Composites Science and Technology 59 (1999) 2015±2024

Determination of elastic constants of glass/epoxy unidirectional

laminates by the vibration testing of plates

A.K. Bledzki a, A. Kessler a, R. Rikards b,*, A. Chate b

a

Institut fuÈr Werkstotechnik, UniversitaÈt-GH-Kassel, MuÈnchebergstr. 3, Kassel D-34125, Germany

Institute of Computer Analysis of Structures, Riga Technical University, Kalku iela 1, LV-1658 Riga, Latvia

b

Received 9 November 1998; received in revised form 2 March 1999; accepted 9 April 1999

Abstract

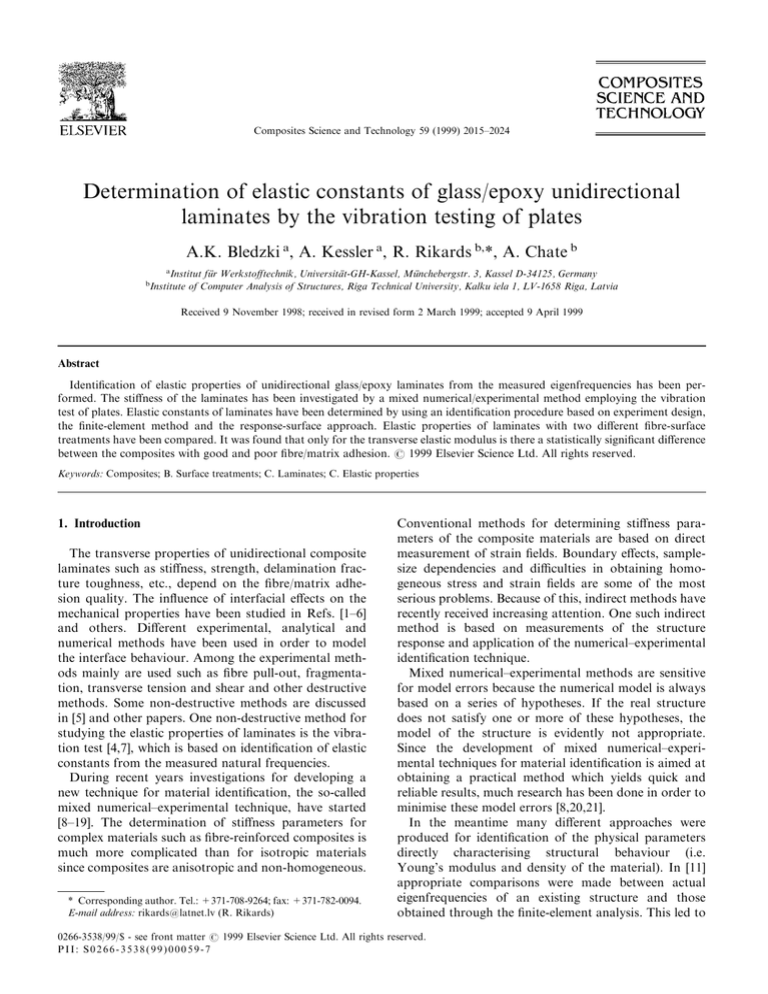

Identi®cation of elastic properties of unidirectional glass/epoxy laminates from the measured eigenfrequencies has been performed. The stiness of the laminates has been investigated by a mixed numerical/experimental method employing the vibration

test of plates. Elastic constants of laminates have been determined by using an identi®cation procedure based on experiment design,

the ®nite-element method and the response-surface approach. Elastic properties of laminates with two dierent ®bre-surface

treatments have been compared. It was found that only for the transverse elastic modulus is there a statistically signi®cant dierence

between the composites with good and poor ®bre/matrix adhesion. # 1999 Elsevier Science Ltd. All rights reserved.

Keywords: Composites; B. Surface treatments; C. Laminates; C. Elastic properties

1. Introduction

The transverse properties of unidirectional composite

laminates such as stiness, strength, delamination fracture toughness, etc., depend on the ®bre/matrix adhesion quality. The in¯uence of interfacial eects on the

mechanical properties have been studied in Refs. [1±6]

and others. Dierent experimental, analytical and

numerical methods have been used in order to model

the interface behaviour. Among the experimental methods mainly are used such as ®bre pull-out, fragmentation, transverse tension and shear and other destructive

methods. Some non-destructive methods are discussed

in [5] and other papers. One non-destructive method for

studying the elastic properties of laminates is the vibration test [4,7], which is based on identi®cation of elastic

constants from the measured natural frequencies.

During recent years investigations for developing a

new technique for material identi®cation, the so-called

mixed numerical±experimental technique, have started

[8±19]. The determination of stiness parameters for

complex materials such as ®bre-reinforced composites is

much more complicated than for isotropic materials

since composites are anisotropic and non-homogeneous.

* Corresponding author. Tel.: +371-708-9264; fax: +371-782-0094.

E-mail address: rikards@latnet.lv (R. Rikards)

Conventional methods for determining stiness parameters of the composite materials are based on direct

measurement of strain ®elds. Boundary eects, samplesize dependencies and diculties in obtaining homogeneous stress and strain ®elds are some of the most

serious problems. Because of this, indirect methods have

recently received increasing attention. One such indirect

method is based on measurements of the structure

response and application of the numerical±experimental

identi®cation technique.

Mixed numerical±experimental methods are sensitive

for model errors because the numerical model is always

based on a series of hypotheses. If the real structure

does not satisfy one or more of these hypotheses, the

model of the structure is evidently not appropriate.

Since the development of mixed numerical±experimental techniques for material identi®cation is aimed at

obtaining a practical method which yields quick and

reliable results, much research has been done in order to

minimise these model errors [8,20,21].

In the meantime many dierent approaches were

produced for identi®cation of the physical parameters

directly characterising structural behaviour (i.e.

Young's modulus and density of the material). In [11]

appropriate comparisons were made between actual

eigenfrequencies of an existing structure and those

obtained through the ®nite-element analysis. This led to

0266-3538/99/$ - see front matter # 1999 Elsevier Science Ltd. All rights reserved.

