Comparison of UV vs. Sodium Hypochlorite for Wastewater

advertisement

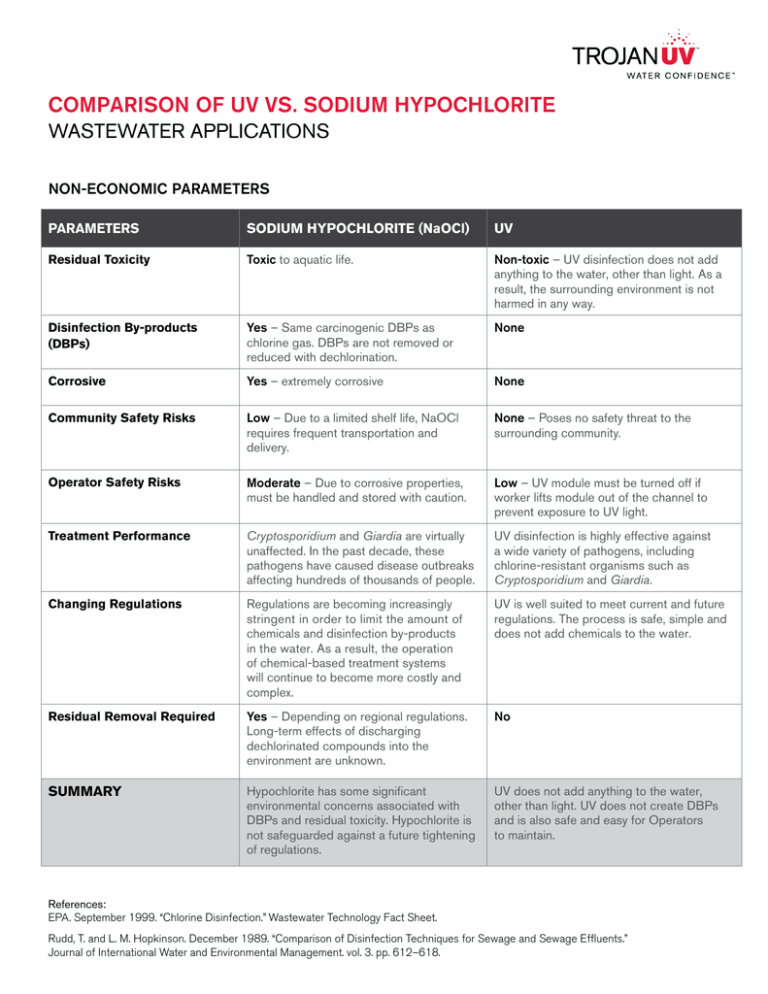

Comparison of UV vs. Sodium Hypochlorite Wastewater Applications Non-Economic Parameters Parameters Sodium Hypochlorite (NaOCl) UV Residual Toxicity Toxic to aquatic life. Non-toxic – UV disinfection does not add anything to the water, other than light. As a result, the surrounding environment is not harmed in any way. Disinfection By-products (DBPs) Yes – Same carcinogenic DBPs as chlorine gas. DBPs are not removed or reduced with dechlorination. None Corrosive Yes – extremely corrosive None Community Safety Risks Low – Due to a limited shelf life, NaOCl requires frequent transportation and delivery. None – Poses no safety threat to the surrounding community. Operator Safety Risks Moderate – Due to corrosive properties, must be handled and stored with caution. Low – UV module must be turned off if worker lifts module out of the channel to prevent exposure to UV light. Treatment Performance Cryptosporidium and Giardia are virtually unaffected. In the past decade, these pathogens have caused disease outbreaks affecting hundreds of thousands of people. UV disinfection is highly effective against a wide variety of pathogens, including chlorine-resistant organisms such as Cryptosporidium and Giardia. Changing Regulations Regulations are becoming increasingly stringent in order to limit the amount of chemicals and disinfection by-products in the water. As a result, the operation of chemical-based treatment systems will continue to become more costly and complex. UV is well suited to meet current and future regulations. The process is safe, simple and does not add chemicals to the water. Residual Removal Required Yes – Depending on regional regulations. Long-term effects of discharging dechlorinated compounds into the environment are unknown. No SUMMARY Hypochlorite has some significant environmental concerns associated with DBPs and residual toxicity. Hypochlorite is not safeguarded against a future tightening of regulations. UV does not add anything to the water, other than light. UV does not create DBPs and is also safe and easy for Operators to maintain. References: EPA. September 1999. “Chlorine Disinfection.” Wastewater Technology Fact Sheet. Rudd, T. and L. M. Hopkinson. December 1989. “Comparison of Disinfection Techniques for Sewage and Sewage Effluents.” Journal of International Water and Environmental Management. vol. 3. pp. 612–618. Comparison of UV vs. Sodium Hypochlorite Wastewater Applications Cost Analysis WWTP with Existing Hypochlorite Disinfection ITEM SODIUM HYPOCHLORITE & DECHLORINATION ULTRAVIOLET Capital Costs $0 $234,000 Annual Costs $70,000 $14,163 ITEM Annual O&M Costs SODIUM HYPOCHLORITE $802,900 ULTRAVIOLET $162,900 Net Present Value $802,900 $396,400 Capital on Costs Return Investment (Yrs) $0 Annual Costs $70,000 Present Value of & DECHLORINATION 4.9 Design Flow: 10 MGD Average Flow: 2.9 MGD Service Life: 20 years Internal Rate of Return: 6.0% Design Criteria: 65% UVT with 25% over design for State Redundancy Requirement $234,000 $14,163 Present Value of Value Cost Comparison Table 1: Present Annual O&M Costs $802,900 $162,900 Converting to UV will save the WWTP more than $55,000 in annual O&M costs. ($0.09 ITEM/Kw was used for power costs) SODIUM HYPOCHLORITE ULTRAVIOLET Net Present Value $802,900 & DECHLORINATION Return on Investment (Yrs) 4.9 Capitalwith CostsExisting Hypochlorite $0 WWTP Disinfection Annual Costs $396,400 $571,000 $133,267 $43,000 ITEM Annual O&M Costs SODIUM HYPOCHLORITE $1,528,900 ULTRAVIOLET $493,200 Net Present Value $1,528,900 $1,064,200 Capital on Costs Return Investment (Yrs) $0 Annual Costs $133,267 $43,000 Present Value of Annual O&M Costs $1,528,900 $493,200 Net Present Value $1,528,900 $1,064,200 Present Value of Return on Investment (Yrs) & DECHLORINATION 8.2 $571,000 8.2 Table 2: Present Value Cost Comparison Converting to UV will save the WWTP more than $90,000 in annual O&M costs. ($0.09 /Kw was used for power costs) Design Flow: 35 MGD Average Flow: 10 MGD Service Life: 20 years Internal Rate of Return: 6.0% Design Criteria: 65% UVT with 25% over design for State Redundancy Requirement