Hydraulic Rock Storage A new concept for storing

advertisement

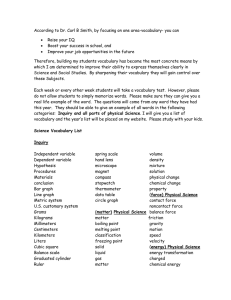

Hydraulic Rock Storage A new concept for storing electricity 2 3 The solution for storing large amounts of electricity from renewable energy sources — Renewable energy from wind and solar sources is now making a rapidly increasing contribution to global power supplies. Solar energy in particular is always available in many regions of the world and this can be converted relatively cheaply into electricity. In order to ensure a con­ tinuous supply of electrical power it is necessary to have a highly efficient system capable of storing the day‘s electrical output for a period of several hours. The Hydraulic Rock Storage (HRS) can do this. 4 The Hydraulic Rock Storage Using proven technology for smart storage solutions 5 Method of operation — The HRS consists of a large piston of rock that has been detached from the surrounding strata using validated and proven mining techniques. The rock piston and its surrounding cylinder are sealed by means of a synthetic film liner. This method is already used by the international tunnel construction industry. The sealing ring itself is composed of a rolling bellow sealing, which works effectively in high stress situations (see page 9). A pump driven by surplus electricity forces water beneath the rock piston, causing it to lift. When electri­city is required the pressu­rised water is directed through a turbine to generate alternating-current electricity that can then be fed directly into the supply grid. This process has an efficiency rating of over 80%. r Basic principle — The HRS operates on the principle of converting electrical into potential energy by lifting of a large mass of rock. Here the amount of energy that can be stored is pro­ portional to the rock mass and the height by which it can be raised. In the case of the HRS this results in the remarkable characteristic that a piston whose diameter and height are both doubled exhibits a sixteen-fold energy storage capability. As the cost of the operation to detach a rock piston of twice the reference size is only four times the reference amount, the storage capacity of the system becomes significantly more cost-effective. This particular physical law favours the construction of large HRS units. Economic systems would have a minimum diameter of some 150 metres, which results in a storage capa­ city of one gigawatt-hour. When used in combination with photovoltaics the HRS can guarantee stable production costs for many years on end. 2r r Storage Capacity Mass ~ r 3 Height ~ r Capacity ~ r4 Construction cost: b ~ r 2 — Cost per kWh ~ 1/r 2 capacity [GWh] 0.20 1.0 2.1 3.2 8.0 124 radius, height [m] 50 75 90 100 125 250 diameter [m] 100 150 180 200 252 500 volume of water [1000 m3 ] 392 1325 2290 3141 6284 49087 21 31 37 41 52 103 pressure [bar] 6 Constructing the HRS — Recognised mining techniques are employed for the construction of the HRS. A supply tunnel is driven down to the bottom level of the planned cylinder. The floor of the cylinder is then detached using mechanised drill and blast technology and the area is sealed. Conventional drilling and blasting is also used to excavate down through the sidewalls of the piston from ground level. All the exposed surfaces are sealed with geomembrane or metal to protect against environmental effects and water ingress. The required infrastructure is also put in place at the same time, primarily the access tunnel and generator chamber. The construction work is expected to last 3 to 4 years from the construction start date. spiral tunnel working level connecting tunnel working level base sole connecting tunnel 150 meter The construction of the piston is very similar to projects in the coal mining industry and tunnel construction. 7 A possible application of mining process 4m Mining process application in Kiruna, Sweden (View on illustration: unrolled cylinder wall). — The mining engineering procedures required for the project are well tested and can be executed by a number of mining contractor companies. Various rock bolting techniques can be employed, according to the type of rock strata encountered, so as to ensure that the piston and cylinder remain stable in the long term. This provides for an operating life of some 100 years, which is comparable with that of today‘s road tunnels. rock strata shotcrete watertight sheeting concrete slab with mounting high-grade strata 8 9 The Sealing The rolling membrane is hidden in the slit between piston and cylinder. The width of