PII: S0266-3538(99)00059-7

2016

A.K. Bledzki et al. / Composites Science and Technology 59 (1999) 2015±2024

the identi®cation of parameters which can be used for

the model calibration as well as for the detection of

damaged zones in the structure.

Numerical±experimental identi®cation methods are

mainly used in structural applications [8±19]. For

example, in [8] elastic properties of laminated composites have been identi®ed by using experimental eigenfrequencies. The stiness parameters were identi®ed

from the measured natural frequencies of the laminated

composite plate by direct minimisation of the identi®cation functional. A similar approach to identifying the

stiness properties of the laminated composites was

used in [18,19,22]. In [20] an improved plate model was

used for identi®cation of elastic constants of the laminate. In [23] it was shown that the mixed numerical±

experimental method can also be used for identi®cation

of damping properties of polymeric composites.

In the present study the numerical±experimental

method for identi®cation of mechanical properties of

laminated polymeric composites from the experimental

results of the structure response has been further developed. The dierence between the conventional [8,20]

and the present approach is that, instead of direct

minimisation of the identi®cation function, experimental

design is used, by which response surfaces of the function to be minimised are obtained. The response surface

approximations are obtained by using information on

the behaviour of a structure in the reference points of

the experiment design. Note that ®nite-element modelling of the structure is performed only in the reference

points. The function to be minimised describes the

dierence between the measured and numerically calculated parameters of the response of structure. By minimising the function the identi®cation parameters were

obtained. The method was employed to identify the

elastic properties of the laminates from the measured

eigenfrequencies of the plates. The main advantage of the

present method is a signi®cant reduction of the computational eort. Previously this method was used for the

solution of the optimum design problems [24±27].

In the present study the numerical±experimental

method has been applied for identi®cation of elastic

properties of glass/epoxy laminates with two dierent

®bre-surface treatments. Experiments were performed

on laminated plates and about 16 natural frequencies

were measured. Elastic properties obtained from vibration tests have been compared with those from the

transverse tensile test.

types of surface treatments. The ®rst type was treated by

epoxy dispersion with aminosilane to promote good

®bre/matrix adhesion. More details about this ®bre

treatment can be found in [28,29]. For this composite

the notation EP is used. The second type was sized with

polyethylene to prevent ®bre/matrix adhesion. For this

composite the notation PE is used. A Ciba Geigy Ltd.

Araldite epoxy system (LY556/917/DY070) with an

ultimate tensile strain of 3.3% was used as the matrix

material.

Unidirectionally reinforced test samples were produced on a winding machine. The content of micropores

was below 0.75% by volume. The glass ®bre-reinforced

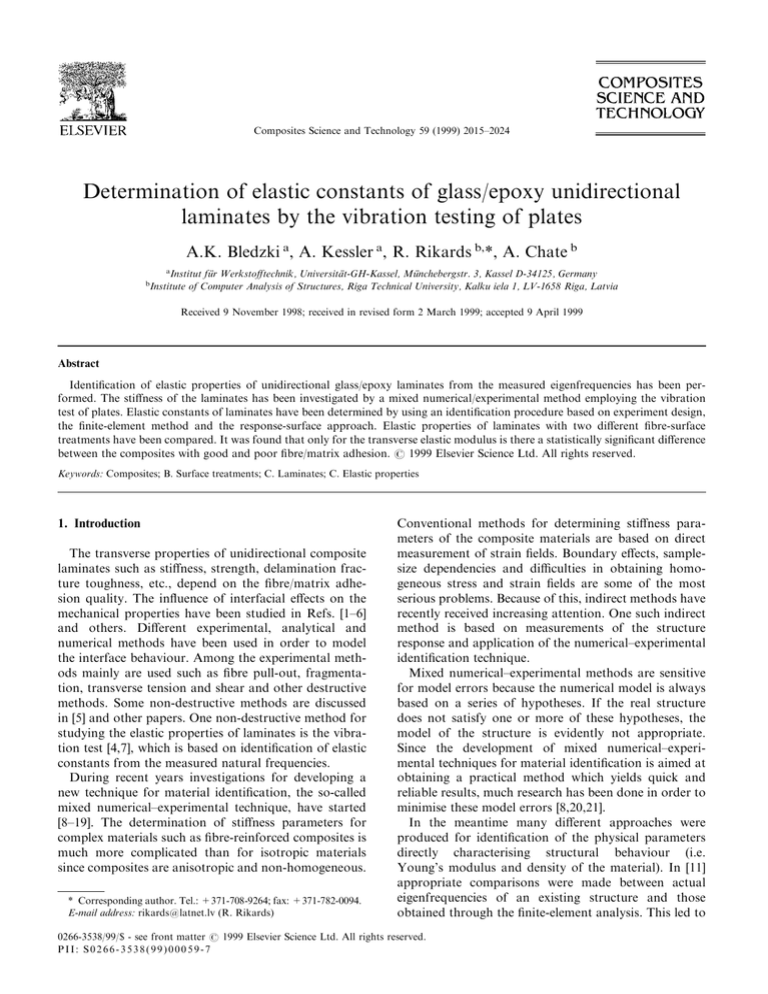

plates (see Fig. 1) were prepared with given geometric

parameters. The total number of plies was eight in order

to get a plate thickness of approximately 2 mm. The EP

and PE laminates were produced by following the standard cure cycle recommended by Ciba Geigy Ltd. To

improve the quality of the plates and to reduce the void

content, the plates were placed in a vacuum before curing. Specimens were cut out with a diamond wheel and

kept under standard conditions (23 C and 50% of relative humidity) until testing. All tests were performed in

the same conditions. The ®bre content of the specimens

was about 501.5 vol%. The density was measured for

each specimen. The specimen geometric parameters and

density for the unidirectionally (UD) reinforced PE

composite plates are presented in Table 1. Similar data

for the EP composite plates were given in [7].

