Chemical Engineering and Processing 43 (2004) 1211–1222

Mixing of complex fluids with flat-bladed impellers: effect of impeller

geometry and highly shear-thinning behavior

Rajeev K. Thakur, Ch. Vial1 , G. Djelveh∗ , M. Labbafi

Laboratoire de Génie Chimique et Biochimique, Université Blaise Pascal, 24 Avenue des Landais, BP 206, F-63174 Aubiere Cedex, France

Received 25 June 2003; received in revised form 14 November 2003; accepted 14 November 2003

Available online 13 January 2004

Abstract

Mixing of rheological complex fluids was investigated using flat-bladed impellers as close-clearance agitators in the laminar regime. Two

Newtonian and six highly shear-thinning fluids were used. The non-Newtonian fluids were adequately described by a power-law model with a

flow index n between 0.1 and 0.4. Power draw analysis was used to explore the combined influence of pseudoplasticity and impeller geometry.

Geometry was studied first by varying the column-to-impeller diameter ratio, and then by combining several similar mixing elements on the

same shaft. For pseudoplastic fluid, the Rieger–Novak and the power curve methods as well as an original Couette analogy were used for

estimating the effective shear rate and the proportionality constant KS . A good agreement was obtained between these three methods. KS

was shown to be nearly independent of n: the Metzner–Otto assumption was shown to be valid for all the geometries studied. A generalized

dimensionless power draw curve which took pseudoplasticity into account was obtained by shifting the non-Newtonian results to the Newtonian

curve. The effectiveness of flat-bladed impellers for dispersive mixing in complex fluids proved in previous works was explained by the fact

that the effective shear rate remained high even when power consumption dramatically decreased with n.

© 2003 Elsevier B.V. All rights reserved.

Keywords: Non-Newtonian mixing; Effective shear rate; Flat-bladed impeller; Power consumption; Shear-thinning fluids

1. Introduction

Mechanically stirred vessels are commonly used in the

process industries to fulfill a large variety of tasks, including the classical mixing of miscible fluids in single-phase

flows (distributive mixing), but also powder dispersion or

solid blending, dispersion of an immiscible liquid phase for

mass transfer or emulsification, gas dispersion into a continuous liquid phase for mass transfer or sometimes in order

to form foams in food industries. Mixing operations involving several phases are generally referred to as dispersive

mixing. Chemical engineers and food processors often deal

with complex fluids in the laminar regime which are usually highly viscous and shear-thinning, sometimes exhibiting a highly viscoelastic behavior. It is clear that both vessel

shape and impeller design have to be adapted to take these

∗ Corresponding author. Tel.: +33-473-405-055;

fax: +33-473-407-829.

E-mail addresses: christophe.vial@univ-bpclermont.fr (Ch. Vial),

djelveh@gecbio.univ-bpclermont.fr (G. Djelveh).

1 Tel.: +33-473-405-266; fax: +33-473-407-829.

0255-2701/$ – see front matter © 2003 Elsevier B.V. All rights reserved.

doi:10.1016/j.cep.2003.11.005

properties into account, for distributive as well as for dispersive mixing. Generally, close-clearance impellers such as

anchors, helical screws or helical ribbons, are recommended

for mixing highly viscous non-Newtonian fluids as the most

effective mixers. However, such impellers, for example helical ribbons, are sensitive to highly shear-thinning behavior

which reduces their mixing effectiveness [1]. Similarly, for

gas dispersion in such fluids, their effectiveness remains unfortunately low. As an illustration, for foaming process in

food industries, an ideal mixer should promote gas dispersion and at the same time mix the fluid efficiently to favor

a rapid mixing and diffusion of proteins and surfactants to

the gas–liquid interfaces. Up to now, there is no definitive

answer to the problem of gas dispersion in highly viscous

fluids. Although combinations of conventional geometries

have been suggested a priori as potential solutions, e.g. by

combining a helical ribbon and a Rushton turbine [2], gas

dispersion in highly viscous fluids remains an open question.

This is the reason why, in the process industries, gas dispersion in complex fluids is generally carried out in mixing

units that not necessarily the most adequate, but are generally more effective than conventional mixing tanks equipped

1212

R.K. Thakur et al. / Chemical Engineering and Processing 43 (2004) 1211–1222

with ribbons or anchors. These units can be divided into two

groups. The first group consists of rotor–stator units using

a large solid rotor generally equipped with pins, as well as

a narrow gap between rotor and stator, the size of which

is around a few millimeters or may be lower. These rotors

are driven at high rotational speed, generally between 1000

and 10,000 rpm [3]. The second group is characterized by

scraping agitators and corresponds to scraped surface heat

exchangers. Such mixing units can be operated using either

large solid or small open (i.e. small volume) rotors, both

equipped with scraping blades [4,5], but rotational speed is

generally lower than 1000 rpm for practical applications.

Even though both groups of mixing units are widely used in

the industry, they present a high power consumption level

and were not originally designed for gas dispersion.

Recently, Thakur et al. [6] proved that open non-scraping

impellers favor gas dispersion even at low rotational speed,

requiring a fairly low level of energy consumption to make

food foams, as compared to solid rotors. The characteristics

of impellers that have to be preferred for gas dispersion

non-Newtonian viscous fluids are therefore:

• a small gap between blades and wall (close-clearance);

• a small volume (open) rotor that favors backmixing, increasing bubble residence time;

• blades without holes that enforce the fluid to move through

the gap.

Their results proved that large rotors and high-speed rotating impellers are not necessary to form small bubbles,

while scraping devices are needed only when heat transfer at the wall is the limiting step, for example, for freezing in ice cream manufacturing. In other cases, the authors

recommended flat-bladed impellers that fulfill all the conditions mentioned above. Flat-bladed impellers have been

already used for a wide range of industrial processes, for

example, for mixing of powders [7], but generally not as

close-clearance agitators. They constitute one of the simplest

types of mixing elements. However, even for such simple

systems, the literature contains only sketchy information at

best, both in single-phase and multiphase flows.

The goal of this paper is to analyze the mixing processes

in terms of power consumption in laminar mixing region.