the slit is about 20 centimeter. Piston Detail Features — The rolling membrane seal is the preferred tech­­ no­logy to seal the system. With the rolling membrane the appearance of the cylinder in the countryside can also be varied according to taste. This means, for example, that lightcoloured concrete can be used instead of a metallic surface. – – – – – ypical pressure at sealing: 40 Bar T Forces are absorbed by steel cables Flexible towards fluctuating position of cylinder Self-centering Production similar to steel belted tires 10 The Storage in Operation An example of HRS of one gigawatt-hour in real scale. Combining a large PV power plant and a Hydraulic Rock Storage System results in a reliable power supply. — After the HRS has been completed the pumping operation can commence for the first piston lift. This would normally take place during daylight hours when the sun is shining or when there is wind blowing. The piston would then be lowered during the evening or night-time hours, or when the wind is light, so that electricity can be generated from the stored energy. This process would be repeated on a daily basis, thereby provi­ding a consistent supply of electri­city. The opera­ ting life of the system is therefore practically unlimited, since the storage facility, i.e. the rock mass, essentially does not wear out. The operating equipment, and especially the pumps, turbines and generator, will be designed for a service life of 60 years or more. If necessary, these units can be replaced at the end of their operating life. 11 — The daily cycle of elec­tricity demand depends on local lifestyle. In most countries the sun is already settled when a lot of energy is needed. Therefore, it is useful, to collect and store the solar energy during the daytime and provide the useful electric power at the evening and during night time. This time shift needs efficient and very reliable storage systems. The Hydraulic Rock Storage does not wear out, even if it is used for the daily cycle. Power [MW] 200 PV Electricity for Storage 180 160 140 Direct Used PV Electricity 120 100 80 Usage of Stored Electricity 60 40 20 0 0 1 2 3 4 5 6 7 8 9 10 11 12 Example of the energy supply, that is possible with a 200 MW peak power PV system and a one gigawatt hour Hydraulic Rock Storage (150 meter diameter). 13 14 15 16 17 18 19 20 21 22 23 Time [h] 12 Location Factors — The HRS is best built at locations with a solid bedrock. The most favourable sites comprise stable, non-faulted rock such as granite or compact layers of another solid rock material. The initial situation first has to be assessed in detail by a team of geologists. In addition, and depending on the size of the storage facility, two million cubic metres of water have to be provided only once and held ready for transfer in a reservoir. The HRS is best suited to regions where – t here is a high solar radiation level and/or a large wind yield – power supply security is indispensable –conventional pumped storage systems cannot be built due to inadequate elevation. The necessary water for the hydraulic piston is stored in a reservoir. No continuous water supply is necessary. 13 Advantages of the Hydraulic Rock Storage System –Cost effectiveness: scaling of costs with increasing radius, costs fall at 1/r² – E fficiency: about 80% (comparable with pumped storage) –Project can be constructed using proven and validated technologies – Relatively low space requirement – Long operating life of several decades –Lower water consumption than pumped storage systems (about 1/4) –Black start capability and high flexibility in various operating modes 14 — The concept of the Hydraulic Rock Storage system was invented by Professor Heindl and is developed by Stuttgart-based Heindl Energy GmbH. A team of specialists in geology, geophysics, mining and civil engineering provide advice and assistance during the development process. The company is majority-owned by Professor Eduard Heindl and is financed by Swiss-based HTG Ventures AG. Contact Heindl Energy GmbH Wankelstrasse 14 70563 Stuttgart / Germany Phone +49 711 46926713 www.heindl-energy.com info@heindl-energy.com Picture Credits ©fotolia.com/trekandphoto; ©iStock.com/andreiorlov, InnaFelker, pavel_klimenko, SoleilC, vallefrias; Heindl Energy GmbH Computer Generated Imagery: designconcepts GmbH Professor Dr. Eduard Heindl, inventor of the Hydraulic Rock Storage System. 15 www.designconcepts.de Contact Phone +49 711 46926713 www.heindl-energy.com info@heindl-energy.com 1/2015 Heindl Energy GmbH Wankelstrasse 14 70563 Stuttgart / Germany