2.2. Vibration tests

The eigenfrequencies of the test plates were measured

by a real-time television (TV) holography. The samples

having mean dimensions of 140 mm140 mm2 mm

were hung upon two threads in order to simulate free±

free boundary conditions. The sample was located in

front of the holographic testing device. A piezoelectric

resonator (sensor) was glued on one corner to excite the

sample plate at increasing frequencies. The sensor is of

2. Experimental

2.1. Material

Unidirectionally reinforced laminates were produced

from E-glass ®bres (12 mm, 63 tex) with two dierent

Fig. 1. Geometry of the unidirectionally reinforced plate.

A.K. Bledzki et al. / Composites Science and Technology 59 (1999) 2015±2024

circular shape with a diameter 25 mm located at the

coordinates x a ÿ 12:5 mm and y b ÿ 12:5 mm (see

Fig. 1). The mass of the sensor is ms 3:5 g.

The plate is illuminated by laser light and imaged by

CCD (charged couple device) array, resulting in a

speckled image on the PC monitor. When the plate is

deformed (excited), this interference pattern is slightly

modi®ed. Digital substraction of two consecutive interference patterns yields a fringe pattern depicting the

surface displacements of the plate. The nodal lines of

the vibration modes can be easily identi®ed on the

monitor in the form of white lines on the speckled

image. The digital substraction of two consecutive pictures helps to minimise noises, such as rigid body

motion of the hung plate. This measurement technique

was described in more detail in [4,30].

Experiments were performed for all plates considered

(see Table 1) and about 16 ¯exural eigenfrequencies

were measured. In Table 2 the most frequently found

experimental plate ¯exural frequencies for the PE composite are presented. The mode shapes were also recognized in the experiment. Experimentally measured

frequencies for the EP composite were presented in [7].

Table 1

Geometric parameters and density of the PE composite plates

3

3

Sample

a (m)

b (m)

h 10 (m)

(kg/m )

PE01

PE02

PE03

PE04

PE05

PE06

Mean

0.1399

0.1401

0.1400

0.1400

0.1400

0.1401

0.1400

0.1401

0.1401

0.1399

0.1401

0.1404

0.1403

0.1401

2.095

2.072

2.060

2.070

2.010

2.060

2.061

1884

1889

1890

1900

1890

1900

1892

2017

3. Parameters of identi®cation and criterion

The numerical±experimental method proposed for the

identi®cation of the elastic constants from the vibration

tests consists of the following stages. In the ®rst stage

the physical experiments are performed. Also the parameters to be identi®ed, the domain of search and criterion containing experimental data are selected. In the

second stage the ®nite-element method is used in order

to model the response of the structure and calculations

are performed in reference points of the variables to be

identi®ed. The reference points are determined by using

a method of experiment design. In the third stage the

numerical data obtained by the ®nite-element solution

in the reference points are used in order to determine

simple functions (response surfaces) for a calculation of

the structure response. In the fourth stage, on the basis

of the simple models and experimentally measured

values of the structure response, the identi®cation of the

elastic properties is performed. For this a corresponding

functional is minimised by using the method of nonlinear programming.

3.1. Parameters of identi®cation

Identi®cation of parameters is performed from the

experimentally measured eigenfrequencies. It is assumed

that the plate dimensions (see Fig. 1), plate mass and the

layer stacking sequence are known. The parameters to

be identi®ed are ®ve elastic constants of a transversely

isotropic plate [8]:

. two Young's moduli, E1 , E2 E3

. shear moduli, G12 G13

Table 2

Experimental plate ¯exural frequencies fi (Hz) for the PE composite

Mode

Mode shape

Specimens

Mean

i

m, n

PE01

PE02

PE03

PE04

PE05

PE06

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1.1

2.0

2.1

0.2

1.2

3.0

2.2

3.1

3.2

0.3

4.0

4.1

2.3

4.2

3.3

5.0

164

270

415

493

587

742

891

±

±

±

1470

1600

1750

2050

2240

2400

162

266

413

487

584

725

886

±

±

±

1470

1600

1735

2036

±

2395

167

270

420

485

590

740

920

±

1340

±

1470

1570

±

2040

2200

2320

170

270

430

480

590

750

915

±

±

1340

1480

1610

1760

2100

±

2440

173

276

419

491

587

747

910

±

±

1320

1480

1630

1760

±

±

2450

170

270

410

470

570

720

910

±

±

1290

1440

1560

±

±

±

2310

168

270

418

484

585

737

905

±

1340

1317

1468

1595

1751

2057

2220

2386

2018

A.K. Bledzki et al. / Composites Science and Technology 59 (1999) 2015±2024

where !~ 1 is the ®rst numerical eigenfrequency calculated

with the prior selected value of a longitudinal Young's

modulus E01 (initial guess value) of the layer [8].

. Poisson's ratio, 12 13

. shear modulus, G23

E2

2

1 23

The plate is composed of unidirectionally reinforced

layers with material axis 1±2±3, where 1 is the ®bre

direction and 2, 3 are directions transverse to the ®bres.

The unidirectional layer is assumed as homogeneous

and transversely isotropic with respect to the ®bre

direction. The parameters to be identi®ed can be

expressed in terms of dimensionless constants [8]

E2

;

2 4 ÿ 4

E1

E2

G12

0 ;

3 1

1 ÿ 212 ÿ 4

E1

E1

E2

G12

4 1

1 612 ÿ 4

0 ;

E1

E1

5 4

G23 G12

0

E1

1

E2

E1

2

The inverse relations of Eqs. (1) are as follows

4 ÿ 3 G23 25 ÿ 0:5

8 ÿ 2 ÿ 33 ÿ 4

;

8 ÿ 22 E1

80

3

Now the vector of parameters x to be identi®ed is

de®ned through dimensionless quantities i

x x1 ; x2 ; x3 ; x4 2 ; 3 ; 4 ; 5

4

These parameters can be evaluated through the

identi®cation procedure using the experimental eigenfrequencies of the laminated composite rectangular

plate of constant thickness h, length a and width b (see

Fig. 1).

