Lens gaskets - kempchen.de

advertisement

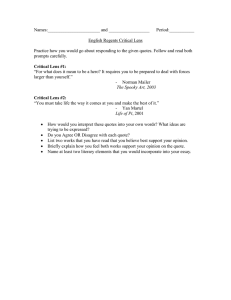

Lens gaskets The proven high-pressure gaskets Lens gaskets are reusable, as the sealing effect is generally achieved by elastic deformation of the surfaces. We can also specially produce bellows lenses, lens blind spectacle gaskets and half-lenses. The projected sealing width bG is calculated in relation to the angle a, which forms the sealing surface against the direction of the force (tubular axis) depending on the E modulus EG and the surface pressure exerted by bG = 100 · σ / EG · r · sinα. Lens blind spectacle gaskets are made of a sealing lens and a lens blind, which are connected by a ligament. It is also usual to use lens blinds on their own. In this case, it is useful to weld on a small plate to render the lens blind distinguishable. Gasket profiles Profile Profile A5BS Specify DN, PN, size a and d when ordering Cross-section A5 06 A5S A5BS Lens gaskets are impervious to overpressure. With increasing loads, the contact surface between the spherical lens surface and the spherical flange groove increases, so that the surface pressure only increases to a lesser extent. A disadvantage with standard sealing lenses is that, at high pressures and temperatures, the sealing lens can bulge along the circumference and weaken the tension of the connection. Also, at greater nominal diameter, the flange can become stuck in the area of the raised face diameter d5 and lift up at the sealing diameter. Steel type designation Material number For circulatory temperatures Code designation on the outer edge S235JRG2 P265GH 16Mo3 13CrMo4-5 10CrMo9-10 X6CrNiTi18-10 12CrMo19-5 1.0038 1.0425 1.5415 1.7335 1.7380 1.4541 1.7362 to 425 0C to 425 0C 425 to 475 425 to 520 520 to 580 350 to 550 max. 650 0C none none 1 Punch mark 2 Punch marks 3 Punch marks 4 Punch marks 1 notch X6CrNiMoTi17-12-2 1.4571 max. 550 0C 3 notches Further technical data see section “Materials commonly used”. µm Surface pressure limits for 20 °C N/mm2 N/mm2 E modulus at 20 °C kN/mm2 2 Surface pressure limits for 300 °C N/mm N/mm2 E modulus at 300 °C kN/mm2 Steel St 35 copper-plated Stainless steel 1.4828 3,2 6,3 1,6 3,2 1,6 3,2 3,2 6,3 6,3 12,5 3,2 6,3 3,2 6,3 σv σϑ 235 525 300 675 400 900 335 750 400 900 135 600 100 750 135 300 260 660 210 210 210 200 200 210 200 128 178 235 315 300 585 400 730 335 630 400 750 135 390 100 630 135 150 260 650 185 185 190 186 186 185 186 114 175 σv σϑ Kempchen Dichtungstechnik GmbH · Tel. +49 (0)208 8482 0 · Fax. +49 (0)208 8482 285 · info@kempchen.de · www.kempchen.de 88 Lens gaskets Monel 2.4360 3,2 6,3 Steel 1.4541 silver-plated Heatresistant mild steel 1.7362 3,2 6,3 Iron 1.1003 from to Materials Recommended max. roughness of the flange surfaces Stainless steel 1.4541 A5, A5S, A5BS Heat-resistant mild steel 1.5415 Profile Copper 2.0090 Gasket limiting values Lens gaskets The proven high-pressure gaskets DN d1 d2 50 65 80 100 125 150 200 55 70 82 107 131 158 205 78 102 116 143 180 210 276 10 15 25 40 50 65 80 100 125 150 200 43 54 69 81 105 128 155 200 62 78 102 116 143 180 210 276 d5 PN 63 68 85 97 127 157 183 243 PN 100 55 68 85 97 127 157 183 243 PN 160 Lens gaskets for flange connections PN 63 to PN 400 h r x 13,6 18,3 18,3 22,1 31,2 34,9 40,5 90 113 131 171 210 249 327 9 13 13 15 22 26 27 12,2 13,9 18,7 18,7 22,8 32,3 36,0 42,2 71 89 112 130 169 208 146 323 8 9 13 13 15 22 26 27 10 15 25 40 50 65 80 100 125 150 175 200 42 53 67 77 99 120 144 166 188 62 78 102 116 143 180 210 243 276 55 68 85 97 127 157 183 218 243 PN 250 12,6 14,3 19,4 20,1 24,8 35,0 39,7 39,2 44,3 70 88 110 127 165 202 239 280 314 8 9 13 13 