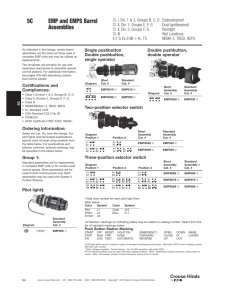

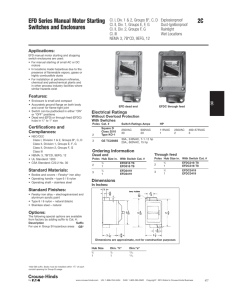

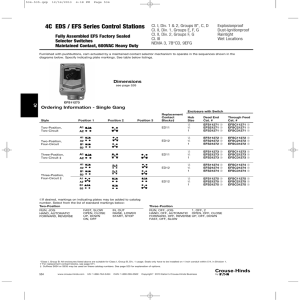

Brochure

advertisement