This approach affords an estimation of shear rate as a function of geometry of impeller, rotation speed and fluid properties that can be used for scale-up purpose. Geometry is

investigated using both the combination of several similar

mixing elements and the column-to-impeller diameter ratio on the basis of power consumption measurements. Experiments are also used to gain insight into the role played

by pseudoplasticity and viscoelasticity, especially to estimate the deviations from the Newtonian power input when

highly shear-thinning fluids are involved. The influence of

pseudoplasticity is analyzed using the classical approaches

found in the literature, such as Metzner–Otto concept [8],

Rieger–Novak method [9] and a Couette analogy developed

in this work.

Le

ne=2

(a)

D

DC

ne=3

(b)

Fig. 1. Description of mixing unit (a) and impeller geometry (b).

2. Materials and methods

2.1. Experimental set-up

The mechanically stirred column used in this work is similar to that in [6] for their experimental study. The inner

column diameter DC is 35 mm for a total column length

of 440 mm. Rotational speed N of impeller can be varied from 100 to 1500 rpm using a speed-controlled engine

(IK LaborTechnik RE-16 from Ikavisk, Germany). A stress

gauge torquemeter (IK MR-D1 from Ikavisk) enables the

measurement of the torque (T) on the shaft of the impeller up

to 1 N m with an accuracy of 0.5% full scale. Torque measurements have been validated using concentric cylinders of

25, 30 and 33 mm diameter respectively. Column temperature can be controlled to maintain constant rheological properties using a water circulation in the jacket around the column. All experiments have been conducted at 25 ◦ C. Mixing has been carried out using flat-bladed elements formed

by four right-angle paddles, the diameters (D) were 22, 28

and 33 mm, which corresponds column-to-impeller distance

of 6.5, 3.5 and 1.0 mm respectively. Element length (Le ) is

always 65 mm. The agitators used in this work were formed

either with ne = 2 or 3 consecutive identical elements, as

shown in Fig. 1. This figure summarizes the geometrical

characteristics of an element and shows how they are located

in the column. The detailed specifications of the impellers

used in this work are reported in Table 1. As preliminary

Table 1

Description of the impellers used in this work

Abbreviation

FB-33-3

FB-28-3

FB-28-2

FB-22-3

FB-22-2

Geometrical characteristics of the impellers

D (m)

D/DC

Le (m)

ne

0.033

0.028

0.028

0.022

0.022

0.94

0.80

0.80

0.63

0.63

0.065

0.065

0.065

0.065

0.065

3

3

2

3

2

R.K. Thakur et al. / Chemical Engineering and Processing 43 (2004) 1211–1222

experiments had proved that there was no difference between

torque measurements in the batch and the continuous mode,

measurements were conducted only in the batch mode. This

was probably due to the low flow rate values generally used

in such units, with a mean residence time usually between

5 and 10 min.

2.2. Fluids and rheology

Two Newtonian fluids and six highly shear-thinning fluids have been prepared for this work. Steady shear viscosity

as well as primary normal stress difference were measured

using a stress-controlled rheometer (SR-5 from Rheometric ScientificTM , USA) equipped with a Peltier circulator

for temperature control. Newtonian fluids include pure and

aqueous solutions of glycerol denoted GLY (Acros Organics, USA), as well as a solution of polyalkylene glycol polymers (Emkarox HV45 from Uniquema, The Netherlands)

denoted HV45. For non-Newtonian fluids, the study focuses

on highly shear-thinning fluids that can be adequately fitted

using a power-law model with a flow index n between 0.10

and 0.40. In this case, shear stress τ can be related to shear

rate γ̇ using the following equation where k is the consistency factor:

τ = kγ̇ n

(1)

Emulsions denoted E1, E2 and E3 are three model food

emulsions. They have similar components as the model

emulsion used in a previous work [6], but the amount of

fats and starch differs between E1, E2 and E3 to modify

their rheological properties. The three other shear-thinning

fluids are a 2% xanthan aqueous solution (XAN), a 2% guar

aqueous solution (GUA) and a polyacrylamide aqueous

solution (PAA).

Fluid properties have been measured at the temperature

used for mixing experiments, i.e. 25 ◦ C. At this temperature, all fluids can be adequately described by a two

parameter power-law model in the range of shear rate studied in this work. However, non-Newtonian fluids can be

divided into two classes depending on either they exhibit a

measurable primary normal stress difference N1 or only a

1213

shear-dependent viscosity. In this study, only PAA presents

non-negligible viscoelastic properties when the shear rate is

higher than 100 s−1 . In this case, the primary normal stress

difference has been fitted using a power-law model too:

N1 = pγ̇ q

(2)

Finally, the resulting values obtained by linear regression of

power-law parameters for shear viscosity, primary normal

difference as well as Newtonian viscosity are reported in

Table 2.

3. Results and discussion

3.1. Newtonian power input

Power consumption for Newtonian fluids is usually expressed by the dimensionless power number NP as a function of the rotational Reynolds number Re when no vortex is

present. This procedure provides a single master curve that

depends only on impeller geometry and can be used to predict power requirements for any given fluid properties (density ρ and viscosity µ), impeller dimensions and rotational

speed. In the laminar regime, the quantity KP is defined as

follows:

NP Re = KP

(3)

KP should be only a function of impeller geometry for

any Newtonian fluid. A significant deviation from Eq. (3)

may be used to detect the end of the laminar mixing

region.

In this work, torque data obtained with GLY and HV45

as Newtonian fluids have been transformed into power input

using the classical dimensionless form of NP for all the impellers (see e.g. [10,11]). The results have been expressed as

a function of Re in order to obtain the master curve NP versus

Re. For each impeller, KP has been estimated by performing

a regression analysis on the power curve data. Experimental results confirm that the laminar regime prevails inside

the column up to about Re ≈ 30 according to Eq. (3). As

expected, power consumption increases both with impeller

Table 2

Description of the fluids used in this work

Abbreviation

GLY

HV45

PAA

E1

E2

E3

XAN

GUA

Rheological properties of the fluids

k (Pa sn )

n

Shear rate (s−1 )

p (Pa sq )

q

Shear rate (s−1 )