Let the experimental angular eigenfrequencies be

I is the

designated by !1 ; !2 ; :::; !I , where

ÿ

number of

measured eigenfrequencies fi i !~ i 2fi . The corresponding numerical eigenfrequencies fi

!~ i 2fi for

the set of material parameters i are represented by

!~ 1 ; !~ 2 ; :::; !~ I . Let us consider the scaling parameter C

which is chosen according to the relation [8]

C

!21

ÿ !~ 21 E01

x

h

i2

I

!2i ÿ C!~ i

x2

X

!4i

i2

5

6

It is seen that criterion (6) is a nonlinear function of

the identi®cation parameters x. The identi®cation of the

elastic constants x is performed on the basis of information obtained from the measurements of the I lowest

frequencies. The identi®cation problem is formulated as

follows

min

x

7

Subject to constraints

g 1

x 4 ÿ 2 > 0

g 2

x

E2 4 ÿ 2 G12 8 ÿ 2 ÿ 33 ÿ 4

;

;

E1

4

E1

160

12

The functional to be minimised describes deviation

between the measured !i and numerically calculated

!~ i

x frequencies [8]

x

where

0 1 ÿ 212

3.2. Identi®cation functional and minimization problem

or

E2

>0

E1

8 ÿ 2 ÿ 33 ÿ 4

# > 0 or

4 ÿ 3 2 4 ÿ 2

16 1 ÿ

8 ÿ 22

4

8

"

9

G12

>0

E1

25 ÿ 0:5

8 ÿ 2 ÿ 33 ÿ 4

g 3

x "

# > 0 or

4 ÿ 3 2 4 ÿ 2

8 1ÿ

8 ÿ 22

4

10

G23

>0

E1

r

4 ÿ 3 4

> 0 or

g4

x ÿ

4 ÿ 2

8 ÿ 22 r

E1

ÿ j12 j > 0

E2

11

max

;

min

i 4i 4i

12

i 2; 3; 4; 5

and the lower min

limits of the idenThe upper max

i

i

ti®cation parameters will be chosen dierent for each

numerical example of identi®cation (see below). These

values determine the so called domain of interest

(domain of search). Constraints (8)±(11) denote conditions of a positive de®nite elasticity matrix.

A.K. Bledzki et al. / Composites Science and Technology 59 (1999) 2015±2024

The optimum values for the dimensionless material

parameters i (i 2; 3; 4; 5) that satisfy Eq. (7) and

constraints (8)±(12) were obtained by using a random

search method [24]. The value of Young's modulus of

the layer in the ®bre direction E1 can be easily evaluated, since C and 0 are known. The steps of this evaluation are shown below.

4. Finite-element solution

The eigenvalue problem for harmonic vibrations of

the plate can be represented by

Ku !2 Mu

13

Here K is the stiness matrix of the plate, M is the

mass matrix and u is the displacement vector. The

eigenvalue relation (13) for the mode u1 which corresponds to the ®rst experimental eigenfrequency !1 can

be written in an equivalent form placing E1 in evidence:

E1 K u1 !21 Mu1

14

Here E1 K K is the stiness matrix. Taking into

account relation (5) this equation can be written as

CE01 K u1 C!~ 21 Mu1

15

hence

E1 CE01

16

where E01 is the initial guess value given to the Young's

modulus in the ®bre direction of the layer and E1 is the

corresponding identi®ed mechanical property. After

evaluation of the optimum value of x the remaining

mechanical properties are calculated by inverse relations

(3).

The eigenvalue problem (13) was solved by the subspace iteration method [31] and using a triangular ®nite

element of laminated thick plate with a shear correction

[32]. In order to avoid `shear locking' a selective integration technique was applied. A 2222 regular mesh

(968 ®nite elements) was considered in order to achieve

the necessary accuracy for at least 16 ®rst eigenvalues of

the laminated plate with FFFF (all edges free) boundary conditions.

5. Method of experiment design for identi®cation

problems

For direct identi®cation of the elastic properties of a

material it is necessary to perform a multiple iterated

®nite element procedure. Such a direct procedure was

2019

used by Mota Soares et al. [8] and also in [19]. On each

iterative stage the eigenvalue problem for the linear

system was solved by the ®nite element method or by

the Ritz method and the nonlinear programming algorithm applied in order to minimise directly the identi®cation functional (6). Such a procedure requires very

large computational eorts.

Instead of direct minimisation of the criterion (6), a

method based on experiment design can be used. The

selection of points in the domain of interest where the

response must be evaluated is commonly called design

of experiments. The choice of experiment design can

have a large in¯uence on the accuracy of the approximation and the cost of constructing the response surface [33]. A commonly used experiment design is the Doptimality criterion [34]. Other experiment design

methods require an a priori knowledge of the functional

form of the response. This knowledge might not be

available. The method of experiment design in which

the a priori knowledge of the functional form of the

response is not necessary was proposed in [24]. This

method previously was used in the solution of optimisation problems for sandwich and laminated composite

structures [25±27]. The identi®cation and optimum

design problems are very similar. In both cases the

solution can be obtained by minimisation of the function

considered. The method of experiment design for the

solution of the identi®cation problems was outlined in [7].

Further, as an example the method is shown for

identi®cation of elastic constants for PE composite by

the use of the mean values of plate ¯exural frequencies

(see last column in Table 2). The mean values of the

geometric parameters and density of the plates are taken

from Table 1.

Firstly the experiment design with four variables

(n=4) and 35 reference points is selected. The second

step is selection of the domain of interest. The upper

and lower limits of the identi®cation parameters are

taken as follows

5 GPa4E2 440 GPa;

5 GPa4G23 430 GPa;

5 GPa4G12 430 GPa;

0:2412 40:4

17

The initial guess value of Young's modulus is taken

E01 =40 GPa, which is related to E1 by expression (16).

