5.1 Shell-and-Tube Heat Exchangers

advertisement

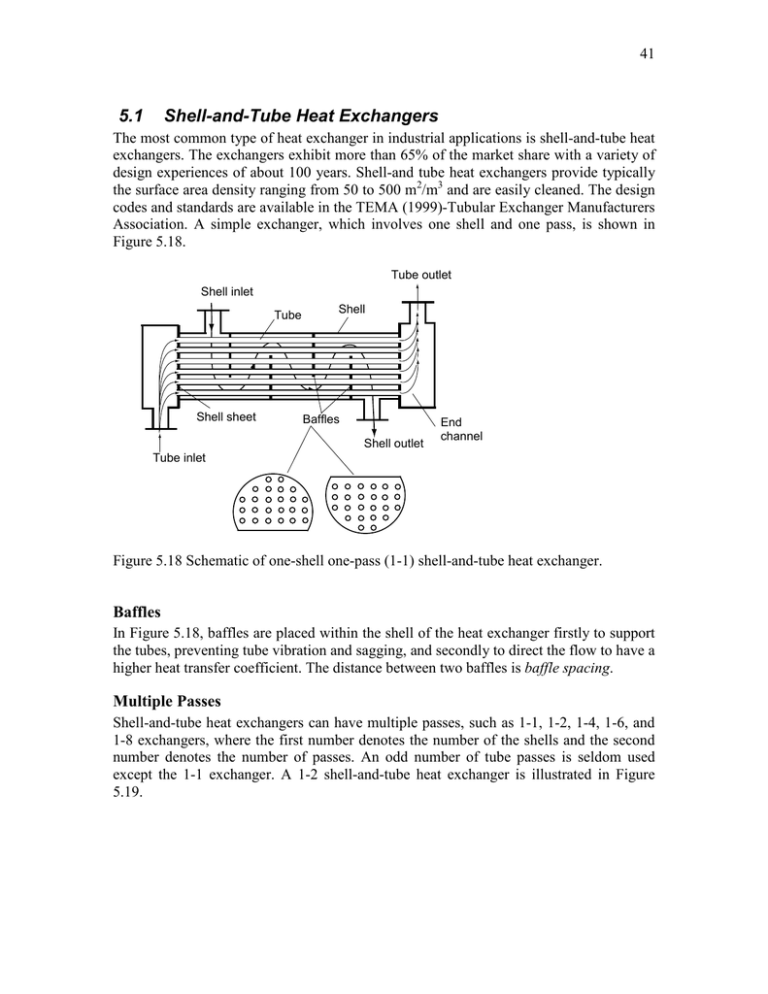

41 5.1 Shell-and-Tube Heat Exchangers The most common type of heat exchanger in industrial applications is shell-and-tube heat exchangers. The exchangers exhibit more than 65% of the market share with a variety of design experiences of about 100 years. Shell-and tube heat exchangers provide typically the surface area density ranging from 50 to 500 m2/m3 and are easily cleaned. The design codes and standards are available in the TEMA (1999)-Tubular Exchanger Manufacturers Association. A simple exchanger, which involves one shell and one pass, is shown in Figure 5.18. Tube outlet Shell inlet Tube Shell sheet Shell Baffles Shell outlet End channel Tube inlet Figure 5.18 Schematic of one-shell one-pass (1-1) shell-and-tube heat exchanger. Baffles In Figure 5.18, baffles are placed within the shell of the heat exchanger firstly to support the tubes, preventing tube vibration and sagging, and secondly to direct the flow to have a higher heat transfer coefficient. The distance between two baffles is baffle spacing. Multiple Passes Shell-and-tube heat exchangers can have multiple passes, such as 1-1, 1-2, 1-4, 1-6, and 1-8 exchangers, where the first number denotes the number of the shells and the second number denotes the number of passes. An odd number of tube passes is seldom used except the 1-1 exchanger. A 1-2 shell-and-tube heat exchanger is illustrated in Figure 5.19. 42 Tube outlet Shell inlet Tube Pass partition Shell End channel Baffles Shell outlet Tube inlet Figure 5.19 Schematic of one-shell two-pass (1-2) shell-and-tube heat exchanger. Lt B Ds Figure 5.20 Dimensions of 1-1 shell-and-tube heat exchanger Dimensions of Shell-and-Tube Heat Exchanger Some of the following dimensions are pictured in Figure 5.20. L = tube length N t = number of tube N p = number of pass Ds = Shell inside diameter N b = number of baffle B = baffle spacing The baffle spacing is obtained B= Lt Nb +1 (5.128) 43 Shell-Side Tube Layout Figure 5.21 shows a cross section of both a square and triangular pitch layouts. The tube pitch Pt and the clearance Ct between adjacent tubes are both defined. Equation (5.30) of the equivalent diameter is rewritten here for convenience De = 4 Ac Pheated (5.129) From Figure 5.21, the equivalent diameter for the square pitch layout is De = ( 4 Pt − πd o 4 πd o 2 2 ) (5.130a) From Figure 5.21, the equivalent diameter for the triangular pitch layout is 3Pt 2 πd o 2 4 − 4 8 De = πd o 2 (5.130b) The cross flow area of the shell Ac is defined as Ac = Ds C t B PT (5.131) do do di di Flow Ct Ct Pt (a) Pt (b) Figure 5.21 (a) Square-pitch layout, (b) triangular-pitch layout. The