How Perform a Compliant Inspection and Update the Site Map

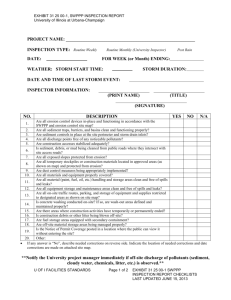

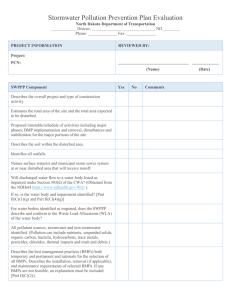

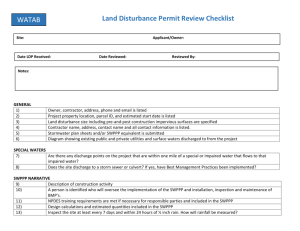

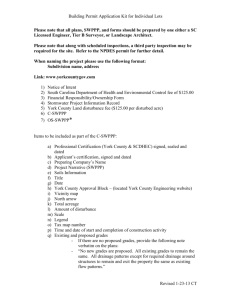

advertisement

How Perform a Compliant Inspection and Update the Site Map 2 of 3 This presentation was produced by the JOHNSON COUNTY STORMWATER MANAGEMENT PROGRAM 1800 W. 56 Highway Olathe, KS 66061 Inspections Inspect the Paperwork Copy of the CGP (construction general permit) Signed NOI (notice of intent) Agency Correspondence Contractor Certifications Site and BMP descriptions Inspection Form Date and time Weather Inspectors name Inspectors qualifications List of BMPs Certification statement Signature block Document Certification Form Spill Form Site Map Limits of Disturbance Discharge points Receiving streams for each discharge point Current locations of all BMPs Site Inspection Public posting Material storage areas Walk the perimeter Stormwater discharge locations This inlet protection device is ineffective. How long has it been since this bmp was inspected and maintained? You should not be able to see light under the fence when properly installed. Trash dumpsters should receive regular maintenance and clean out. Location of dumpster also noted in SWPPP. All construction sites that are pouring concrete must have a designated concrete washout receptacle/area. This site has both trash and track out which must be reported on the inspection. Can you find the problem here? Potential of flooding this intersection. This device is installed and working properly… Problem? The bmp is installed in an active parking. The first silt fence was installed wrong and therefore the stormwater flow went around it. The second silt fence was installed properly but the rock was placed on top of it. Where is the channel protection such as turf reinforcement mat and vegetation? Silt fence is not a good slope break device. This is what happens when the silt fence at the top of the slope is not placed exactly on the contour. It fails after ponding almost two feet of water behind it. A proper rock exit is suppose to shake, bounce and flex the tires to remove the sediment from the trucks before they leave the site. Milled asphalt will not create this effect. This inlet protection needs maintenance. The rock in this channel is too big and therefore provides little or no protection from the stormwater flow. The silt fence is not installed correctly and sediment is going under it The check dams here are not installed properly with the low point in the center, so the water moved around the dam and eroded the slopes of the channel. This is the amount of sediment from erosion of the channel due to an improperly installed bmp. What were they thinking? Is there a detail in the SWPPP for this device? It appears this bmp might have been damaged when the rock was placed. This is why it is a good idea to educate your subcontractors as to the importance of these devices. Make them responsible and liable for damages. When straw is not kept in place with crimping or tackifier, it can float away and clog ditches, waterways or inlets and create flooding. This silt fence cannot hold back erosion from this slope. The slope should have been finished and fine graded when the channel work was being done so both sides could be stabilized at the same time. Mulch has floated and is blocking the channel. This could cause flooding. Where is the erosion control and soil stabilization? The concrete truck driver is not educated about stormwater and doesn’t know where to washout. A little too close for comfort. Remember to place porta-potties, trash dumpsters and storage containers away from inlets and waterways where they could enter a waterbody. Where is our erosion control? Why don’t we have grass growing on the slope? This straw mulch is too deep and might limit vegetation establishment. Can you find five deficiencies with this picture? Remember When Doing an Inspection Inspect every part of compliance Permit paperwork SWPPP Public entry postings Best Management Practices When writing up the inspection – tell the story What needs repaired or replaced When was it repaired or replaced Inspections Keep all the SWPPP materials together in order and readable Make them accessible to contractors and agencies who do inspections Educate your contractors and subcontractors so they understand how important it is to stay in compliance. Source: Jennifer Hildebrandt When you are done with the inspection… update the SWPPP and site maps as necessary The Site Map Dates of BMP Installation and Removal First marks on the site map include: Installation of construction exit/entrance Installation of perimeter control Parking, trailer and lay down areas Maintaining an Updated SWPPP The SWPPP must be amended when the following occur: Changes in design, construction, operation, or maintenance that may effect the discharge of pollutants During any inspections, it is determined the discharges are causing or contributing to water quality exceedances or the SWPPP is ineffective in eliminating or reducing pollutants in the stormwater discharge Changes in the revised SWPPP shall be implemented before the next rain event where practicable. Records of Stabilization Dates when major grading activities occur Dates when construction activities temporarily or permanently cease on any portion of the site Dates when stabilization measures are initiated and complete and any reasons for delays Major Grading Activities Removing topsoil Cut or Fill Stormwater Basin installation Utility installation Storm sewer Sanitary Water Notes on Site Map Notes on Site Map Notes on Site Map Notes on Site Map Forester Media (www.forester.net) Erosion Control Stormwater Grading and Excavating Expedited Settlement Offer The expedited settlement offer is what the EPA uses to assess fines. This is a good checklist to make sure the SWPPP and site are in compliance. The End of “How to Perform Compliant Inspection” Presentation. Continue to “Sediment Control and Pollution Prevention”. Note: review all three presentations before taking the quiz.