0.78

3.78

52.7

110

130

152

11.2

124

1

1

0.4

0.26

0.27

0.31

0.18

0.12

0.1–1000

0.1–1000

10–1000

0.1–1000

0.1–1000

0.1–1000

0.1–1000

1–500

–

–

94.8

–

–

–

–

–

–

–

0.62

–

–

–

–

–

–

–

100–1000

–

–

–

–

–

1214

R.K. Thakur et al. / Chemical Engineering and Processing 43 (2004) 1211–1222

Power number NP

10000

1000

100

10

HV45

GLY

Eq. (4)

1

0.1

1

10

100

Re

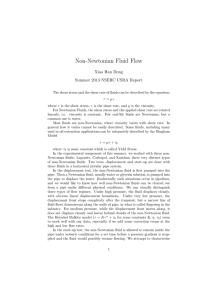

Fig. 2. Example of power data for Newtonian fluids (FB-28-3).

diameter D and element number ne . KP is shown to be nearly

proportional to the number of elements, which proves that

there is no significant interaction between them. For all the

impeller geometries used in this work, a regression analysis

on KP data provides the following correlation in the laminar

regime:

ne Le

DC − D −0.42

KP = 164.8

(4)

D

D

Fig. 2 illustrates the typical Newtonian power consumption

behavior depicted by Eq. (3) for impeller FB-28-3 and also

includes the calculated NP versus Re curve obtained using

the estimation of KP from Eq. (4). As can be seen, there is a

good agreement between predictions and experimental data.

As indicated above for scale-up purpose it is usual to represent the mixing efficiency of any impeller by postulating

a relationship between an effective shear rate γ̇a around the

impeller and rotational speed [1]:

γ̇a = KS N

(5)

KS is the proportionality constant and is a priori a function

of fluid properties. For example, it may depend on the flow

index and be expressed as KS (n). But ideally, KS is a constant that should be insensitive to the rheological properties

of the fluids in the laminar regime for any given impeller

geometry. This assumption is the basis of the Metzner–Otto

concept [8] which is still extensively used for scale-up purpose in the process industry when engineers have to deal

with non-Newtonian media [12]. As an illustration, most

conventional viscosimetry techniques used for chemical, biological or food media result directly from the application

of this concept [13,14]. The conventional methods for KS

determination that have been developed in the literature are

summarized in [14], but are also described in Section 3.2.

With these methods, KS cannot be found using only Newtonian fluids, but its estimation generally requires duplicate

power consumption measurements using both Newtonian

and non-Newtonian fluids in order to modify n. KS values

obtained for non-Newtonian fluids may depend on n and

must be noted KS (n), while the Newtonian fluids are generally used as a reference. Conversely, we propose here to

develop a specific method in order to estimate KS using only

Newtonian fluids. Such values will be noted KS (n = 1). As

this method is original, one of the objectives of this paper

will also be to check whether there is a compatibility between KS (n = 1) and KS (n) values obtained by conventional

methods.

The classical Couette analogy consists in determining the

equivalent diameter D∗ of a cylinder that exhibits a power

consumption equal to that of the impeller as a function of

rotational speed [15]. However, D∗ is a function of fluid

properties: for power-law fluids, it is a function of flow

index D∗ (n). Carreau and coworkers [15] showed that D∗

varies only slightly with n for helical ribbon impellers, which

should correspond to a KS value nearly independent of n

[1]. However, this method still requires torque measurements using both Newtonian and non-Newtonian fluids. In

the modified method that is suggested here, one looks for a

two-parameter model using only the Newtonian power input data: the first one is D∗ = D∗ (n = 1), while the second

is a radial coordinate ro in the Couette geometry for which

the shear rate depends slightly on n.

For any power-law fluid, the shear rate in a Couette geometry of internal diameter D∗ and external diameter DC can

be estimated as a function of n, N and the radial coordinate

r using:

∗ 2/n −1

4πN D∗ 2/n

D

(6)

γ̇(r, n) =

1−

n

2r

DC

A relation between D∗ and DC can be deduced by evaluating

shear rate from Eq. (6) when r = DC /2, injecting Eq. (1)

and using the torque balance in a Couette geometry. Details

of the calculations are reported in Appendix A. The result

corresponds to Eq. (7):

−n/2

2 1/n

πkn

L

D

4πN

e e C

D∗ = DC 1 +

(7)

n

2T

As a first approximation, D∗ can be considered to be independent of n and can be estimated using power input data

obtained with the Newtonian fluids only. Using the Newtonian and non-Newtonian test fluids as well as Eq. (7), Table 3

confirms that D∗ is experimentally a weak function of n for

flat-bladed impellers. Experimental results also show that

D∗ is always close to D, as D∗ /D remains between 0.94

and 0.98 in this work. Furthermore, D∗ appears to tend to

D when the ratio D/DC decreases. Using again Eq. (6), it is

R.K. Thakur et al. / Chemical Engineering and Processing 43 (2004) 1211–1222

Fluid

D∗ (m)

GLY

HV45

PAA

E1

E2

E3

XAN

GUA

0.031

0.031

0.030

0.031

0.032

0.032

0.031

0.031

possible to show that there is a radial coordinate for which

γ̇/N is nearly independent of n:

n = 0.1

n = 0.2

n = 0.4

n = 0.6

n = 0.8

n = 1.0

1200

800

400

(8)

The existence of ro needs that the following condition is

fulfilled:

D∗ ≤ 2ro ≤ DC

1600

0

0.031

0.032

0.033

(9)

Note that a roughly similar method was used recently by

Chavez-Montes et al. [16] for other impeller geometries in

order to measure the apparent viscosity. However, their analysis needs to collect torque data on the external cylinder

of their tank, which limits the applicability of their results

to batch units based on the principle of a strain-controlled

rheometer. By contrast, the model developed here correspond to the most common situation when torque data are

collected on the shaft of the impeller, which enables their

application to any impeller-driven system equipped with a

torquemeter, regardless of its dimension and location, either

in the batch or the continuous mode.

The parameter ro of Eq. (8) can be found by minimizing

the function f(r) defined by Eq. (10) using a least-square

Levenberg–Marquardt algorithm for n between 0.1 and 1,

which corresponds to the flow index of the fluids used in

this work:

1 f(r) =

[γ̇(r, i) − γ̇(r, 1)]2

(10)

N

0.034

2⋅r (m)

Fig. 3. Radial evolution of shear rate in the Couette geometry as a

function of fluid properties for impeller FB-33-3 between D∗ = 0.031 m

and DC = 0.035 m.