diameter ratio dr is defined by dr = do di (5.132) Some diameter ratios for nominal pipe sizes are illustrated in Table C.6 in Appendix C. The tube pitch ratio Pr is defined by 44 Pr = Pt do (5.133) The tube clearance Ct is obtained from Figure 5.21. Ct = Pt − d o (5.134) The number of tube Nt can be predicted in fair approximation with the shell inside diameter Ds. N t = (CTP ) πDs2 4 (5.135) ShadeArea where CTP is the tube count constant that accounts for the incomplete coverage of the shell diameter by the tubes, due to necessary clearance between the shell and the outer tube circle and tube omissions due to tube pass lanes for multiple pass design [1]. CTP = 0.93 CTP = 0.9 CTP = 0.85 for one-pass exchanger for two-pass exchanger for three-pass exchanger ShadeArea = CL ⋅ Pt 2 (5.136) (5.137) where CL is the tube layout constant. CL = 1 for square-pitch layout CL = sin(60°) = 0.866 for triangular-pitch layout (5.138) Plugging Equation (5.137) into (5.135) gives π CTP Ds2 2 = 4 CL Pt 4 CL Pr2 d o2 (5.139) Table 5.1 Summary of shell-and-tube heat exchangers Description Equation q = m& 1c p1 (T1i − T1o ) Basic Equations q = m& 2 c p 2 (T2o − T2i ) (5.140) Nt = π CTP Ds2 Heat transfer areas of the inner and outer surfaces of an inner pipe Ai = π ⋅ d i ⋅ N t ⋅ L Ao = π ⋅ d o ⋅ N t ⋅ L (5.141) (5.142a) (5.142b) 45 Overall Heat Transfer Coefficient Uo = 1 Ao d ln o d 1 1 + i + hi Ai ho Ao 2πkL (5.143) Tube side Reynolds number ρu m d i m& d i = µ Ac µ Re D = Ac = (5.144) πd i2 N t (5.144a) 4 Np 1 Laminar flow (Re < 2300) hd d Re Pr 3 µ Nu D = i = 1.86 i kf L µ s 0.14 (5.145) 0.48 < Pr < 16,700 0.0044 < (µ µ s ) < 9.75 Use Nu D = 3.66 if Nu D < 3.66 Turbulent flow (Re > 2300) Nu D = hd i ( f / 2)(Re D − 1000) Pr = 12 kf 1 + 12.7( f / 2 ) Pr 2 3 − 1 ( ) (5.146) 3000 < Re D < 5 × 10 6 [4] 0.5 ≤ Pr ≤ 2000 Friction factor Shell side Square pitch layout (Figure 5.21) Triangular pitch layout (Figure 5.21) Cross flow area Reynolds number f = (1.58 ln (Re D ) − 3.28) ( 4 Pt − πd o 4 De = πd o 2 2 ) 3Pt 2 πd o 2 − 4 4 8 De = πd o 2 DCB Ac = s t Pt ρu D m& De Re D = m e = µ Ac µ −2 (5.147) (5.148a) (5.148b) (5.149) (5.150) 46 Nusselt number µ h D Nu = o e = 0.36 Re 0.55 Pr 1 3 kf µs 6 2000 <Re < 1 x 10 0.14 (5.151) ε-NTU Method Heat transfer unit (NTU) NTU = Capacity ratio Cr = (5.152) U o Ao (m& c p )min (m& c ) (m& c ) p min (5.153) p max Effectiveness One shell (2, 4,.. passes) ε = 21 + C r + 1 + C r 2 ( [ ( ) ] ) 1 − exp[− NTU (1 + C ) ] (5.154) 12 1 + exp − NTU 1 1 + C r2 12 2 12 r 1 NTU 1 = NTU N p Heat transfer unit (NTU) ( where E = ) E −1 ln E +1 2 ε − (1 + C r ) NTU = − 1 + C r 2 −1 2 (5.155) (1 + C ) 2 12 r Effectiveness Heat transfer rate ε= q qmax = (m& c )(T − T ) = (m& c )(T (m& c ) (T − T ) (m& c ) (T 1 p1 p min 1i 1i 1o 2i 2 p2 p min 2o 1i − T2i ) − T2i ) (5.156) q = ε (m& c p )min (T1i − T2i ) (5.157) f ⋅ Lt 1 ∆P = 4 + 1 N p ρ ⋅ v 2 2 di (5.158) Tube Side Pressure Drop Pressure drop Laminar flow Turbulent flow Shell Side Pressure Drop f = 16 Re D f = (1.58 ln (Re D ) − 3.28) −2 (5.159) (5.160) 47 Ds (N b + 1) 1 ρ ⋅ v 2 De 2 f = exp(0.576 − 0.19 ln (Re s )) ∆P = f (5.161) (5.162) 48 Example 5.2 Miniature Shell-and-Tube Heat Exchanger A miniature shell-and-tube heat exchanger is designed to cool engine oil in an engine with the engine coolant (50% ethylene glycol). The engine oil at a flow rate of 0.23 kg/s enters the exchanger at 120°C and leaves at 115°C. The 50% ethylene glycol at a rate of 0.47 kg/s enters at 90°C. The tube material is Cr alloy (kw = 42.7 W/mK). Fouling factors of 0.176x10-3 m2K/W for engine oil and 0.353x10-3 m2K/W for 50% ethylene glycol are specified. Route the engine oil through the tubes. The permissible maximum pressure drop on each side is 10 kPa. The volume of the exchanger is required to be minimized. Since the exchanger is custom designed, the tube size can be smaller than NPS 1/8 (DN 6 mm) that is the smallest size in Table C.6 in Appendix C, wherein the tube pitch ratio of 1.25 and the diameter ratio of 1.3 can be applied. Design the shell-and-tube heat exchanger. Figure E5.2.1 Shell and tube heat exchanger MathCAD format solution: Design concept is to develop a MathCAD modeling for a miniature shell-and-tube heat exchanger and then seek the solution by iterating the calculations by varying the parameters to satisfy the design requirements. It is reminded that the design requirements are the engine oil outlet temperature less than 115°C and the pressure drop less than 10 kPa in each side of the fluids. The properties of engine oil and ethylene glycol are obtained using the average temperatures from Table C.5 in Appendix C. Toil := ( 120°C + 115°C) 2 = 117.5⋅ °C Tcool := ( 90°C + 100°C) 2 = 95⋅ °C (E5.2.1) 49 Engine oil (subscript 1)-tube side kg ρ1 := 828 3 m cp1 := 2307 50% Ethylene glycol (subscript 2)-shell side kg ρ2 := 1020 3 m J cp2 := 3650 kg⋅ K W k1 := 0.135 m⋅ K (E5.2.2) J kg⋅ K W k2 := 0.442 m⋅ K − 2 N⋅s µ 1 := 1.027⋅ 10 2 − 2 N⋅ s µ 2 := 0.08⋅ 10 2 m Pr1 := 175 m Pr2 := 6.6 The thermal conductivity for the tube material (Chromium alloy) is given W kw := 42.7 m⋅ K (E5.2.3) Given information: The inlet temperatures are given as T1i := 120°C T2i := 90°C (E5.2.4) The mass flow rates are given as mdot1 := 0.23 kg mdot2 := 0.47 s kg s (E.5.2.5) The fouling factors for engine oil and 50% ethylene glycol are given as 2 − 3 m ⋅K Rfi := 0.176⋅ 10 W 2 − 3 m ⋅K Rfo := 0.353⋅ 10 W (E5.2.6) Design