After selection of the domain of interest the experiment

design is employed. The matrix ij of the experiment

design for n 4 and k 35 is used and the parameters

of identi®cation in the reference points of the domain of

interest (17) are calculated by the expression

x

j i xmin

j

ÿ

1 max

xj ÿ xmin

Bij ÿ 1

j

kÿ1

Here i 1; 2; :::; k and j 1; 2; :::; n.

18

2020

A.K. Bledzki et al. / Composites Science and Technology 59 (1999) 2015±2024

Further, in these reference points (18) the ®nite-element solution of the eigenvalue problem (13) is performed and at least 16 ®rst numerical frequencies of the

PE composite are obtained for each reference point. A

similar procedure was repeated also for the other plates

(PE01±PE06).

6. Approximation of the response surface

Techniques from experiment design and responsesurface methodology [35] are used to build the approximate models from the data in the reference points.

Information on the behaviour of an object can be

obtained from the computer solution in the reference

points of the experiment design. The information can be

represented as a data table, where the response function

y

x of the object is to be in relationship with the variables

x. In our case there are four identi®cation variables

representing the elastic constants of the material. The goal

is, by using the data only in the reference points [in our

case these data are obtained by the ®nite-element solution of the eigenvalue problem (13) in the reference

points], to obtain the relation y

x in the mathematical

form or the so-called response surface. Here such

mathematical models (response surfaces) have been

obtained for the ®rst 16 eigenfrequencies of the laminated plate.

The existing methods of regression analysis are based

on the principle that the equation form is known a

priori, and the problem is to ®nd coecients of the

equation. However, in most cases the form of the equation must also be determined. Such a method was proposed earlier [24±27] to obtain a simple mathematical

model for the structural optimisation problems. This

method was brie¯y outlined and applied to the identi®cation problems in [7].

Further, the procedure to get the approximation y

x

for the ®rst natural frequency f1 of the PE composite

plate is shown. In order to obtain the equation of

regression, the resint program [24] was employed. In

this program the perspective functions are selected by

using the least-squares estimation. Then a step-by-step

reduction procedure of the number of terms in the

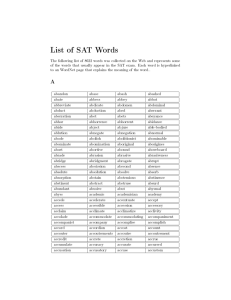

model is applied. The diagram of reduction of terms in

the model for the ®rst frequency is shown in Fig. 2. It is

seen that the ®rst break in the diagram corresponds to

the regression equation with eight terms. The second

break corresponds to the expression with four terms.

This means that the model with eight terms should be

chosen. On eliminating the eighth term, the correlation

with the data of numerical experiment decreases more in

comparison with the previous step of reduction. In the

expression with four terms, only three parameters of

identi®cation are presented. Thus, the simple model

(response surface) for the ®rst frequency of the PE

Fig. 2. Diagram of the term reduction for the function f1 (x).

composite plate (mean values of geometric parameters

and experimentally measured frequencies) is given by

expression with eight terms:

f1

x 158:5 ÿ 4:3z1 ÿ 15:44z2 ÿ 8:14z3

0:234z4 ÿ 0:567z22 ÿ 1:43z2 z3

ÿ 0:454z1 z2

19

where the normalised variables zi are introduced:

z1 ÿ28:5 10x1 ;

z3 ÿ6:07 4:43x3 ;

z2 ÿ5:84 8:67x2 ;

z4 ÿ3:39 3:83x4

20

Here the identi®cation parameters x are related to the

elastic constants of the layer by Eqs. (1)±(3). Similar

models (response surface) to expression (19) were also

obtained for the other frequencies and for other plate

specimens (PE01±PE06).

Note that there are no general rules for the procedure

of reduction of terms in the model (response-surface

function) and it is necessary to acquire some experience

to obtain appropriate function. Another possibility for

building a model is using engineering knowledge of the

true functional form of the response [36].

7. Results of identi®cation for the PE composite

Identi®cation of the elastic constants of the PE composite from the measured eigenfrequencies was performed in two dierent ways. In the ®rst approach the

identi®cation was carried out for each sample (PE01±

PE06). In the second approach the mean values of

the measured frequencies (see Table 2) were taken for the

identi®cation. Such a method can be realised since the

A.K. Bledzki et al. / Composites Science and Technology 59 (1999) 2015±2024

geometric parameters and density of the samples (see

Table 1) are almost the same for all specimens and the

scatter of the measured frequencies is rather small (see

Table 2). However, since frequencies are very sensitive

to thickness h and density of the plate, in the case of

larger scatter of the measurements the ®rst approach

must be used, i.e. the identi®cation of the elastic constants should be performed for each specimen.

For the plate specimen with a sensor there are some

dierences in calculation of the mass matrix M in Eq.

(13) in comparison with the plate without sensor. In

order to represent more accurately the inertia forces of

the plate, the mass of sensor ms should be taken into

account. In the ®nite-element modelling it is assumed

that the ®nite elements where the sensor is located have

the same thickness h as the plate, but for these ®nite

elements an equivalent density eqv is calculated:

eqv

2021

points and the function (response surface) obtained by

the approximation have been selected. Such selection is

necessary in order to minimise the approximation

errors. The vibration modes selected for identi®cation

are given in Table 4. In the last row (Mean) the vibration modes selected for identi®cation from the mean

values (the second approach) are presented.

Veri®cation of the results was performed by the ®niteelement method (FEM) and through the independent

experiments. For the ®nite-element analysis the elastic

constants obtained by the identi®cation procedure were

used [see Table 3, the mean values

2 ]. Results are

shown in Table 5. Residuals were calculated by the

expression

i

f FEM

x ÿ f exp

i

i

100

f exp

i

21

ms

Fs h

Here Fs is the area of the sensor.

Results of identi®cation are presented in Table 3.

Utilising the ®rst way the elastic constants were identi®ed for each specimen using the data from Tables 1 and

2, and then the mean values

1 and standard deviations s

1 were calculated. In the second approach at the

beginning the mean values of frequencies (see Table 2)

and geometric parameters (see Table 1) were calculated.