γ̇(ro , n) and γ̇(ro , 1) is less than ±2% for FB-33-3 and less

than ±4% for FB-28-2 and FB-28-3, but it is a around ±7%

for FB-22-2 and FB-22-3: as expected, shear rate deviates

from the Couette model when clearance increases. The good

agreement obtained with FB-33-3 is illustrated by Fig. 4

γ⋅ (r0 ,n

600

500

+3%

400

-3%

0.1≤i≤1

300

n=0.8

n=0.6

n=0.4

200

n=0.2

n=0.1

100

0

0

100

200

300

γ⋅ (ro ,1

400

500

600

(

The optimization procedure shows that ro always exists for

any flat-bladed impeller used here. As an illustration, calculated γ̇(r, n) values are presented in Fig. 3 at a given rotational speed as a function of r and n for impeller FB-33-3.

This figure confirms graphically the existence of a unique radial coordinate ro between D∗ /2 and DC /2 (around 0.0162 m)

for which γ̇ is nearly independent of n for this impeller.

Results from the optimization procedure show that ro increases when D increases. Similarly, the ratio 2ro /D tends to

1 when D increases. The difference in ro observed respectively between FB-28-2 and FB-28-3, as well as between

FB-22-2 and FB-22-3 are less than 1%, which proves that

ro is clearly insensitive to ne . The relative deviation between

0.035

(

∀N,

γ̇(ro , n)

γ̇(ro )

γ̇(ro , 1)

≈

=

N

N

N

γ⋅(r ,n

(

Table 3

Estimation of the equivalent diameter D∗ of a virtual Couette geometry

from experimental data (Eq. (7)) for impeller FB-33-3 as a function of

fluid properties

1215

Fig. 4. Comparison of γ̇(ro , n) and γ̇(ro , 1) values for FB-33-3 at the

same rotational speed.

1216

R.K. Thakur et al. / Chemical Engineering and Processing 43 (2004) 1211–1222

Table 4

Comparison of Couette analogy, slope and power curve method for KS

estimation

KS values

Couette (Eq. (11))

Slope method

PAA∗

E1∗

E2∗

E3∗

XAN∗

GUA∗

FB-33-3

FB-28-3

FB-28-2

FB-22-3

FB-22-2

51.9

51.6

71.0

49.2

43.5

52.3

59.5

51.6

27.3

30.4

28.5

30.3

27.8

×

30.0

42.8

27.2

29.7

×

29.0

×

29.3

–

28.2

16.0

19.0

–

18.5

18.9

17.8

–

–

16.0

18.3

×

–

–

17.4

–

–

(*) From the power curve method (Eq. (13)); (×) not in the experimental

design; (–) accurate estimation of KS not possible.

which plots γ̇(ro , n) as a function of γ̇(ro , 1) at the same

rotational speed. When ro has been found, a linear relation

between γ̇(ro ) and N can be obtained. Using Eq. (6), this

relation is valid for any n value between 0.1 and 1:

∗ 2 ∗ 2 −1

D

D

γ̇(ro ) = 4π

1−

N = KS N

(11)

2r0

DC

A comparison with Eq. (5) shows that if the Metzner–Otto

concept is valid for the impeller used here, the KS values

obtained from Eq. (11) should be at least proportional to

that of Metzner–Otto. In term of compatibility between both

methods, the ideal situation should be that both would be

equal.

KS values obtained using the Couette analogy have been

reported in Table 4. The data show that the number of elements is of little influence on KS , while KS increases drastically as clearance decreases. These results were expected:

with flat-bladed impellers, shear rate is mainly controlled

by the gap size as far as the ratio Le /DC is high enough to

overshadow the end effects, which is the case here. As a

result, the only key parameter is the ratio D/DC . The steep

increase in KS with D/DC could not be fitted using a simple

power-law relation, but the following expression has been

found:

D

KS (n = 1) = exp 3.25

+ 0.69

(12)

DC

Note that Eq. (12) has been obtained using only torque

data of Newtonian fluids. As a conclusion, flat-bladed impellers behave nearly as ideal impellers with Newtonian fluids: power consumption is proportional to impeller length

when ne Le D and KS depends only on clearance.

3.2. Influence of shear-thinning behavior

The influence of pseudoplasticty on power consumption

can be analyzed using the Metzner–Otto concept. As already

mentioned, this approach is based on Eq. (5) as an empirical assumption. Although Metzner–Otto assumed that KS

was a proportionality constant independent of the rheolog-

ical properties of the fluid, many authors have doubted as

to whether this is true for highly shear-thinning fluids. Despite a recent contribution based on CFD that attended to

give a theoretical support and to highlight the limitations of

Metzner–Otto concept for anchor impellers [17], its applicability still remains questionable for many mixing devices, as

KS often appears to be a function of flow index for power-law

fluids. As an illustrations, several authors [1,18] reported a

strong dependence of KS on n for highly shear-thinning fluids using helical ribbons. This trend was confirmed for other

types of impellers: for example, a strong evolution of KS

with n at very low rotational speed (<10 rpm) was observed

with flag impellers [19]. Nevertheless, empirical KS values

are extensively tabulated for various mixers in the literature

and Metzner–Otto method is still recommended as a standard procedure for mixing analysis with close-clearance impellers in the laminar regime [12]. In this work, we will consider that the proportionality constant can be written KS (n)

and depends a priori on n.

The procedures used in the literature for KS (n) estimation, known as viscosity matching techniques, have been

summarized in [14], such as the power curve and the torque

curve method. The power curve method corresponds to

the most classical technique used in the literature. For any

non-Newtonian fluid, the average shear rate is calculated

from torque data using the following expression:

1/n−1

1

2πT

γ̇a =

= KS (n)N

(13)

k NKP D3

This expression can be deduced from Eq. (3) using the definitions of NP , Re and the fact that power on the shaft is

equal to the product 2πNT. The slope of the average shear

rate values versus N obtained by regression analysis gives

access to KS (n).