requirement: The engine oil outlet temperature must be less than 115°C. T1o ≤ 115°C (E5.2.7) The pressure drop on each side must be ∆P ≤ 10kPa (E5.2.8) 50 Design parameters to be sought by iterations Initially, estimate the following boxed parameters and then iterate the calculations with different values toward the design requirements. Ds := 2.0in Shell inside diameter Lt := 15in Tube length d o := 1 8 in Ds = 50.8mm Lt = 381mm Tube outside diameter (E5.2.9) (E5.2.10) do = 3.175⋅ mm (E5.2.11) The diameter ratio (dr = do/di) is given as suggested in the problem description. d r := 1.3 di := 1 ⋅d dr o di = 2.442⋅ mm (E5.2.12) The tube pitch ratio (Pr = Pt/do) is given as suggested in the problem description. Pr := 1.25 (E5.2.13) The tube pitch is then obtained from Equation (5.133). Pt := Pr⋅ do (E5.2.14) The baffle spacing is assumed and may be iterated, and the baffle number from Equation (5.128) is defined. B := 8 8 in Lt Nb := −1 B B = 25.4mm (E5.2.15) Nb = 14 (E5.2.16) The number of passes is defined by Np := 1 (E5.2.17) The tube clearance Ct is obtained from Figure 5.21 as Ct := Pt − do Ct = 0.794⋅ mm (E5.2.18) 51 From Equation (5.136), the tube count calculation constants (CTP) up to three-passes are given CTP := 0.93 if Np 1 0.9 if Np 2 0.85 otherwise (E5.2.19) From Equation (5.138), the tube layout constant (CL) for a triangular-pitch layout is given by CL := 0.866 (E5.2.20) The number of tubes Nt is estimated using Equation (5.139) and rounded off in practice. Note that the number of tubes in the shell inside diameter defined earlier indicates the compactness of a miniature exchanger. A 253-tube exchanger in a 2.25-inch shell outside diameter is commercially available for a 2-inch shell diameter. D π 2 CTP s Ntube ( Ds , d o , Pr) := ⋅ ⋅ 4 CL 2 P ⋅d r ( ( ( ) Ntube Ds , d o , Pr = 138.189 2 o (E5.2.21) )) Nt := round Ntube Ds , d o , Pr Nt = 138 (E5.2.22) Tube side (Engine oil) The crossflow area, velocity and Reynolds number are defined as 2 A c1 := v 1 := π ⋅ di 4 ⋅ Nt Np mdot1 ρ1⋅ A c1 Re1 := ρ1⋅ v 1⋅ d i µ1 −4 2 A c1 = 6.465 × 10 m (E5.2.23) v 1 = 0.43 m s (E5.2.24) Re1 = 84.603 (E5.2.25) The Reynolds number indicates very laminar flow. The velocity in the tubes appears acceptable when considering a reasonable range of 0.5 – 1.0 m/s in Table 5.4 for the engine oil. 52 The friction factor is determined automatically whether it is either laminar or turbulent using the following program as ( ) f ReD := (1.58⋅ ln(ReD) − 3.28)− 2 16 ReD if ReD > 2300 otherwise (E5.2.26) The Nusselt number for turbulent or laminar flow is defined using Equations (5.145) and (5.146) with assuming that µ changes moderately with temperature. The convection heat transfer coefficient is then