These mean values were used as input data and then the

identi®cation procedure was applied. The results

obtained by identi®cation utilising the second way are

also given in Table 3 and denoted by

2 .

In Table 3 it is seen that results for the in-plane elastic

constants E1 ; E2 ; G12 and 12 obtained by both approaches are in good agreement. The transverse shear modulus G23 can not be reliable determined from the

measured frequencies since the plates were too thin

(h=a=1/70) for identi®cation of this property. In this

case thick plates should be used.

It should be noted that the number of frequencies

which were selected for the identi®cation was dierent

for dierent specimens. For the identi®cation only the

modes with a high values of the coecient of correlation

(correlation higher than 98%) between the data

obtained by the ®nite-element solution in the reference

7.1. Comparison with independent tests

It is of interest to compare the elastic constants

obtained from the vibration test through the identi®cation (see Table 3) with the values obtained by the independent tension test. The same PE composite was tested

in static tension transverse to the ®bres [4]. The composite also was tested in the ®bre direction.

Results obtained by independent tests are compared

in Table 6. For the tension test in the ®bre direction,

six specimens were tested. In the tension test transverse

to the ®bre direction, eight specimens were tested. The

data reduction was performed according to DIN 53457

and DIN 29971, i.e. the modulus E1 was calculated as a

slope between the points for the strain level 0.05 and

0.25%, and the modulus E2 was calculated as a slope

between the points for the stress at 10 and at 50% of the

maximum stress [4]. The sample mean and standard

deviations are presented.

In order to evaluate the dierences between the values

obtained by independent tests the methods of statistics

should be applied. The t-test [38] for comparing mean

values of two normal distributions (variances being

equal) was employed. Assuming the two mean values of

the test groups 1 (vibration test) and 2 (tension test)

Table 3

Elastic constants of the PE composite obtained by identi®cation

Property

PE01

PE02

PE03

PE04

PE05

PE06

1 s

1

2

E1 (GPa)

E2 (GPa)

G12 (GPa)

G23 (GPa)

12

38.69

11.80

4.65

4.90

0.263

40.12

11.80

4.67

7.19

0.213

39.80

12.16

5.01

1.31

0.137

38.75

12.30

5.19

2.78

0.315

39.57

12.67

5.73

7.71

0.358

36.16

11.99

5.26

±

0.246

38.841.44

12.120.33

5.090.41

4.782.76

0.2550.077

39.15

12.16

5.11

2.06

0.269

2022

A.K. Bledzki et al. / Composites Science and Technology 59 (1999) 2015±2024

Table 4

Vibration modes used for identi®cation

Plate

PE01

PE02

PE03

PE04

PE05

PE06

Mean

Mode i

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

+

+

+

+

+

+

+

+

+

+

+

ÿ

+

+

+

+

+

+

+

ÿ

+

ÿ

ÿ

ÿ

ÿ

+

+

+

+

+

+

+

+

+

+

+

+

+

+

ÿ

+

+

+

+

ÿ

ÿ

ÿ

ÿ

+

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

+

+

+

+

+

+

+

+

+

ÿ

+

+

ÿ

+

+

+

+

+

ÿ

ÿ

+

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

+

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

Table 5

Flexural frequencies fi (Hz) (i 1; 2; :::; 16) and residuals i for PE

composite

Mode i

FEM

Exp.

i (%)

Used in identi®cation

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

168

270.5

418

477

585

737

905

±

1340

1317

1468

1595

1751

2057

2220

2386

167.9

266.4

430.7

484.5

588.3

740.7

887.6

919.6

1382

1320

1449

1588

1737

2073

2232

2337

0.06

1.37

3.04

0.10

0.56

0.50

1.31

±

3.13

0.23

1.29

0.44

0.80

0.78

0.54

2.06

+

+

+

+

+

+

+

ÿ

ÿ

ÿ

ÿ

+

+

+

+

ÿ

Table 6

Elastic constants for Pe composite obtained by independent tests

Property

Tension test [4]

Vibration test

E1 (GPa)

E2 (GPa)

39.501.18

8.471.76

38.841.44

12.120.33

are equal, then the sample means x1 and x2 will not

dier signi®cantly at some con®dence level if

j x2 ÿ x 1 j

s

2

n1 ÿ 1s1

n2 ÿ 1s22 1

1

n1 n2 ÿ 2

n1 n2

< t=2; n1 n2 ÿ 2

22

Here, s1 , s2 are the standard deviations and n1 , n2 are

the number of samples in the specimen groups 1 and 2,

respectively. On the right hand side of Eq. (22)

t=2; n1 n2 ÿ 2 is the Student's coecient for the signi®cance

level on n1 n2 ÿ 2 degrees of freedom. These values

can be obtained from the t-tables [38].

Using the t-test for comparing the vibration test

results for E1 (group 1, number of samples n1 6) and

the tension test results (group 2, number of samples

n2 6) the expression on the left hand side of Eq. (22) is

0:868 < t0:025;10 2:228. For calculations the 95% con®dence level was assumed, i.e. signi®cance level

0:05. Therefore, the results of t-test shows that for

E1 there is no statistically signi®cant dierence between

the values obtained by the tension and vibration tests

(the t-test passes).

Utilising the t-test for comparing the vibration test

results for E2 (group 1, number of samples n1 6) and

the tension test results (group 2, number of samples

n2 8) according Eq. (22) the t-test fails, i.e. the

expression on the left hand side of Eq. (22) is

11:62 > t0:025;12 2:179. So, the t-test shows that there

is a statistically signi®cant dierence between the values

obtained by the transverse tension and vibration test

(the t-test fails). For the transverse modulus E2 the

values obtained in the vibration test are higher. The

reason is that in the vibration test a dynamic (storage)

modulus is measured. Since the epoxy matrix is a viscoelastic material the storage modulus could be higher

than the static one. The in¯uence of the viscoelastic

behaviour is more signi®cant in the direction transverse

to the ®bres. Since the glass ®bres can be assumed as

an elastic material the in¯uence of the viscoelastic

behaviour of the matrix in the ®bre direction is smaller.

