CASE STUDY

Operator Maintains 5-ft Drilling Target Window

for 6,890-ft Horizontal Well Offshore Australia

Real-time steering delivers optimal exposure to good-quality reservoir sands

CHALLENGE

Drill within narrow target zone in a challenging horizontal well

Minimize attic oil and avoid the oil/water

contact (OWC) in a horizontal well up to

6,890 ft [2,100 m] long by steering and

maintaining the wellbore 5–10 ft [1.5–3 m]

below the top of the reservoir.

An operator in Australia wanted to maximize exposure to good-quality sands in thinner oil columns

and drill longer horizontal trajectories, up to 6,890 ft [2,100 m], offshore Australia. It set a target

window of drilling 5–10-ft [1.5–3-m] TVD below the reservoir top to minimize attic oil production and

avoid the OWC. The wellbore would have to be maintained within the target window for the length of

the 6,890-ft [2,100-m] well section. However, the lower net sand and interbedded nature of the field

presented reservoir steering challenges.

SOLUTION

Use the GeoSphere* reservoir

mapping-while-drilling service to drill

a 6,890-ft [2,100-m] horizontal well

in narrow target window.

RESULTS

■■

■■

■■

Optimized the steering window on the

basis of mapping-while-drilling information

used to evaluate the oil column.

Maximized exposure to good-quality

reservoir sands, avoided the OWC, and

minimized attic oil by drilling in the

target window.

Determined that the layers dipped 3°–5°.

Use real-time mapping to find good-quality reservoir sands and drill on target

The operator selected the GeoSphere reservoir mapping-while-drilling service, which extends

the depth of investigation to more than 100 ft [30 m] and provides highly detailed information for

subsurface reservoir layers and fluid contacts. Using deep, directional electromagnetic measurements,

the service maps reservoirs, enabling operators to adjust drilling plans and drill on target in complex

downhole environments.