An alternative procedure, denoted sometimes as the slope

method, was also suggested by Rieger and Novak [9]. This

consists in plotting power number NP as a function of a

modified Reynolds number Rem defined as follows:

Rem =

ρN 2−n D2

k

(14)

Power consumption data can be used to estimate KP (n) values obtained from Eq. (14):

NP Rem =

2πT

= KP (n)

kNn D3

(15)

Considering γ̇a = (k/µ)1/n−1 , KS is deduced by combining

Eqs. (3), (5) and (15):

KP (n) 1/n−1

(16)

KS (n) =

KP

where KP is defined by Eq. (3) for Newtonian fluids. If KS

does not depend on n, the proportionality constant can be

obtained directly from the slope of the straight line resulting

from the plot of log(KP ) versus (1 − n). This justifies the

R.K. Thakur et al. / Chemical Engineering and Processing 43 (2004) 1211–1222

.

γ a s −1

( )

500

PAA

XAN

Couette

400

300

200

100

0

0

5

10

N (s-1)

15

20

Fig. 5. Typical KS determination from the power curve method and

comparison with the predicted curve using the KS value from the Couette

analogy (impeller FB-28-3).

name of “slope method”. Note that this method, unlike the

power curve method, assumes that the Metzner–Otto concept

is valid. To circumvent this limitation, it is possible to apply

directly Eq. (16) for estimating KS (n) when the applicability

of Eq. (5) is doubtful. This method will be referred to as the

direct calculation of KS (n).

KS was first determined for each non-Newtonian fluid using the power curve method (Eq. (13)). A typical plot for

KS determination on impeller FB-28-3 is reported in Fig. 5

for the 2% xanthan solution XAN and the polyacrylamide

solution PAA. This figure illustrates the results obtained for

all impellers: γ̇a is generally proportional to N for a certain

range of N values. In Fig. 5, the plot is nearly linear for

PAA up to N equal to 20 s−1 , but it deviates for XAN when

N is higher than 8 s−1 , which corresponds to the end of the

laminar region. This figure also shows the good agreement

between the values obtained from the power curve method

and the modified Couette analogy respectively for impeller

FB-28-3. KS (n) values for each impeller have been determined in this way for all the shear-thinning fluids. The results are reported in Table 4 and compared to those of the

Couette analogy. In this table, the symbol (–) represents the

experiments for which an accurate estimation of KS (n) could

not be obtained because the linear region was too short. This

may correspond either to the end of the laminar region or to

the limits of the power-law region, especially for PAA that

presents a Newtonian region when shear rate is lower than

1 s−1 followed by a transition region between 1 and 10 s−1 .

The results in Table 4 also show that KS (n) depends only

slightly on the element number ne and on the flow index

n, even for highly shear-thinning fluids. By contrast, the

dependence on D/DC appears to be strong for flat-bladed

1217

impellers, as expected. These results tend to prove that

the Metzner–Otto concept may be valid and that the slope

method could be applied. This also differs from recent

studies cited previously on helical ribbon impellers that

report a strong dependence on n for highly shear-thinning

fluids. There are however some punctual deviations. The

largest discrepancies are observed for PAA with impeller

FB-33-3 and for GUA with impeller FB-28-3. These will

be discussed later when both the slope method and the direct calculation of KS (n) will be compared. In Table 4, one

should also note that KS (n) values from the power curve

method are very close to that of the Couette analogy. These

results are in agreement with those presented in Fig. 5.

However, it appears that the power curve method generally

provides KS (n) values a bit higher, especially when clearance increases. The agreement between both methods can

however be considered as satisfactory if we consider that

the Couette analogy is based on power input data using only

Newtonian fluids, while the power curve method requires

additional experiments with non-Newtonian test fluids.

From experimental data, power number NP was plotted

versus Rem for all impellers. Results are reported in Fig. 6

for impeller FB-28-3. KP (n) values can be easily deduced

from these plots (Eq. (15)). As expected, the results show

that KP (n), and consequently power consumption, dramatically decrease when n decreases at a given Rem value. A

typical application of the slope method is reported in Fig. 7

for impeller FB-28-3: KP (n) has been plotted as a function of n − 1 using the data from both the Newtonian and

the non-Newtonian fluids. This figure proves that the slope

method can be applied for flat-bladed impellers and that

KS (n) is only slightly affected by flow index, even for highly

NP

10000

1000

100

10

0.01

GUA

PAA

E1

E2

GLY & HV45

0.1

1

10

Rem

Fig. 6. Power consumption curves: comparison of shear-thinning and

Newtonian fluids for impeller FB-28-3.

1218

R.K. Thakur et al. / Chemical Engineering and Processing 43 (2004) 1211–1222

KP(n)

10000

ln K P(n) = 2127 exp[3.42(n-1)]

R 2 = 0.999

1000

100

10

1

-1

-0.8

-0.6

-0.4

-0.2

0

n-1

Fig. 7. Typical application of the slope method for impeller FB-33-3.

shear-thinning fluids. This result is valid for the five geometrical configurations used in this work.

KS (n) estimations using the direct calculation (Eq. (16))

as well as the slope method have been reported in Table 5, in

which they are compared to the results of the Couette analogy. Using Eq. (15), the largest deviation is reported for PAA

and impeller FB-33-3. One should note that KS (n) values

for GUA are in agreement with other fluids, contrary to that

had been observed previously for the power curve method,

which tends to prove that either Eq. (16) or slope method

give more accurate results than the power curve method. It

is also true that the highest deviations from the straight line

of the slope method or from the direct estimation (Table 5)

appear for the FB-33-3 agitator. However, this may be explained because measurements are particularly difficult with

this impeller, as the gap is only 1 mm: vibrations at high

rotational speed can drastically affect power consumption

measurements, while they are of little influence when the

gap is larger (for 3.5 and 6.5 mm). The results remain how-

Table 5

Comparison of Couette analogy, slope and direct calculation methods for

KS estimation

KS values

Couette (Eq. (11))

Slope method

PAA∗

E1∗

E2∗

E3∗

XAN∗

GUA∗

FB-33-3

FB-28-3

FB-28-2

FB-22-3

FB-22-2

51.9

51.6

67.4

52.6

47.6

52.9

63.7

52.9

27.3

30.4

30.8

32.0

30.5

×

30.9

29.6

27.2

29.7

×

32.1

×

30.3

–

28.5

16.0

19.0

–

20.5

19.0

18.5

–

–

16.0

18.3

×

–

–

18.0

–

–

(*) From the direct calculation (Eq. (16)); (×) not in the experimental

design; (–) accurate estimation of KS not possible.

ever quite satisfactory, even for this impeller. The high KS (n)

value observed with PAA and impeller FB-33-3 cannot be

attributed to viscoelastic forces because these are known to

decrease KS (n) [12,15]. For flat-bladed impellers driven under high-speed conditions, it seems that the effect of viscoelasticity is overshadowed by shear-thinning, which is in

agreement with the conclusions of Doraiswamy et al. [12].