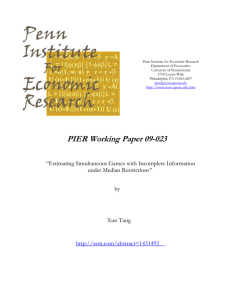

Other reason of dierences is that in the static tensile

test after few loading steps due to poor ®bre/matrix

adhesion a break in the stress/strain curve can be

observed (see Fig. 3). For this test the modulus E2 was

calculated as a slope between the points for the stress at

10 and at 50% of the maximum stress. Due to the nonlinearity in the stress/strain diagram the value of E2

calculated in such a way is rather a secant modulus than

modulus of elasticity. For the material in which ®bre/

matrix debonding occurs in the ®rst few steps of loading

it is dicult to measure the transverse modulus of

elasticity in the static test. On the other hand for the

A.K. Bledzki et al. / Composites Science and Technology 59 (1999) 2015±2024

2023

Table 7

Comparison of dierent properties

Fig. 3. Typical stress/strain diagram in transverse tension for PE

composite.

Property

Test

EP composite

PE composite

t-test (22)

E1 (GPa)

E1 (GPa)

E2 (GPa)

E2 (GPa)

G12 (GPa)

Vibration

Tension [4]

Vibration

Tension [4]

Vibration

39.031.14

38.451.62

12.690.20

10.350.69

5.330.23

38.841.44

39.501.18

12.120.33

8.471.76

5.090.41

Pass

Pass

Fail

Fail

Pass

compared (see Table 7). For the all elastic constants

statistics are available and according to Eq. (22) the ttest has been performed. Results of the t-test are presented in the last column. Comparing the composites

PE and EP it can be concluded that for both the vibration and the tension test there is no statistically signi®cant dierence between the values E1 (the t-test

passes). The same can be concluded for the inplane

shear modulus G12 . At the same time for the stiness

property transverse to the ®bre direction E2 for both the

vibration and the transverse tension test there is a statistically signi®cant dierence between the composites

PE and EP (the t-test fails). The transverse stiness for the

PE composite with poor ®bre/matrix adhesion is lower.

9. Conclusions

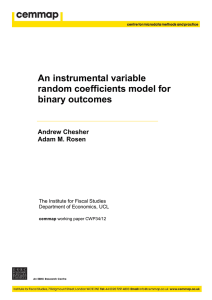

Fig. 4. Typical stress/strain diagram in transverse tension for EP

composite.

material with good ®bre/matrix adhesion (EP composite) the stress/strain curve is nearly linear till ultimate

stress (see Fig. 4) and the value of E2 can be measured

in the static test [4]. For the EP composite the E2 modulus obtained in the vibration test [7] is also about 20%

higher than modulus obtained in the static tensile test.

This could be due to the in¯uence of viscoelasticity in

the dynamic test.

8. Comparison of elastic properties for PE and EP

composites

In order to compare the laminates with good ®bre/

matrix adhesion (EP composite) and poor ®bre/matrix

adhesion (PE composite), dierent material properties

can be used. For example, in [4] the transverse strength

and in [37] the interlaminar fracture toughness properties

have been compared for the same composites considered here. In the present paper elastic properties are

The main advantage of the present identi®cation

method is signi®cant reduction (about 50±100 times) of

the computational eorts in calculating the numerical

frequencies, which participate in the functional to be

minimised. Another advantage of the identi®cation

method used is that all elastic constants are determined

only from one vibration test by using a plate sample.

Thus, the material is not destroyed by cutting samples

in order to determine dierent elastic constants. Comparing elastic properties for the composites with good

(EP composite) and poor (PE composite) ®bre/matrix

adhesion it was shown that the transverse stiness for

the PE composite is lower. The t-test shows that there is

a statistically signi®cant dierence for E2 values

obtained in the vibration and the static tension test.

Acknowledgements

The investigations concerning the development of the

identi®cation method for elastic properties of laminated

composites were sponsored through Grant 96.0504. The

authors are pleased to acknowledge the ®nancial support by the Latvian Council of Science. Thanks are also

due to German Federal Ministry of Science and Technology (Grant WTZ LET010.97) and Latvian Ministry

of Education and Science (Grant 6292/98) for their

generous support of this paper.

2024

A.K. Bledzki et al. / Composites Science and Technology 59 (1999) 2015±2024

References

[1] Mahiou H, BeÂakou A. Modelling of interfacial eects on the

mechanical properties of ®bre-reinforced composites. Composites

Part A 1998;29A:1035±48.

[2] Steen M, ValleÂs JL. Interfacial bond conditions and stress distribution in a two-dimensionally reinforced brittle-matrix composite. Composites Science and Technology 1998;58:313±30.

[3] Wacker G, Bledzki AK, Chate A. Eect of interphase on the

transverse Young's modulus of glass/epoxy composites. Composites Part A 1998;29A:619±26.

[4] Kessler A, Bledzki, AK. Does the interface control the transverse

modulus of GFRP? Composite Interfaces, in press.

[5] Mai K, MaÈder E, MhuÈle M. Interphase characterization in composites with new non-destructive methods. Composites Part A

1998;29A:1111±9.

[6] Keusch S, Queck H, Gliesche K. In¯uence of glass ®bre/epoxy

resin interface on static mechanical properties of unidirectional

composites and on fatigue performance of cross ply composites.

Composites Part A 1998;29A:701±5.

[7] Rikards R, Chate A, Steinchen W, Kessler A, Bledzki AK.

Method for identi®cation of elastic properties of laminates based

on experiment design. Composites Part B 1999;30B:279±89.

[8] Mota Soares CM, Moreira de Freitas M, ArauÂjo AL. Identi®cation of material properties of composite plate specimens. Composite Structures 1993;25:277±85.

[9] Sol H, De Visscher J, De Wilde WP. Identi®cation of the viscoelastic material properties of orthotropic plates using a mixed

numerical/experimental technique. In: Brebbia CA, Carlomagno

GM, editors. Computational methods and experimental measurements VI, vol. 2: stress analysis. London/New York: Elsevier

Applied Science, 1993. p. 131±42.