obtained. ( ) NuD Dh , Lt , ReD , Pr := f ( ReD) ⋅ 2 (ReD − 1000)⋅ Pr 2 f Re ( ) D ⋅ Pr 3 − 1 1 + 12.7⋅ 2 if ReD > 2300 0.5 1 Dh ⋅ ReD⋅ Pr 1.86⋅ Lt 3 otherwise (E5.2.27) ( ) Nu1 := NuD d i , Lt , Re1 , Pr1 h 1 := Nu1 ⋅ k1 di Nu1 = 8.484 (E5.2.28) h 1 = 468.972⋅ W 2 m ⋅K (E5.2.29) Shell side (50% ethylene glycol) The free-flow area is obtained using Equation (5.131) and the velocity in the shell is also calculated A c2 := v 2 := Ds ⋅ Ct ⋅ B Pt mdot2 ρ2⋅ A c2 −4 2 A c2 = 2.581 × 10 m (E5.2.30) v 2 = 1.786 m s (E5.2.31) 53 The velocity of 1.786 m/s in the shell is acceptable because the reasonable range of 1.2 – 2.4 m/s for the similar fluid shows in Table 5.4. The equivalent diameter for a triangular pitch is given in Equation (5.148b) as P 2⋅ 3 π ⋅ d 2 o t − 8 4 De := 4⋅ π ⋅d o 2 Re2 := De = 2.295⋅ mm (E5.2.32) ρ2⋅ v 2⋅ De 3 Re2 = 5.225 × 10 µ2 (E5.2.33) The Nusselt number is given in Equation (5.152) and the heat transfer coefficient is obtained. 1 0.55 Nu2 := 0.36⋅ Re2 h 2 := ⋅ Pr2 3 (E5.2.34) Nu2 ⋅ k2 4 h 2 = 1.442 × 10 ⋅ De W 2 m ⋅K (E5.2.35) The total heat transfer areas for both fluids are obtained as 2 A i := π ⋅ d i⋅ Lt ⋅ Nt A i = 0.403m A o := π ⋅ d o ⋅ Lt ⋅ Nt A o = 0.524⋅ m (E5.2.36) 2 (E5.2.37) The overall heat transfer coefficient is calculated using Equation (5.143) with the fouling factors as 1 Ao Uo := 1 h 1⋅ A i + Rfi Ai do d i + Rfo + W Uo = 209.677⋅ 2 m ⋅K ln + 2⋅ π ⋅ kw⋅ Lt Ao 1 h 2⋅ A o (E5.2.38) 54 ε -NTU method The heat capacities for both fluids are defined and then the minimum and maximum heat capacities are obtained using the MathCAD built-in functions as W C1 = 530.61⋅ K C1 := mdot1⋅ cp1 3 W C2 = 1.716 × 10 ⋅ K C2 := mdot2⋅ cp2 ( (E5.2.39) ) ( Cmin := min C1 , C2 (E5.2.40) ) Cmax := max C1 , C2 (E5.2.41) The heat capacity ratio is defined as Cmin Cr := Cmax Cr = 0.309 (E5.2.42) The number of transfer unit is defined as NTU := Uo ⋅ A o NTU = 0.207 Cmin (E5.2.43) The effectiveness for shell-and-tube heat exchanger is give using Equation (5.154) as NTU NTU1 := Np Since (E5.2.44a) 0.5 2 0.5 1 + exp−NTU ⋅ 1 + C 1 r 2 ε hx := 2⋅ 1 + Cr + 1 + Cr ⋅ 0.5 2 1 − exp−NTU1 ⋅ 1 + Cr −1 ε hx = 0.182 (E5.2.44b) Using Equation (5.156), the effectiveness is expressed as ε hx ( ) q C1⋅ T1i − T1o q max Cmin⋅ T1i − T2i ( ) ( ) C2⋅ T2o − T2i ( ) Cmin⋅ T1i − T2i (E5.2.45) The outlet temperatures are rewritten for comparison with the outlet temperatures. 