This result is particularly important for gas dispersion, as

bubbles introduced in non-Newtonian media tend to increase

their viscoelastic character [6].

The influence of impeller geometry on KP (n) and KS (n)

can be analyzed as a function of element number and diameter. Even for non-Newtonian fluids, KP (n) seems to be

nearly proportional to ne , which is in agreement with the

results obtained for KP with Newtonian fluids (Eq. (4)). As

shown in Fig. 6, KP (n) values exhibit a strong dependence

on n and decrease significantly with n. By contrast, the influence of the gap size on KP (n) decreases as shear-thinning

behavior increases. As already seen for Newtonian fluids,

KS (n) depends only slightly on ne . Power curve method,

slope method as well as the direct method are in good agreement and show that KS (n) is nearly independent of n between 0.1 and 1. As a conclusion, the Metzner–Otto concept

seems to be valid for flat-bladed impellers. KS (n) depends

therefore only on the gap size. Using the direct calculation,

KS (n) can be fitted using the following expression:

D

KS (n) = KS = exp 3.41

+ 0.86

(17)

DC

Note that this relation only slightly differs from Eq. (12)

which had been obtained using only Newtonian fluids.

Eq. (17), as well as KS (n) values reported in Tables 4 and 5,

show that the slope method and the direct approach generally lead to slightly higher values than the Couette method.

The results are however quite close if we consider that they

stem from different fluids and experiments. As a conclusion, it appears that KS values from the modified Couette

analogy and other techniques can be considered as equal for

flat-bladed impellers and that there is a good compatibility

between the Couette analogy developed in this work and

more conventional methods.

Finally, KP (n) can therefore be predicted by combining

Eqs. (4), (16) and (17):

ne Le

DC − D −0.42

KP (n) = 164.8

D

D

n−1

D

× exp 3.41

+ 0.86

DC

(18)

Eq. (18) allows the calculation of a unique generalized dimensionless power curve for any flat-bladed impeller. This

requires the definition of an apparent Reynolds number Rea

expressed as

Rea =

ρN 2−n D2

kKn−1

S

(19)

R.K. Thakur et al. / Chemical Engineering and Processing 43 (2004) 1211–1222

NP

10000

1000

100

GUA

PAA

E1

E2

GLY & HV45

Eq. (18)

10

0.1

1

10

100

Rea

Fig. 8. Generalized dimensionless power consumption curve for impeller

FB-28-3.

Fig. 8 illustrates the plot of NP versus Rea for impeller

FB-28-3: all power draw data are brought together into a

single dimensionless curve, regardless of flow index n. This

figure can also be compared to the set of original power

draw curves (Fig. 6). Similar plots are obtained with other

impeller geometries.

3.3. Relative mixing effectiveness

For homogenization or distributive mixing, the mixer effectiveness depends on two main factors: power consumption and mixing time. However, defining mixing effectiveness is a difficult task and it is generally easier to define

an effectiveness parameter relative to a reference or a parameter which compares the performance of two impellers

[20]. For dispersive mixing, the aim of which is to decrease

the characteristic size (d) of the dispersed phase, it is generally admitted that the mean bubble or droplet size formed

by mechanical stirring in the laminar regime is adequately

described by the dimensionless laminar Weber number We

defined as follows:

τd

k (KS N)n d

We =

=

(20)

σ

σ

where σ is the surface tension for bubbles and the interfacial tension for droplets. The key parameter for dispersive

mixing in Eq. (20) is therefore the effective shear stress applied to the dispersed phase. As previous works have shown

that flat-bladed impellers are efficient for gas dispersion in

non-Newtonian fluids [6], it may be interesting to compare

the stress level applied by flat-bladed impellers as a function

1219

of n to that applied by other more conventional agitators.

This comparison can be conducted as a function of rotational speed, but it seems preferable to consider power consumption rather than rotational speed. A good impeller for

dispersive mixing should indeed provide a high KS values

at the lowest power consumption. The following paragraph

is devoted to the definition of an indicator able to take both

kinds of parameters into account.

In order to compare the mixing characteristics of

flat-bladed impellers to more conventional agitators, two

conventional impellers denoted as reference systems were

selected. The first one is a cylinder which corresponds to

a classical Couette device. The main advantage is that this

particular configuration can be described analytically. The

second reference impeller is an helical ribbon impeller that

has been studied in many works summarized in reference

[1]. The authors report both experimental data and correlations able to predict KP as a function of the geometrical

ratios of these impellers. A power ratio RP (n) based on

power consumption can therefore be defined as the ratio of

the power constant KP (n) of a standard reference impeller

to the power constant of a standard flat-bladed element estimated for the same fluid at the same rotational speed. The

standard geometry that has been retained to compare these

impellers are ne Le = D and D/DC = 0.88. As a result,

RP (n) can be expressed as follows:

RP (n) =

KP (reference; ne Le = D; D/DC = 0.88; n)

KP (flat-bladed; Le = D; D/DC = 0.88; n)

(21)

RP decreases when additional power is required by the

flat-bladed impeller as compared to the reference agitator.

Similarly, one can define a ratio based on effective shear

stress RS (n) that represents the difference in effective shear

stress between two impellers for the same fluid at the same

rotational speed:

KS (flat-bladed; ne Le = D; D/DC = 0.88; n) n

RS (n) =

KS (reference; Le = D; D/DC = 0.88; n)

(22)

The power n in Eq. (22) stems from Eq. (20). Arbitrarily,

one suggests to define the relative effectiveness parameter

Eff(n) which takes both power consumption and stress level

into account as follows:

Eff(n) = RaS × R1−a

P

(23)

The exponent a (0 < a < 1) used to weight each factor is

chosen arbitrarily: when a is higher than 0.5, Eq. (23) tends

to emphasize the influence of the effective shear rate as a

key parameter, while a similar effect is observed for power

requirements when a is lower than 0.5. For practical applications, Eff evaluates the expense of a difference in effective

shear stress between two impellers in terms of power consumption. High values of Eff at a given n value are therefore

an indicator of an impeller adequate for dispersive mixing.

