Static Var Compensators: not just for reactive po

advertisement

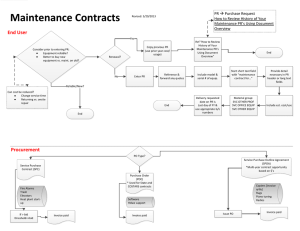

Main feature chapter IiI Making energy available to all, today and tomorrow Static VAr Compensators: not just for Alstom Grid has recently delivered an SVC that is operated mainly in power oscillation damping control mode. When system transfer conditions allow, the SVC may also be used as a reactive power reserve. 38 Alstom Grid///Spring-Summer 2011 The VAr in Static VAr Compensators (SVC) stands for Volt-Ampere reactive (VAr) and is the unit used to measure reactive power in an AC power system. Typically the SVC is used as a voltage or a reactive power controller at the point of common coupling. Power damping control methods are often provided too, but they are usually operated in parallel with voltage or reactive power control, and only part of the reactive capacity of the SVC is allocated for damping controls. The Kangasala SVC (KA SVC) built by Alstom Grid in Finland for the Scandinavian network The Kangasala SVC installation. RTDS testing of control system. ments were specified.” These included at least 98 percent annual availability for forced outages and at most three forced outages per year. Meeting availability targets reactive power is unusual, as Power Systems Engineer Pauli Halonen explains. “The customer, Fingrid Oyj, needed its main control mode to be power oscillation damping (POD) control. However, the SVC also has the traditional voltage control and reactive power control modes that can be activated as a backup source for reactive power or to support the system voltage. Since the KA SVC is applied to enhance operational reliability, and in future may be applied to relieve limitations in transfer capacity during network congestions, high availability and reliability require- To achieve the availability requirement, the KA SVC was equipped with duplicated and fully redundant control, protection and DC auxiliary power systems. Separate cooling systems were implemented for each Thyristor Controlled Reactor (TCR) and Thyristor Switched Capacitor (TSC) branch. The design allows KA SVC to be operated with any combination of SVC components as long as the fifth harmonic filter bank remains in service. The structure of the 20 kV bus and the placement of the components on the 20 kV yard allows maintenance and repairs to be carried out on the components on one side of the building while the other components are still in operation. The redundancy controller monitors the integrity of both control systems and decides which control system is active. The POD control mode is specified to damp the inter-area power oscillations in the frequency range of 0.2 Hz to 0.6 Hz. It consists of six first-order, fully adjustable transfer functions whose output is dead-band filtered. The output of the dead-band function is multiplied by output gain and converted to the SVC reactive power output request value. The whole POD control branch is therefore a sixth-order transfer function. “The purpose is to provide a fully adjustable POD control base to satisfy present and future user demands,” says Halonen. “The POD control parameters are specified by the customer; they can also be changed later on by the user.” Parameters can be changed through the remote or local control of the SVC. The SVC has shown that it increases the operational safety margin. Successful testing The SVC controls were extensively tested during the commissioning. In addition to typical step response, control mode transition and reactor switching tests, the response of power oscillation control was tested by modulating the input of the POD controller using a numerical signal generator implemented as part of the SVC controls. The results were compared to results achieved from PSCAD transient simulation software showing a high correlation between results, even though the network model used in PSCAD was a simplified version. Alstom Grid///Spring-Summer 2011 39 Main feature chapter IiI Making energy available to all, today and tomorrow M o r e The effect of the SVC on the system oscillation damping was lastly tested by carrying out the same change in system transfer conditions with different SVC control modes. The change in transfer conditions invoked inter-area oscillation at 0.3 Hz frequency, which was sufficient for damping verification. In each test the peak of the first swing was approximately 20 mHz. Comparing the results showed that the amplitude of the first swing was very similar, but differences could be observed already during the second half of the first period of the oscillations. The lower peak amplitude of oscillation was only -10 mHz with POD controls whereas while operating in the reactive power or the voltage control modes, the corresponding amplitude was -15 mHz. In the POD control mode, the level of 0.3 Hz oscillations decreased below the peakto-peak amplitude of 10 mHz after approximately two periods of 0.3 Hz oscillations. The same level of oscillation was reached in voltage control mode within four periods of oscillation and in reactive power control mode within seven periods of oscillations. A future-proof SVC Based on these tests, the KA SVC has a significant positive effect on the damping of 0.3 Hz in inter-area oscillations. The test results can be applied as a basis to modify the controls in case there is a need to retune them to adapt to possible future structure changes in the transmission network. The SVC has shown that it increases the operational safety margin, thus ensuring high attenuation of inter-area oscillations even under heavy power transfer conditions. This is likely to become even more important in the coming decades. As networks expand, for instance with the installation of new, large generating units and large-scale wind power, they will become more complicated to manage and the potential for disruption will increase. To maintain high operational reliability and to enhance transmission capacity, including cross-border flows after the addition of new generating capacity, the Finnish transmission network has been reinforced with new transmission lines, series compensation, HVDC connections and SVC. Halonen is confident that Alstom Grid’s SVC solution can efficiently support the network. “Thanks to its high degree of redundancy and the robustness of the design, the SVC will improve the operational safety margin even in the most difficult system operating conditions and support system stability under system disturbances.” The cooling system and thyristor valve.­ 40 Alstom Grid///Spring-Summer 2011 Pauli Halonen Versatile SVCs Static VAr Compensators are used in both industrial and electric utility applications. Industrial SVCs are designed to compensate reactive power, stabilise voltage and filter harmonic currents from industrial loads. Typical applications can be found in the steel industry. As they improve the power quality, the end-user production increases, the total power losses are reduced and reactive power penalties are avoided. Utility SVCs are typically installed in the utility networks to support system voltage and to provide reactive power locally. This results in increased power transfer capacity and voltage stability. Increasingly, utility SVCs will also contribute to power oscillation damping in the electric networks. A prime example is the location of the Kangasala SVC right in the middle of the generation area of southern Finland. Allocating the whole 200 MVAr (ind)/240 MVAr (cap) capacity for power oscillation damping means that the effect of the SVC on damping inter-area electromechanical oscillations is quite significant.