[10] Sol H. Identi®cation of anisotropic plate rigidities using free

vibration data. PhD thesis, Free University of Brussels, 1986.

[11] Bolognini L, Riccio F, Bettianli F. A modal technique for the

identi®cation of stiness and mass parameters in large structures.

In: Brebbia CA, Carlomagno GM, editors. Computational methods and experimental measurements VI, vol. 2: stress analysis.

London/New York: Elsevier Applied Science, 1993. p. 337±52.

[12] Frederiksen PS. Identi®cation of temperature dependence for

orthotropic material moduli. Mechanics of Materials 1992;13:79±90.

[13] De Wilde WP. Identi®cation of the rigidities of composite systems by mixed numerical/experimental methods. In: Vautrin A,

Sol H, editors. Numerical identi®cation of composites. London/

New York: Elsevier Applied Science, 1991. p. 1±15.

[14] Grediac M, Vautrin A. Mechanical characterization of anisotropic plates: experiments and results. Eur J Mech A/Solids

1993;12(6):819±38.

[15] Link M, Zou Zh. A two steps procedure to identify physical parameters of composite material structures using vibration test data.

In: Proc. Int. Conf. on Vibration Engineering, ICVE 94, Beijing.

Beijing: International Academic Publishers, 1994. p. 217±24.

[16] Moussu F, Nivoit M. Determination of elastic constants of

orthotropic plates by a modal analysis method of superposition. J

Sound and Vibrations 1993;165(1):149±63.

[17] Pedersen P. Optimization method applied to identi®cation of

material parameters. In: Eschenauer HA, Thierauf G, editors.

Discretization methods and structural optimizationÐprocedures

and applications. Berlin: Springer Verlag, 1989. p. 277±83.

[18] Frederiksen PS. Identi®cation of material parameters in anisotropic platesÐa combined numerical±experimental method. PhD

thesis, Department of Solid Mechanics, The Technical University

of Denmark, 1992.

[19] Frederiksen PS. Experimental procedure and results for the

identi®cation of elastic constants of thick orthotropic plates. J

Compos Mater 1997;31(4):360±82.

[20] Frederiksen PS. Application of an improved model for the identi®cation of material parameters. Mech Compos Mater and

Struct 1997;4:297±316.

[21] Frederiksen PS. Numerical studies for the identi®cation of elastic

constants of thick orthotropic laminates. Eur J Mech A/Solids

1997;16:117±40.

[22] ArauÂjo AL. MeÂtodo numeÂrico/experimental para carazterizacËaÄo

mecaÏnica de materiais compoÂsitos. MSc. thesis, Technical University of Lisabon, Mech. Eng. Dept., IST, 1995 (in Portuguese).

[23] De Visscher J, Sol H, De Wilde WP, Vantomme J. Identi®cation

of damping properties of orthotropic composite materials using a

mixed numerical experimental method. Appl Compos Mater

1997;4(1):3±33.

[24] Rikards R. Elaboration of optimal design models for objects

from data of experiments. In: Pedersen P, editor. Optimal design

with advanced materials. Proceedings of the IUTAM Symposium, Lyngby, Denmark, 18±20 August, 1992. Amsterdam: Elsevier Science Publishers, 1992. p. 148±62.

[25] Rikards R, Chate A, BaÂcklund J. Optimal design of sandwich

plates based on planning of experiments. In: Olho N, Rozvany

GI, editors. Proc. 1st World Congress of Structural and Multidisciplinary Optimization, 28 May±2 June 1995, Goslar, Germany. Pergamon, 1995. p. 569±74.

[26] Rikards R, Chate A. Optimal design of sandwich and laminated

composite plates based on planning of experiments. Structural

Optimization 1995;10(1):46±53.

[27] Rikards R. Minimum weight design of sandwich and laminated

composite structures. Mech Compos Mater 1995;31(1):51±64.

[28] Wacker G. Experimentell gestuÈtzte Identi®kation ausgewaÈahlter

Eigenschaften glasfaserverstaÈrkter Epoxidharze unter BeruÈucksichtigung der Grenzschicht. PhD Dissertation, University

of Kassel, Kassel, Germany, 1996 (in German).

[29] Bledzki AK, Lieser J, Wacker G, Frenzel H. Characterization of

the surfaces of treated glass ®bres with dierent methods of

investigation. Composite Interfaces 1997;5(1):41±53.

[30] Yang LX, Steinchen W, Schut M, Kupfer G. Precision measurement and nondestructive testing by means of digital phase shifting speckle pattern shearing interferometry. Measurement

1995;16:149±60.

[31] Bathe K-J. Finite element procedures in engineering analysis.

Englewood Clis (NJ): Prentice Hall, 1982.

[32] Rikards R, Chate A, Korjakin A. Damping analysis of laminated

composite plates by ®nite element method. Engineering Computations 1995;12:61±74.

[33] Roux WJ, Stander N, Haftka RT. Response surface approximations for structural optimization. Int J Numer Meth Engng

1998;42:517±34.

[34] Van Campen DH, Nagtegaal R, Schoofs AJG. Approximation

methods in structural optimization using experimental designs for

multiple responses. In: Eschenauer H, Koski J, Osyczka A, editors.

Multicriteria design optimization. Berlin: Springer, 1990. p. 205±28.

[35] Box GEP, Draper NR. Empirical model-building and response

surfaces. New York: Wiley, 1987.

[36] Vanderplaats GN. Numerical optimization techniques for engineering design with applications. New York: McGraw Hill, 1984.

[37] Rikards R, Korjakin A, Buchholz F-G, Wang H, Bledzki AK,

Wacker G. Interlaminar fracture toughness of GFRP in¯uenced

by ®bre surface treatment. J Compos Mater 1998;32(17):1528±59.

[38] Lederman W, editor. Handbook of applicable mathematics,

vol. 6. statistics. Part A. New York: Wiley, 1984.