1220

R.K. Thakur et al. / Chemical Engineering and Processing 43 (2004) 1211–1222

1.5

1.25

1

0.75

0.5

0.25

0

0

0.2

0.4

0.6

0.8

1

n

Fig. 9. Evolution of RP , RS and Eff with concentric cylinders as a reference.

For dispersive mixing, a must be chosen higher than 0.5: it

is usually 1 (Eff = RS ) in biological and food applications

for which the only key parameter is the characteristic size of

the dispersed phase. As an illustration, the results presented

below use a = 0.75.

Eq. (4) gives KP = 380.5 for the standard flat-bladed impeller (ne Le = D; D/DC = 0.88). RP and RS values can

be estimated using the relations provided by the literature

for helical ribbon impellers [1] and the analytical solution

of the Couette flow for concentric cylinders. As a result, Eff

values can be evaluated. RP , RS and Eff for a = 0.75 are

reported, respectively in Fig. 9 for concentric cylinders and

in Fig. 10 for the helical ribbon as a reference. Fig. 9 shows

that RS decreases slightly when n increases, while RP rises

slightly with n when the Couette geometry is the reference.

Actually, the effective shear rate produced by flat-bladed

impellers is always around 80% of that of concentric cylinders. RS tends to 1 when n tends to 0.1, which proves that

1.5

1.25

1

0.75

0.5

RP

RS

Eff

0.25

0

0

0.2

0.4

0.6

0.8

1

n

Fig. 10. Evolution of RP , RS and Eff with helical ribbon as a reference.

flat-bladed impellers tend to behave as concentric cylinders

when pseudoplasticity increases. Consequently, Eff is nearly

independent of n in the range 0.1–1 and remains close to

1 (Fig. 9). As a conclusion, the indicator Eff shows that

flat-bladed impellers and Couette device are equivalent in

terms of dispersive mixing effectiveness for a = 0.75.

Conversely, when the helical ribbon impeller is taken as

a reference (Fig. 10), RP presents a steep increase when n

decreases below 0.4. RP becomes even higher than 1 when

n is lower than 0.18. As the effective shear rate is higher for

flat-bladed impellers, apparent viscosity remains lower and

power consumption dramatically decreases for flat-bladed

impellers as compared to helical ribbons when n is low. RS

also appears to increase when n decreases (Fig. 10), but

only slightly due to the exponent n that is used for the calculation of the effective shear stress (Eq. (22)). RS remains

however always higher than 1. Finally, Eff increases when

n decreases and is far higher than 1 when n is lower than

0.3. As expected, flat-bladed impellers have to be preferred

for dispersive mixing in highly shear-thinning fluids. Note

that this is important for chemical and food applications involving complex media. For example, most food emulsions

prepared based on milk or meat present a flow index value

between 0.25 and 0.3.

Finally, the results provided by the indicators RS and Eff

for both reference impellers are found to be in agreement

with the literature. First, helical ribbon are known to be

poorly effective for gas dispersion in highly shear-thinning

fluids, which is confirmed by the high Eff and RS values

obtained in Fig. 10. Conversely, flat-bladed impellers have

been proved to form bubbles with a characteristic size similar

to that of solid rotors in food emulsions, between 40 and

50 m [6]. This is in agreement with RS and Eff value around

1 in Fig. 9.

4. Summary and conclusions

In this work, flat-bladed impellers have been described

quantitatively in terms of power consumption and effective

shear rate as a function of impeller geometry and pseudoplasticity of the fluid in the laminar mixing region. The

influence of highly shear-thinning behavior has been highlighted. Power constant KP can be predicted as a function of

impeller length and clearance. KP (n), as well as the proportionality constant KS (n) for effective shear rate estimation

have been determined. KS values found using the modified

Couette analogy, the power curve method, the direct calculation as well as Rieger and Novak’s approach are in good

agreement and support the hypothesis that KS is nearly independent on flow index n even for highly shear-thinning

fluids and depends only on the gap dimension. As a result, the Metzner–Otto concept is valid for all the geometries studied here, regardless of impeller length and clearance. A unique dimensionless power draw curve has been

obtained for each impeller geometry. The indicators Eff and

R.K. Thakur et al. / Chemical Engineering and Processing 43 (2004) 1211–1222

RS defined for estimating the ability of impellers to apply

high shear stress at low power requirements both confirm

that flat-bladed impellers could be valuable tools for dispersive mixing in highly shear-thinning fluids, as they maintain

a high shear rate level, regardless of pseudoplasticity. This

agrees with the results of gas dispersion experiments using

flat-bladed impellers [6]. Viscous effects seem to be predominant over elasticity, which is also favorable to gas dispersion processes, as a gas phase in form of bubbles can add

a non-negligible elastic component to a non-Newtonian viscous fluid. Flat-bladed impellers can also be recommended

for use in mixer viscosimetry techniques, especially for rheologically evolving systems. Owing to the applicability of

the modified Couette analogy, the simultaneous estimation

of the effective shear rate and the apparent viscosity is now

possible, even when the rheological properties of the fluid

are unknown. This opens new perspectives for the analysis

of batch and continuous dispersion processes.

Appendix A

In a Couette system, torque is known to be independent

of the radial coordinate r. As a result, torque balance on a

Couette system can be written as

∀r,

T = 2πr 2 ne Lτ(r)

(A.1)

Injecting Eq. (1) gives

T = 2πr2 ne Le k[γ̇(r, n)]n

When r = DC /2, one obtains

n

2

2T = πDC

ne Le k γ̇(DC /2, n)

(A.2)

which finally gives Eq. (A.6), identical to Eq. (7).

