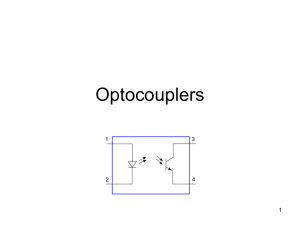

Optocoupler

advertisement