnet Segmentation in Synchronous Motors with Concentrated Windings ”, IEEE Transactions on Industry Applications, Vol. 47, No. 2, pp. 779-788, March/April 2011. N. Bianchi, E. Fornasiero, “Index of rotor losses in three-phase fractional slot permanent magnet machines”, Electric Power Applications, IET, vol. 3, No. 5, September 2009. J. Wang, Zh. P. Xia, D. Howe, S. A. Long, “Vibration Characteristics of Modular Permanent Magnet Brushless AC Machines”, IEEE IAS Annual Meeting, 2006, Tampa, Florida, USA. G. Dajaku, D. Gerling, “The Influence of Permeance Effect on the Magnetic Radial Forces of Permanent Magnet Synchronous Machines”, IEEE Transactions on Magnetics, Vol. 49, No. 6, pp. 2953-2966, June 2013. J. Krotsch, B. Piepenbreier, “Radial Forces in External Rotor Permanent Magnet Synchronous Motors with Non-Overlapping Windings ”, IEEE Transactions on Industrial Electronics, Vol. 59, No. 5, pp. 2267-2276, May 2012. M. V. Cistelecan, F. J. T. E. Ferreira, “Three phase tooth-concentrated multiple-layer fractional windings with low space harmonic content”, IEEE on Energy Conversion Congress and Exposition (ECCE) 2010. E. Farnasiero, L. Alberti, N. Bianchi and S. Bolognani,“Considerations on selecting fractional–slot windings”, Energy Conversion Congress and Exposition (ECCE), 2010 IEEE, pp. 1376-1383, 12-16 Sept. 2010. K. Ito, K. Naka, M. Nakano, and M. Kobayashi, “Electric machine,” US Patent US7 605 514, 20 Oct 2009. M. Cistelecan, F. F. Ferreira, and M. Popescu, “Three-phase toothconcentrated interspersed windings with low space harmonic content,” 19-th International Conference on Electrical Machines (ICEM’2010), 02.-05. September 2010, Rome, Italy. G. Dajaku, D. Gerling, “Eddy Current Loss Minimization in Rotor Magnets of PM Machines using High-Efficiency 12-teeth/10-poles Winding Topology”, International Conference on Electrical Machines and Systems (ICEMS-2011), Beijing, China ,August 20-23, 2011. G. Dajaku, D. Gerling, “A Novel 24-Slots/10-Poles Winding Topology for Electric Machines”, International Electric Machines and Drives Conference (IEMDC-2011), Niagara Falls (Ontario), Kanada, May 1518, 2011, pp. 65-70. Reddy, P.B.; Kum-Kang Huh; El-Refaie, A., "Effect of stator shifting on harmonic cancellation and flux weakening performance of interior [21] [22] [23] [24] [25] [26] [27] [28] [29] [30] PM machines equipped with fractional-slot concentrated windings for hybrid traction applications," Energy Conversion Congress and Exposition (ECCE), 2012 IEEE , Vol., No., pp.525-533, 15-20 Sept. 2012. G. Dajaku, D. Gerling, “A Novel Tooth Concentrated Winding with low Space Harmonic Content”, International Electric Machines and Drives Conference (IEMDC-2013), Chicago, IL, USA, May 12-15, 2013. G. Dajaku, D. Gerling, “A Novel 12-Teeth/10-Poles PM Machine with Flux Barriers in Stator Yoke”, 20-th International Conference on Electrical Machines (ICEM’2012), 02.-05. September 2012, Marseille, France. G. Dajaku, D. Gerling, “Low Costs and High-Efficiency Electric Machines”, 2nd International Electric Drives Production Conference 2012 (EDPC-2012), 16.-17. October 2012, Erlangen-Nürnberg, Germany. M. Nakano, H. Kometani, M. Kawamura, “A Study on Eddy-Current Losses in Rotors of Surface Permanent-Magnet Synchronous Machines”, IEEE Transactions on Industrial Applications, Vol. 42, No.2, pp.429-435, March. 2006. Z. Jibin, L. Weiyan, “Analytical modelling Finite Element Calculation of the Saturation DQ-Axes Inductance for a Direct Drive PM Synchronous Motor Considering Cross-Magnetization”, The Fifth International Conference on Power Electronics and Drive Systems, 2003, (PEDS 2003), pp. 677–681, 17-20 Nov. 2003. N. Bianchi, S Bolognani, “Magnetic Models of Saturated Interior Permanent Magnet Motors based on Finite Element Analysis”,The Thirty-Third Industry Applications Conference, 1998 (IAS Annual Meeting), 12-15 Oct. 1998. D. Ishak, Z. Q. Zhu, and D. Howe, “Comparison of PM Brushless Motors, Havong Either All Teeth or Alternate Teeth Wound”, IEEE Transactions on Energy Conversion,Vol. 21, No. 1, pp. 95-103, March 2006. R. Dutta, L. Chong, M. F. Rahman, “Winding Inductances of an Interior Permanent Magnet (IPM) Machine With Fractional Slot Concentrated Winding”, IEEE Transactions on Magnetics, Vol. 48, No. 12, pp. 4842-4849, December 2012. A. M. El-Refaie, T. M. Jahns, “Optimal Flux Weakening in Surface PM Machines using Concentrated Windings” The 39th Industry Applications Conference 2004, IAS Annual Meeting, pp. 1038-1047. Z. Q. Zhu, "Fractional slot permanent magnet brushless machines and drives for electric and hybrid propulsion systems", COMPEL: The International Journal for Computation and Mathematics in Electrical and Electronic Engineering, Vol. 30 Iss: 1, pp.9 – 31, 2011. V. BIOGRAPHIES Gurakuq Dajaku was born in 1974 in Skenderaj, Kosova. He received the diploma degree in electrical engineering from the University of Prishtina, Kosova, in 1997 and the Ph.D. degree from the Universitaet der Bundeswehr Muenchen, Munich, Germany, in 2006. Since 2007 he has been a Senior Scientist with FEAAM GmbH, an engineering company in the field of electric drives. Since 2008 and 2010 he has been a Lecturer at the Universitaet der Bundeswehr Muenchen, Germany, and the University of Prishtina, Kosova, respectively. His research interest is in the field of electrical machines and drives. He has published numerous technical papers in different IEEE journals and conferences and has several international patents and patent pending applications. Dr. Dajaku received the Rheinmetall Foundation Award 2006 and the ITIS (Institute for Technical Intelligent Systems) Research Award 2006. Dieter Gerling was born in 1961 in Menden/Sauerland, Germany. He received the diploma and Ph.D. degrees in electrical engineering from the Technical University of Aachen, Aachen, Germany, in 1986 and 1992, respectively. From 1986 to 1999, he was with Philips Research Laboratories, Aachen, as Research Scientist and later as Senior Scientist. In 1999, he joined Robert Bosch GmbH, Bühl, Germany, as Director. Since 2001, he has been a Full Professor at the Universitaet der Bundeswehr Muenchen, Munich, Germany (http://www.unibw.de/EAA/). 384 Powered by TCPDF (www.tcpdf.org)