Ancient Iron and Bronze Pieces from La Tejada: Characterization

advertisement

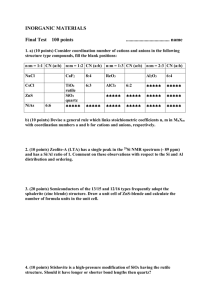

Feature Archaeotechnology Ancient Iron and Bronze Pieces from La Tejada: Characterization Studies J.M. Gómez de Salazar, M.I. Barrena, and A. Soria This article describes the microstructural characterization of ancient iron and bronze found in the archaeological site of La Tejada (Palencia, Spain). This work offers insight into the manufacturing and technological knowledge of Roman society, which would be of interest for several branches of science including metallurgy, archaeology, and chemistry. INTRODUCTION The abundance of raw materials present in the Iberian Peninsula enabled civilizations throughout the region to flourish.1 One example is Palencia, a province in the northwest of Spain where numerous villages2 and archaeological sites from different eras were discovered.3 Some of these sites were Figure 1. A map of La Tejada. villages and others were thermal baths. La Tejada, situated on the bank of the Cueza River and dated in the second century A.D, is an example of a thermal bath (Figure 1).4 The thermal bath consisted of three buildings made of recycled construction materials. The pillars that supported the floor (Figure 2) allowed the circulation of hot air from a furnace to the different buildings.4 The mosaics (Figure 3) show the archaeological and artistic richness of the Roman society. The studies of artifacts found in La Tejada, an iron nail and some bronze rods, in particular (Figure 4), focused on their microstructural and mechanical characterization. The metallographic characterization was performed using optical microscopy, scanning-electron microscopy (SEM), x-ray diffraction (XRD), and hardness testing. This characterization required consolidation (by immersing the pieces in methacrylate solution) to prevent the losses of oxides and patinas. Moreover, an etching reactive was used to reveal the microstructure: Nital (a solution of HNO 3 in ethanol) for the iron microstructure and an acid solution of FeCl3 in ethanol for the bronze microstructure.5 Oxides and slags were not electric conductors, so SEM required a previous sputtering process. RESULTS AND DISCUSSION XRD Analysis Figure 2. A floor supported by pillars. Figure 3. Mosaics with geometrical forms. An XRD analysis was carried out on the surface of the iron nail and Over the last 40 years, there has been a discernible increase in the number of scholars who have focused their research on early industrial organizations, a field of study that has come to be known as Archaeotechnology. Archaeologists have conducted fieldwork geared to the study of ancient technologies in a cultural context and have drawn on the laboratory analyses developed by materials scientists as one portion of their interpretive program. Papers for this department are solicited and/or reviewed by Michael Notis, a professor and director of the Archaeometallurgy Laboratory (www.Lehigh.edu/~inarcmet) at Lehigh University. 14 JOM • June 2004 the bronze rods. The analysis of the lands that easily fell apart from the nail showed the presence of quartz (SiO2), calcite (CaCO3), and akageneite (FeOOH) compounds (Table I). The XRD analysis of the lands that fell apart from the bronze rods showed the presence of quartz (SiO2) and cuprite (Cu2O) compounds (Table II). Powder diffraction lines identification show that all these pieces were buried in a quartzite soil. Cuprite and akagenite compounds were corrosion products of these samples. Optical Microscopy Optical microscopy images of the nail show a hypoeutectoid steel in the external head zone, with a microstructure consisting of ferrite matrix with pearlite precipitated in the grain boundary (Figure 5). In internal zones, the micrographs show a microstructure with ferrite and pearlite phases. This zone presents less pearlite content due to the decrease of carbon percent (Figure 6). The optical microscopy shows an α-bronze microstructure in the rods (Figure 7). This microstructure presents grains with different sizes. The size of the grain decreases near the external zone because of the deformation effect (cold deformation). Scanning Electron Microscopy The SEM study found that the iron consisted of pearlite and ferrite, where the ferrite phase presents an acicular morphology (Widmanstätten) (Figure 8). The rods were manufactured with 7 wt.