−n/2

2 1/n

πkn

L

D

4πN

e

e

C

D∗ = DC 1 +

n

2T

Appendix B. Nomenclature

a

d

weighting parameter (Eq. (23))

diameter of gas bubble or droplet (m)

DC

Eff

f(r)

k

KP

KP (n)

KS

KS (n)

Le

n

ne

N

N1

NP

p

q

r

ro

RP (n)

RS (n)

R2

Re

Rea

Rem

T

We

(A.3)

diameter of impeller or cylinder (m)

equivalent impeller diameter in a Couette

geometry (m)

diameter of the column or shell (m)

effectiveness factor (Eq. (23))

objective function (Eq. (10))

consistency factor (Eq. (1)) (Pa sn )

power constant (Eq. (3))

generalized power constant (Eq. (15))

shear rate proportionality constant (Eq. (5))

generalized shear rate proportionality

constant (Eq. (16))

length of a mixing element (m)

flow index (Eq. (1))

number of mixing elements

rotational speed (s−1 )

primary normal stress difference (Eq. (2)) (Pa)

power number or Newton number

viscoelasticity factor (Eq. (2)) (Pa sq )

viscoelasticity index (Eq. (2))

radial coordinate (m)

fitted parameter of Couette analogy (m)

power constant ratio (Eq. (21))

effective shear rate ratio (Eq. (22))

correlation coefficient

rotational Reynolds number

apparent Reynolds number (Eq. (19))

modified Reynolds number (Eq. (14))

torque measured on the shaft of the

impeller (N m)

laminar Weber number (Eq. (20))

(A.4)

Greek letters

γ̇

shear rate (s−1 )

γ̇a

effective shear rate (Eq. (5)) (s−1 )

µ

fluid viscosity (Pa s)

ρ

fluid density (kg m−3 )

σ

surface/interfacial tension (N m−1 )

τ

shear stress (Pa)

(A.5)

References

Combining Eq. (A.3) and Eq. (6) provides

∗ 2/n −1 n

∗ 2/n D

4πN

D

2

1−

ne Le k

2T = πDC

n

DC

DC

Eq. (A.5) can also be expressed as

2 n L k 1/n

4πN πDC

DC 2/n

e e

−1=

D∗

n

2T

D

D∗

(A.6)

1221

[1] E. Brito-De La Fuente, L. Choplin, P.A. Tanguy, Mixing with helical ribbon impellers: effect of highly shear thinning behaviour and

impeller geometry, Trans. Inst. Chem. Eng. 75A (1997) 45–52.

[2] T. Espinosa-Solares, E. Brito-De La Fuente, A. Tecante, L.

Medina-Torres, P.A. Tanguy, Mixing time in rheologically evolving

fluids by hybrid dual mixing systems, Trans. Inst. Chem. Eng. 80A

(2002) 822.

[3] W. Hanselmann, E. Windhab, Foam generation in a continuous

rotor–stator mixer, in: G.M. Campbell, C. Webb, S.S. Pandiella, K.

Niranjan (Eds.), Bubbles in Food, Eagan Press, MN, USA, 1999.

[4] D.R.G. Cox, A.J. Gerrard, L. Wix, Power consumption and backmixing in horizontal scraped surface heat exchangers, Trans. Inst.

Chem. Eng. 71C (1993) 187–193.

1222

R.K. Thakur et al. / Chemical Engineering and Processing 43 (2004) 1211–1222

[5] A.B. Russell, S.S.H. Burmester, P.J. Winch, Characterisation of

shear-thinning flow within a scraped surface heat exchanger, Trans.

Inst. Chem. Eng. 76C (1997) 191–197.

[6] R.K. Thakur, C. Vial, G. Djelveh, Influence of operating conditions

and impeller design on the continuous manufacturing of food foams,

J. Food Eng. 60 (2003) 9–20.

[7] R.L. Stewart, J. Bridgwater, D.J. Parker, Granular flow over a

flat-bladed stirrer, Chem. Eng. Sci. 56 (2001) 4257–4271.

[8] A.B. Metzner, R.E. Otto, Agitation of non-Newtonian fluids, Am.

Inst. Chem. Eng. J. 3 (1957) 3–9.

[9] F. Rieger, V. Novak, Power consumption of agitators in highly viscous

non-Newtonian liquids, Trans. Inst. Chem. Eng. 51 (1973) 105–111.

[10] N. Harnby, M.F. Edwards, Nienow, Mixing in the Process Industries,

second ed., Butterworths-Heinemann, Oxford, UK, 1992.

[11] S. Nagata, Mixing—Principles and Applications, Kodansha, Tokyo,

Japan, 1975.

[12] D. Doraiswamy, R.K. Grenville, A.W. Etchells, Two-score years of

the Metzner–Otto correlation, Ind. Eng. Chem. Res. 33 (1994) 2253–

2258.

[13] M.A. Rao, H.J. Cooley, Determination of effective shear rates in

rotational viscosimeters with complex geometries, J. Text. Stud. 15

(1984) 327–335.

[14] M.E. Castell-Perez, J.F. Steffe, Evaluating shear rates for power law

fluids in mixer viscosimetry, J. Text. Stud. 21 (1990) 439–453.

[15] P.J. Carreau, R.P. Chabra, J. Cheng, Effect of rheological properties

on power consumption with helical ribbon agitators, Am. Inst. Chem.

Eng. J. 39 (1993) 1421–1430.

[16] E. Chavez-Montes, L. Choplin, E. Schaer, Etude du foisonnement

et de la congélation dans un rhéo-réacteur: application aux crèmes

glacées, in: Proceedings of the 8th Congrès Francophone de Génie

des Procédés, Nancy, France, 17–19 October 2001.

[17] S.M. Shekhar, S. Jayanti, Mixing of power-law fluids using anchors:

Metzner–Otto concept revisited, Am. Inst. Chem. Eng. J. 49 (2003)

30–40.

[18] J.J. Ulbrecht, P.J. Carreau, Mixing of viscous non-Newtonian liquids, in: J.J. Ulbrecht, G.R. Patterson (Eds.), Mixing of Liquids by

Mechanical Agitation, vol. 1, Gordon and Beach, New York, USA,

1985, pp. 93–137.

[19] K.L. Mackey, R.G. Morgan, J.F. Steffe, Effects of shear-thinning

behavior on mixer viscosimetry techniques, J. Text. Stud. 18 (1987)

231–340.

[20] N.I. Patterson, P.J. Carreau, C.Y. Yap, Mixing with helical-ribbon

agitators. II. Newtonian fluids, Am. Inst. Chem. Eng. J. 25 (1979)

508–515.