Results and sustainability analysis / Best practice guidelines Part A

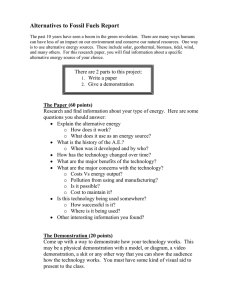

advertisement