% tin (Table III), leading to an α-bronze microstructure that has some twins (Figure 9). An interesting fact was observed in the internal zones, where two different types of slags were found (Figure 10). The difference between the slags was their chemical composition (Table IV)—dark slag (Figure 11) contained more copper than bright slag, which had more tin (Figure 12). a 2 cm Figure 4. The La Tejada artifacts: (a) a bronze rod and (b) an iron nail. b 1 cm Table I. Powder Diffraction File Identification (Surface of the Nail) No. 2θ d (Å) Rel. I (%) Mineral ASTM No. h k l 1 2 3 4 5 6 7 8 9 10 11 12 13 20.98 26.82 29.54 35.06 36.74 39.66 40.50 42.62 50.30 55.06 60.10 67.94 68.34 4.234 3.324 3.024 2.559 2.446 2.273 2.227 2.121 1.814 1.668 1.540 1.380 1.373 19.6 100 15.8 7.2 12.4 10.7 21.9 7.9 15.8 9.9 13.4 7.9 10.6 SiO2 FeOOH CaCO3 FeOOH SiO2 CaCO3 SiO2 SiO2 SiO2 SiO2 SiO2 SiO2 SiO2 33-1161 34-1266 72-1650 34-1266 33-1161 72-1650 33-1161 33-1161 33-1161 33-1161 33-1161 33-1161 33-1161 1 3 1 2 1 1 0 2 1 2 2 2 2 0 1 0 1 1 1 1 0 1 0 1 1 0 0 0 4 1 0 3 2 0 2 2 1 2 3 Table II. Powder Diffraction File Identification (Surface of the Rod) No. 1 2 3 4 5 6 7 8 9 2θ d (Å) Rel. I (%) Mineral ASTM No. h k l 20.86 26.62 29.54 36.42 39.82 42.34 42.78 49.78 61.38 4.258 3.349 3.024 2.467 2.264 2.135 2.114 1.832 1.510 18.82 25 23.3 100 26.1 41.8 47.2 27.2 42.9 SiO2 SiO2 Cu2O Cu2O SiO2 Cu2O SiO2 SiO2 Cu2O 33-1161 33-1161 78-2076 78-2076 33-1161 78-2076 33-1161 33-1161 78-2076 1 1 1 1 1 2 2 1 2 0 0 1 1 0 0 0 1 2 0 1 0 1 2 0 1 2 0 50 µm 50 µm Figure 5. An optical micrograph of external head zones of the nail. Figure 6. An optical micrograph of internal zones of the nail. Hardness Test The rods were tested using Vickers hardness. The Vickers hardness is homogeneous along all pieces with values in an interval of 115 ± 10 HV. A hardness test was carried out on the nail’s head zone and on a longitudinal section. In the head zone, the hardness 2004 June • JOM Table III. Chemical Piece Composition Element Table IV. Slags Chemical Composition Wt.% Element Si Fe Cu Sn 0.72 0.20 92.04 7.05 O Si Cu Sn Dark Slag (wt.%) Bright Slag (wt.%) 11.64 2.25 82.09 4.03 15.41 0.84 69.51 14.24 15 increases from the external zones (100 HV) to the central zones (220 HV) due to deformation hardening and the subsequent decrease in carbon content on this forging. In the longitudinal section, the medium hardness value was 190 ± 30 HV, though the hardness values decrease near the tip zone. CONCLUSIONS 100 µm 60 µm Figure 7. An optical micrograph of αbronze. Figure 8. A scanning electron microscopy image of the nail. Ferrite presents an acicular morphology. Based on characterization results, one can conclude that Roman society in Palencia knew how to forge iron and bronze, and understood the hardness processes that took place during cold work. References 100 µm 100 µm Figure 9. A scanning electron microscopy image of α-bronze (7% Sn). Figure 10. Elongated slags in the bronze matrix. 1. R. Martín Valls, Historia de Palencia I. Edades Antigua y Media (Palencia, Spain: Excma. Diputación Provincial Palencia, 1984), pp. 15–53. 2. J.M. Gómez de Salazar and A. Soria, “Characterizing Ancient Iron Pieces from La Olmeda,” JOM, 52 (12) (2000), pp. 15–17. 3. Montenegro Duque, Historia de Palencia I. Edades Antigua y Media (Palencia, Spain: Excma. Diputación Provincial Palencia, 1984), pp. 54–62. 4. M.A. García Guinea, Guía de la villa romana de Quintanilla de la Cueza (Palencia) (Palencia, Spain: Diputación de Palencia, 1990). 5. F.A. Calvo, Metalografía práctica (Madrid, Spain: Alhambra, 1971). José María Gómez de Salazar is a professor, Maria Isabel Barrena is a teacher, and Alicia Soria is a recent Ph.D. graduate with the Materials Science and Metallurgical Engineering Department at the Complutense University of Madrid, Spain. 40 µm 30 µm Figure 11. Detail of a dark slag presented in Figure 10. Figure 12. Detail of bright slag presented in Figure 10. For more information, contact J.M. Gómez de Salazar, Universidad Complutense de Madrid, Facultad de Ciencias Químicas, Department de Ciencia de los Materiales e Ingenieria Metalúrgica, Avda. Complutense S/N, Ciudad Universitaria, 28040 Madrid, Spain; +34-91-394-4351; fax +34-91394-4357; e-mail gsalazar@quim.ucm.es. The inaugural edition of TMS Letters is available on-line. The first issue focuses on the topic of dislocations and contains ten technical updates from papers presented at the 2004 TMS Annual Meeting. Future issues will focus on such topics as: • Polydomain Structures • Thermodynamics of Alloys • Computational Thermodynamics and Phase Transformations • Educational Issues in Transport Phenomena in Materials Processing • Processing Microstructure and Properties of Powder-Based Materials • Microstructural Stability • The Role of Grain Boundaries in Materials Design • General Abstracts TMS members can access their free subscriptions through the TMS Document Center at doc.tms.org. 16 JOM • June 2004