LFM Operating Modes

Different Modes. One unified work process.

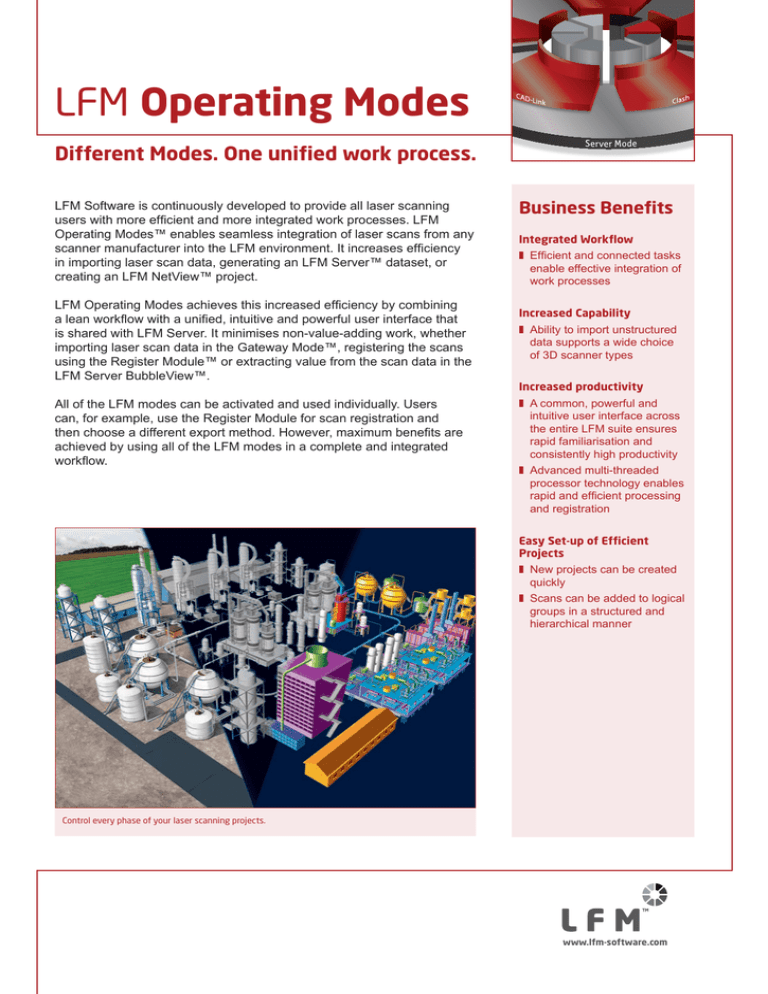

LFM Software is continuously developed to provide all laser scanning

users with more efficient and more integrated work processes. LFM

Operating Modes™ enables seamless integration of laser scans from any

scanner manufacturer into the LFM environment. It increases efficiency

in importing laser scan data, generating an LFM Server™ dataset, or

creating an LFM NetView™ project.

LFM Operating Modes achieves this increased efficiency by combining

a lean workflow with a unified, intuitive and powerful user interface that

is shared with LFM Server. It minimises non-value-adding work, whether

importing laser scan data in the Gateway Mode™, registering the scans

using the Register Module™ or extracting value from the scan data in the

LFM Server BubbleView™.

All of the LFM modes can be activated and used individually. Users

can, for example, use the Register Module for scan registration and

then choose a different export method. However, maximum benefits are

achieved by using all of the LFM modes in a complete and integrated

workflow.