55 T1i = 120⋅ °C T2i = 90⋅ °C T1o := T1i − ε hx⋅ Cmin C1 ( ) ⋅ T1i − T2i T1o = 114.544°C ⋅ (E5.2.46) Cmin T2o := T2i + ε hx⋅ ⋅ T1i − T2i C2 ( ) T2o = 91.687°C ⋅ (E5.2.47) The engine oil outlet temperature of 114.544°C is close enough to the requirement of 105°C. The heat transfer rate is obtained ( ) 3 q := ε hx⋅ Cmin⋅ T1i − T2i q = 2.895 × 10 W (E5.2.48) The pressure drops for both fluids are obtained using Equations (5.158) and (5.161) as f ( Re1) ⋅ Lt ∆P 1 := 4⋅ di 1 2 + 1 ⋅ Np ⋅ ⋅ ρ1⋅ v 1 2 (E5.2.49) Ds 1 2 ∆P 2 := f Re2 ⋅ Nb + 1 ⋅ ⋅ ρ2⋅ v 2 De 2 ( ) ( ∆P 1 = 9.325⋅ kPa ) ∆P 2 = 5.141⋅ kPa (E5.2.50) Both the pressure drops calculated are less than the requirement of 10 kPa. The iteration between Equations (E5.2.9) and (E5.2.46) is terminated. The surface density β for the engine oil side is obtained using the relationship of the heat transfer area over the volume of the exchanger. β 1 := Ao π ⋅ D 2 s 4 ⋅ Lt 2 β 1 = 679.134⋅ m 3 m (E5.2.51) Summary of the design of the miniature shell-and-tube heat exchanger Given information T1i = 120⋅ °C engine oil inlet temperature T2i = 90⋅ °C 50% ethylene glycol inlet temperature kg 56 mdot1 = 0.23 kg mdot2 = 0.47 kg mass flow rate of engine oil s mass flow rate of 50% ethylene glycol s −4 Rfi = 1.76 × 10 2 K ⋅m ⋅ −4 Rfo = 3.53 × 10 fouling factor of engine oil W 2 K ⋅m ⋅ fouling factor of 50% ethylene glycol W Requirements for the exchanger T1o ≤ 115°C Engine outlet temperature ∆P 1 ≤ 10kPa Pressure drop on both sides Design obtained Np = 1 number of passes Ds = 50.8⋅ mm shell inside diameter d o = 3.175⋅ mm tube outer diameter d i = 2.442⋅ mm tube inner diameter Lt = 381⋅ mm tube length Nt = 138 number of tube Ct = 0.794⋅ mm tube clearance B = 25.4⋅ mm baffle spacing Nb = 14 number of baffle T1o = 114.544°C ⋅ engine oil outlet temperature T2o = 91.687⋅ °C 50% ethylene glycol outlet temperature q = 2.895⋅ kW heat transfer rate 2 β 1 = 679⋅ m surface density 3 m ∆P 1 = 9.325⋅ kPa pressure drop for engine oil Ds = 2 in Lt = 15in B = 1 in 57 ∆P 2 = 5.141⋅ kPa pressure drop for 50% ethylene glycol The design satisfies the requirements. Problems (corrected) Shell-and-Tube Heat Exchanger 5.3 A miniature shell-and-tube heat exchanger is designed to cool glycerin with cold water. The glycerin at a flow rate of 0.25 kg/s enters the exchanger at 60°C and leaves at 50°C. The water at a rate of 0.54 kg/s enters at 18°C, which is shown in Figure P5.3. The tube material is Cr alloy (kw = 60.5 W/mK). Fouling factors of 0.253x10-3 m2K/W for water and 0.335x10-3 m2K/W for glycerin are specified. Route the glycerin through the tubes. The permissible maximum pressure drop on each side is 30 kPa. The volume of the exchanger is required to be minimized. Since the exchanger is custom designed, the tube size may be smaller than NPS 1/8 (DN 6 mm) that is the smallest size in Table C.6 in Appendix C, wherein the tube pitch ratio of 1.25 and the diameter ratio of 1.3 can be applied. Design the shell-and-tube heat exchanger. Figure P5.3 Shell-and tube heat exchanger