Heavy Hex Nuts, ASTM A194 2H, Hot Dip Galvanized

advertisement

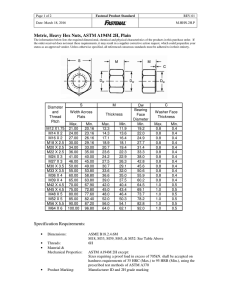

Page 1 of 2 REV-05 Fastenal Product Standard Date: July 14, 2016 HHN.2H.HDG Heavy Hex Nuts, ASTM A194 2H, Hot Dip Galvanized The information below lists the required dimensional, chemical and physical characteristics of the products in this purchase order. If the order received does not meet these requirements, it may result in a supplier corrective action request, which could jeopardize your status as an approved vendor. Unless otherwise specified, all referenced consensus standards must be adhered to in their entirety. Nominal Size 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1 1/8 1 1/4 1 3/8 1 1/2 1 5/8 1 3/4 1 7/8 2 2 1/4 2 1/2 2 3/4 3 3 1/4 3 1/2 3 3/4 4 F H Width Across Flats Thickness Max. Min. Max. .500 .488 .250 .562 .546 .314 .688 .669 .377 .750 .728 .441 .875 .850 .504 .938 .909 .568 1.062 1.031 .631 1.250 1.212 .758 1.438 1.394 .885 1.625 1.575 1.012 1.812 1.756 1.139 2.000 1.938 1.251 2.188 2.119 1.378 2.375 2.300 1.505 2.562 2.481 1.632 2.750 2.662 1.759 2.938 2.844 1.886 3.125 3.025 2.013 3.500 3.388 2.251 3.875 3.750 2.505 4.250 4.112 2.759 4.625 4.475 3.013 5.000 4.838 3.252 5.375 5.200 3.506 5.750 5.562 3.760 6.125 5.925 4.014 Dimensions above are prior to coating Min. .218 .280 .341 .403 .464 .526 .587 .710 .833 .956 1.079 1.187 1.310 1.433 1.556 1.679 1.802 1.925 2.155 2.401 2.647 2.893 3.124 3.370 3.616 3.862 Page 2 of 2 Fastenal Product Standard Date: July 14, 2016 REV-05 HHN.2H.HDG Specification Requirements: • • Dimensions: Material & Mechanical Properties: • Thread Requirements: • Finish: • Product Marking: • Material Test Reports: ASME B18.2.2 Grade 2H of ASTM A194/A194M. Sizes larger than 1-1/4” nominal diameter shall be accepted if meeting the hardness requirement of 35 HRC (Max.) to 95 HRB (Min.), using the prescribed test method of ASTM A370. Thread dimensions and oversize tapping allowance per ASTM A563. Hot dip galvanize per ASTM F2329. Must meet supplemental requirement S1 and S2 per ASTM A563. Test results to verify the effectiveness of the lubricant shall be provided using SAE J174 using hot dip galvanized A325 to a minimum clamp load of 84,000 PSI. The maximum allowable torque tension K value shall be 0.18. Exception: Test washers may be electroplated. Manufacturer ID and 2HZN (or 2HBZN when manufactured from bar stock) The MTR must have documented lot traceability, dimensional results, full chemical test results and full mechanical test results to the specification(s) above. In addition, the MTR shall be in full compliance with Fastenal’s MTR Requirements.