Business Benefits

Integrated Workflow

z Efficient and connected tasks

enable effective integration of

work processes

Increased Capability

z Ability to import unstructured

data supports a wide choice

of 3D scanner types

Increased productivity

z A common, powerful and

intuitive user interface across

the entire LFM suite ensures

rapid familiarisation and

consistently high productivity

z Advanced multi-threaded

processor technology enables

rapid and efficient processing

and registration

Easy Set-up of Efficient

Projects

z New projects can be created

quickly

z Scans can be added to logical

groups in a structured and

hierarchical manner

Control every phase of your laser scanning projects.

www.lfm-software.com

LFM Gateway Mode

LFM Gateway not only provides unparalleled and extensive

connectivity to terrestrial 3D laser scanners; it can also

import other 3D data capture formats, supporting mobile,

hand-held or aerial scanners. Gateway also enables data

export in open, industry-standard formats.

Gateway exploits the latest advances in multi-threaded

and non-blocking computer hardware architecture. Multiple

actions can be performed simultaneously for a more

efficient workflow; for example, registration can start as

soon as scans are imported using the Gateway Mode.

Data from various types of 3D data capture devices can be

imported and consolidated in a single LFM Server dataset.

LFM supports open data exchange standards such as

ASTM E57 to provide users with guaranteed access to their

data, whilst organising data in specific formats for maximum

productivity.

LFM Register

With the same user interface, LFM Register takes raw data

from individual scan positions and rapidly combines them

automatically into a fully coordinated framework. Once

registered, data can be exported for use with downstream

applications from other laser scanning software vendors.

The Target Prediction feature ensures that a user need

only locate one or two targets in the scan data; LFM

automatically locates and fits the remaining ones. This

process is mirrored with respect to the identification/naming

of the targets.

Class leading registration tools and reporting.

Bundle Adjustment considers the location of

a target from every scan position. A mean

value of its 3D location is then calculated

before a scan is re-registered. This process is

continually repeated, increasing accuracy in

scan-to-scan registration.

Inter-cloud registration enables accurate scan

registration without the use of targets. This

is particularly useful for small projects, or

on larger projects where there may be only

one visible target, or even none at all. Intercloud registration progressively refines the

registration between the sets of scan data until

an optimum alignment is achieved.

Take advantage of the latest in computing – perform multiple tasks simultaneously

Register provides detailed registration

quality analysis and reporting. A report can

be downloaded as a project deliverable to

demonstrate that registration accuracy meets

the client’s requirements.

LFM Generator

This single LFM Server-based product enables seamless

creation of LFM NetView™ projects and generation of LFM

Server datasets.

LFM Server Generator™

This creates InfiniteCore™ datasets for use in LFM

Server and AVEVA Everything3D™. It takes registered

scans from any registration application and produces

added-value datasets that are widely used throughout

industry. An intuitive user interface, with enhanced user

assistance, reporting and licensing functions, makes the

process straightforward.

LFM NetView Generator™

Organise and create LFM NetView projects. These can

be online or file based configuration.

LFM Server Mode

LFM Server is the most advanced solution available for

accessing pre-registered laser scan data and working with

it directly in 3D CAD systems. It is simple to use and offers

unrivalled performance and functionality.

There are many different 3D laser scanners and 3D CAD

systems in use today. LFM Server has been developed

to provide users with maximum freedom of choice of both

scanning and design systems. It can read unstructured

data from various scanner types; not only terrestrial laser

scanners but also hand-held, mobile or aerial scanners.

Designed to work with data from even the highestresolution scanner, LFM Server enables users to work with

datasets of unlimited size and exploit photorealistic, 360o

BubbleViews™.

For more information please see the LFM Server product

brochure.

LFM Software Limited, an AVEVA Group company

5 Avocado Court, Commerce Way

Trafford Park, Manchester

M17 1HW, UK

Tel +44 (0) 161 869 0450

Fax +44 (0) 161 869 0451

www.lfm-software.com

LFM Software Limited believes the information in this publication is correct as of its publication date. As part of continued product development, such information is subject

to change without prior notice and is related to the current software release. LFM Software Limited is not responsible for any inadvertent errors. All product names mentioned

are the trademarks of their respective holders.

Copyright © 2013 AVEVA Solutions Limited and its subsidiaries. All rights reserved. LFM/DS/OM/13