Facts on File

How humidity and temperature affect

release performance

Release performance is affected by a very large number of potential variables, including humidity

and temperature.

Humidity and substrate stiffness

Substrate basis weight, and subsequent stiffness, is a major variable in the practical control of

release performance. A major influence on stiffness of paper substrates, which are by far the major

proportion of the market, is humidity.

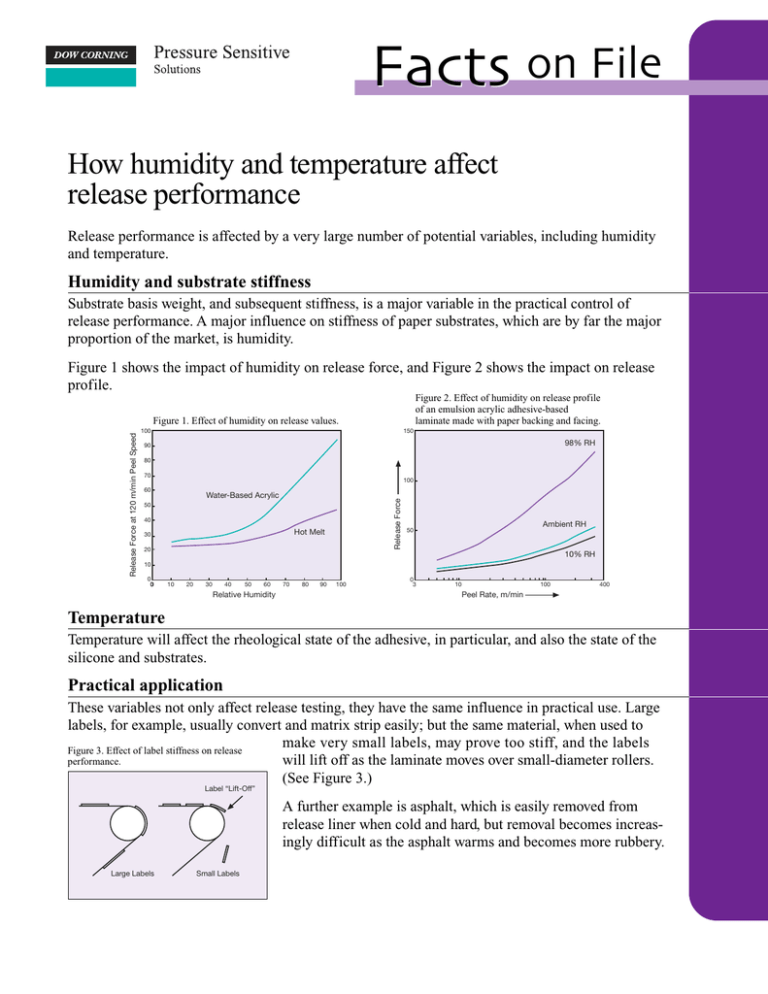

Figure 1 shows the impact of humidity on release force, and Figure 2 shows the impact on release

profile.

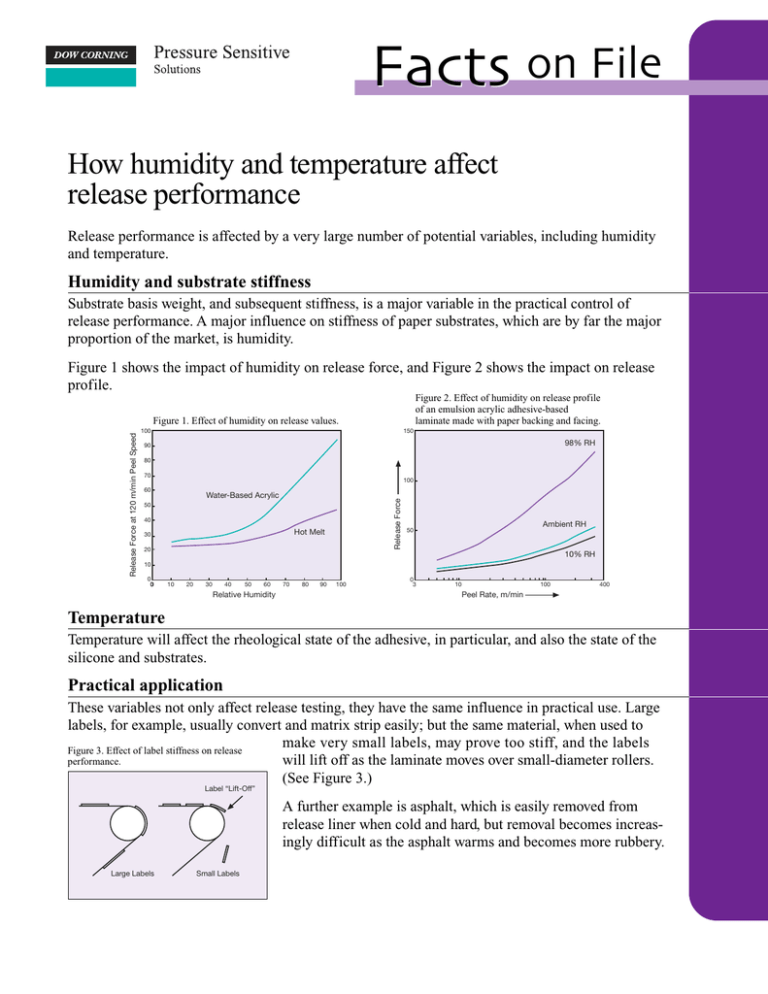

Figure 2. Effect of humidity on release profile

of an emulsion acrylic adhesive-based

laminate made with paper backing and facing.

150

98% RH

90

80

70

100

60

Water-Based Acrylic

Release Force

Release Force at 120 m/min Peel Speed

Figure 1. Effect of humidity on release values.

100

50

40

Hot Melt

30

20

Ambient RH

50

10% RH

10

0

0

10

20

30

40

50

60

Relative Humidity

70

80

90

100

0

3

10

100

400

Peel Rate, m/min

Temperature

Temperature will affect the rheological state of the adhesive, in particular, and also the state of the

silicone and substrates.

Practical application

These variables not only affect release testing, they have the same influence in practical use. Large

labels, for example, usually convert and matrix strip easily; but the same material, when used to

make very small labels, may prove too stiff, and the labels

Figure 3. Effect of label stiffness on release

performance.

will lift off as the laminate moves over small-diameter rollers.

(See Figure 3.)

Label “Lift-Off”

A further example is asphalt, which is easily removed from

release liner when cold and hard, but removal becomes increasingly difficult as the asphalt warms and becomes more rubbery.

Large Labels

Small Labels

For troubleshooting assistance

Contact your Dow Corning technical representative or email paper.industry@dowcorning.com.

For pressure sensitive product and service information

Visit www.dowcorning.com/psi. For easy future reference, bookmark the page and add it to your

list of “Favorites.”

We’re here to help

Whether you are trying to solve a problem, improve your profits or take advantage of a new

opportunity, the Dow Corning team can help … with solutions, capabilities and choices you may

never have imagined.

Dow Corning is more than materials and more than silicones. We are also process optimizers, cost

reducers, custom formulators, applications engineers, technology innovators, productivity experts,

global market expanders and more.

Let us put our innovative thinking to work for you.

Dow Corning is a registered trademark of Dow Corning Corporation.

We help you invent the future is a trademark of Dow Corning Corporation.

©2004 Dow Corning Corporation. All rights reserved.

Printed in USA

AGP6909f

Form No. 30-1110A-01