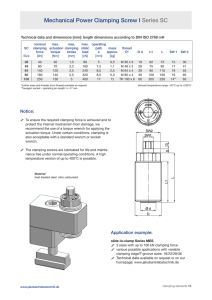

standard clamping elements

advertisement