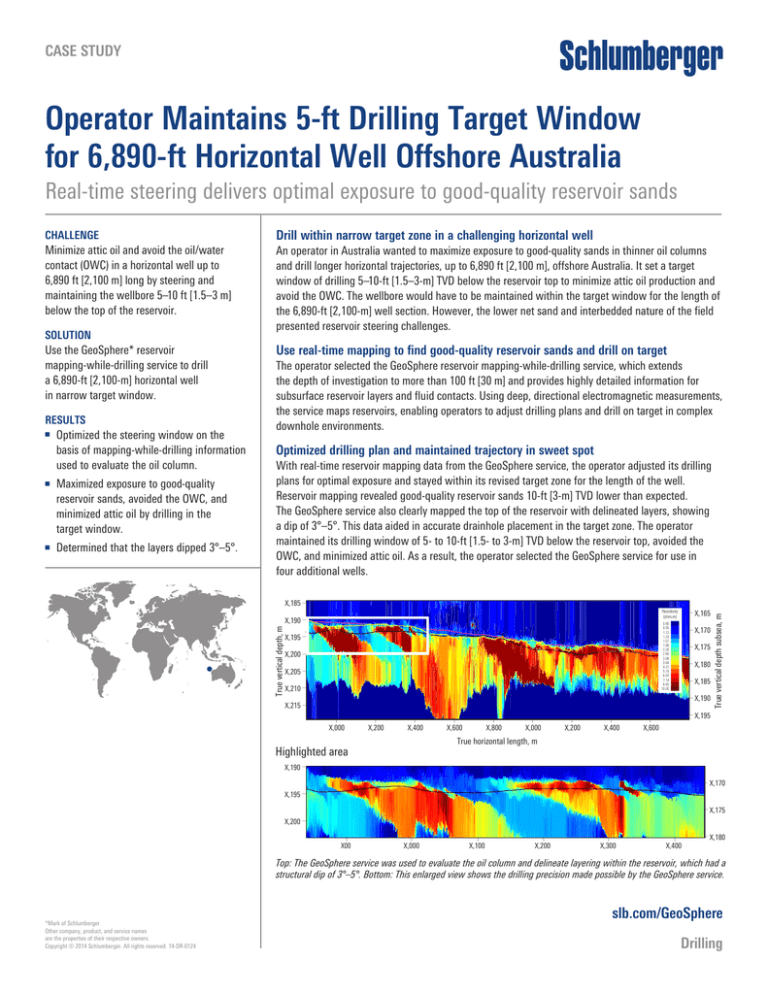

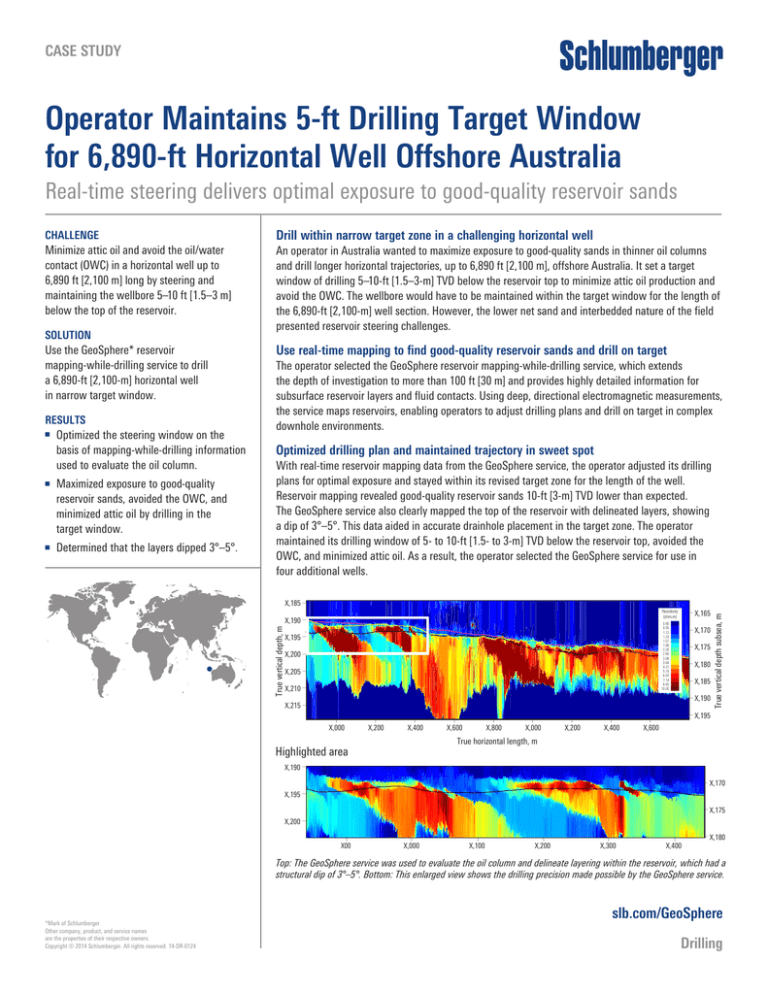

Optimized drilling plan and maintained trajectory in sweet spot

With real-time reservoir mapping data from the GeoSphere service, the operator adjusted its drilling

plans for optimal exposure and stayed within its revised target zone for the length of the well.

Reservoir mapping revealed good-quality reservoir sands 10-ft [3-m] TVD lower than expected.

The GeoSphere service also clearly mapped the top of the reservoir with delineated layers, showing

a dip of 3°–5°. This data aided in accurate drainhole placement in the target zone. The operator

maintained its drilling window of 5- to 10-ft [1.5- to 3-m] TVD below the reservoir top, avoided the

OWC, and minimized attic oil. As a result, the operator selected the GeoSphere service for use in

four additional wells.

True vertical depth, m

– X,165

Resistivity

(ohm.m)

X,190 –

0.80

0.95

1.12

1.33

1.57

1.86

2.20

2.60

3.08

3.64

4.31

5.10

6.03

7.14

8.45

10.00

X,195 –

X,200 –

X,205 –

X,210 –

– X,170

– X,175

– X,180

– X,185

– X,190

X,215 –

True vertical depth subsea, m

X,185 –

– X,195

X,000

X,200

X,400

X,600

X,800

X,000

X,200

X,400

X,600

True horizontal length, m

Highlighted area

X,190 –

– X,170

X,195 –

– X,175

X,200 –

X00

X,000

X,100

X,200

X,300

X,400

– X,180

Top: The GeoSphere service was used to evaluate the oil column and delineate layering within the reservoir, which had a

structural dip of 3°–5°. Bottom: This enlarged view shows the drilling precision made possible by the GeoSphere service.

*­ Mark of Schlumberger

Other company, product, and service names

are the properties of their respective owners.

Copyright © 2014 Schlumberger. All rights reserved. 14-DR-0124

slb.com/GeoSphere

Drilling