15 22 26 21 25 15 25 40 50 65 80 100 125 150 200 27 39 48 61 80 99 121 143 195 43 62 78 102 116 143 180 210 276 39 55 68 85 97 127 157 183 243 PN 320 10,2 13,6 15,9 21,4 19,0 24,8 34,6 40,1 41,9 48 68 85 106 129 165 203 238 320 6 8 9 13 13 15 22 26 25 27 39 55 68 85 97 157 183 218 243 PN 400 10,0 11,1 14,5 16,0 19,3 20,1 31,9 39,7 39,9 45,3 10 15 25 40 50 65 80 125 150 175 200 10 15 25 40 50 65 80 100 125 150 200 („a“)* DIN 2696 : 1999-08, Series 1 06 Conforms to DIN 2696 : 1999-08* Ordering example for a lens gasket, DN 100, PN 63, conforming to DIN 2696, made of ...1): Lens gasket, DN 100, PN 63, DIN 2696 Series 1 / 1.7335 15 24 36 48 67 77 129 144 164 185 41 52 70 80 96 134 150 193 28 43 62 78 102 116 180 210 243 276 62 78 102 116 143 180 210 276 55 68 85 97 127 157 183 243 12,9 14,6 18,3 19,0 25,9 30,2 37,7 42,6 31 46 66 84 111 127 209 239 279 312 70 87 113 129 162 212 243 319 6 6 8 9 13 13 22 26 21 25 8 9 13 13 15 22 26 25 DIN 2696 : 1999-08, Series 2 DN d1 d2 d5 PN 63 68 127 157 183 PN 100 h r x 14,6 24,5 33,6 38,4 87 166 205 242 9 15 22 26 50 100 125 150 52 100 124 148 78 143 180 210 10 15 25 40 50 100 125 150 25 39 51 98 121 145 43 62 78 143 180 210 39 55 68 127 157 183 PN 160 10,8 13,6 14,9 25,2 34,6 39,4 47 68 87 164 203 240 6 8 9 15 22 26 10 15 25 40 50 100 125 150 25 38 49 92 113 134 43 62 78 143 180 210 10,8 13,9 15,6 27,2 37,3 43,1 46 67 86 160 197 232 6 8 9 15 22 26 15 25 40 50 15 23 35 45 28 43 62 78 10,0 11,4 14,9 16,9 31 45 65 82 6 6 8 9 10 15 25 40 100 125 9 14 20 32 101 119 21 28 43 62 143 180 39 55 68 127 157 183 PN 250 27 39 55 68 PN 320 18 27 39 55 127 157 9,0 10,3 12,3 15,7 24,2 35,3 20 30 43 64 167 202 6 6 6 8 15 22 Dimensions in mm 1) Specify material when placing order * Sealing lenses with dimensions conforming to with DIN 2696 April 1972 edition must always be arranged in advance. To avoid misunderstandings the desired sealing lens height “a” should always be given for the internal diameter d1 specified. Dimensions in mm Kempchen Dichtungstechnik GmbH · Tel. +49 (0)208 8482 0 · Fax. +49 (0)208 8482 285 · info@kempchen.de · www.kempchen.de Lens gaskets 89 Lens gaskets The proven high-pressure gaskets Lens gaskets for flange connections PN 63 to PN 400 06 Works standard 1082) Ordering example for a lens gasket with d1=94 mm internal diameter and d2 = 143 mm external diameter, made of ...1): Lens gasket 94x143 WN 108 / 1.7335 Works standard 108 DN d1,min* hmax d1,max* hmin d2* r* d5* x* 25 32 50 70 88 112 129 170 218 250 18 27 39 55 68 85 97 127 157 183 5,7 6,0 6,0 8,0 9,0 13,0 13,0 15,0 22,0 26,0 218 243 298 345 394 445 28,0 27,0 25,0 26,0 23,0 24,0 218 243 298 345 21,0 25,0 25,0 30,0 PN 63 to PN 400 10 15 25 40 50 65 80 100 125 150 10 14 20 34 46 62 72 94 116 139 8,0 10,0 11,5 15,0 16,5 21,0 21,5 26,0 35,5 41,0 14 18 29 43 55 70 82 108 135 158 (175) 200 250 300 350 400 176 198 246 295 330 385 42,5 42,5 43,0 43,5 45,5 45,5 183 206 257 305 348 395 (175) 200 250 300 162 183 230 278 40,0 45,5 48,0 53,0 177 200 246 285 7,0 21 9,0 28 9,5 43 12,5 62 13,5 78 18,5 102 18,5 116 22,0 143 29,5 180 35,0 210 PN 63 to PN 100 40,5 40,0 39,5 40,5 39,5 42,0 243 276 332 385 425 475 296 329 406 473 538 610 PN 160 to PN 400 35,5 40,0 43,0 51,0 243 276 332 385 296 329 406 473 Dimensions in mm 1) Specify material when placing order 2) Unless otherwise agreed, the sealing lenses will be supplied with d1,min and hmax. The interior diameters should be adapted to the by boring of the integral or collar flanges. * In accordance with DIN 2696 April 1972. Kempchen Dichtungstechnik GmbH · Tel. +49 (0)208 8482 0 · Fax. +49 (0)208 8482 285 · info@kempchen.de · www.kempchen.de 90 Lens gaskets