Thermal Spray Liners

advertisement

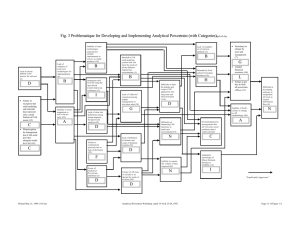

Powertrain Systems February 2014 Property of Comau - Duplication prohibited THERMAL SPRAY LINERS POWERTRAIN February 2014 Powertrain Systems Property of Comau - Duplication prohibited 2 2 1998 1 Car …now in 2014 16 Cars and Growing Efficiency Performance February 2014 Powertrain Systems Property of Comau - Duplication prohibited 3 3 Thermal Spray Liners 1. Advantages of Monolithic Block with a coating • • • • • Cost Weight Reduction Improved Durability Flexible Manufacturing Packaging 2. Improvement of Thermodynamics •NVH, Knock & Friction Reduction •Fuel Economy/Emissions •Packaging •No Gaps, Low Heat (Q) Capacity 3. Improvement of Tribology •Friction Reduction •Fuel Economy •Improved Durability •Start Stop Enabler •Emissions * As compared to cast-in Cast Iron and HiSilicon Liners February 2014 Powertrain Systems Property of Comau - Duplication prohibited 4 Challenges – Where’s the Energy Going Source: Mazda, CAR 12/12 February 2014 Powertrain Systems Property of Comau - Duplication prohibited 5 5 3. PTWA Friction Reduction PTWA offers potential for reduced friction by allowing smoother honing while maintaining oil retention due to thermal spray porosity SIGMA 1.6l Liner vs.. PTWA Ford/FSI SAE paper 2008 February 2014 Powertrain Systems Property of Comau - Duplication prohibited 6 3. Friction Reduction Measured Chrysler D.O.E. Development Engine, Chrysler/DOE Review 2011 SIGMA 1.6l Liner vs.. PTWA Ford/FSI SAE paper 2008 February 2014 Powertrain Systems Property of Comau - Duplication prohibited 7 THERMAL SPRAY TECHNOLOGY February 2014 Powertrain Systems Property of Comau - Duplication prohibited 8 8 PTWA Key Features Plasma Transferred Wire Arc Pros Consistent Porosity Process Stability and Repeatability High Wire Capacity Ability to coat with large range of wire products Dust K-factor of zero Customer Concerns 1st February 2014 Automotive Production: 2007 Nissan w/FSI 2010 Ford Using non-mixed Hydrogen gas (addressed) Powertrain Systems Property of Comau - Duplication prohibited 9 SURFACE ROUGHENING TECHNOLOGIES February 2014 Powertrain Systems Property of Comau - Duplication prohibited 1010 Surface Prep: Background Comparison of Grit Blasted To Water Jet Prepared Water Jet: Grit Blast: February 2014 Grit must follow the angle of reflection. Follows fluid stream dynamics. Mechanical Impact and Wear of the Substrate. Erosion of the substrate. Requires aggressive cleaning and drying. Drying only. Powertrain Systems Property of Comau - Duplication prohibited 11 Surface Prep: Background Mechanical Surface Fine Bore Finishing Nissan (Production) • Cuts and breaks threaded form Tool Travel Deformed Square Groove Threaded form • Cut then plastically deform fin of substrate Targetted form • Concentric grooves with mechanical forging Braunshweig (Limited Production) • Cuts dove tail in threaded form Key Characteristics: • Substrate Quality ( can handle porosity <1.25mm) • Surface complexity and Roughness • Process Stability and Measurability • Surface must be clean and dry, not required by dry or MQL machining February 2014 Powertrain Systems Property of Comau - Duplication prohibited 12 COATING CHARACTERISTICS February 2014 Powertrain Systems Property of Comau - Duplication prohibited 1313 A Basic PTWA Coating February 2014 Low Carbon steel wire Composition: 0.1C, 0.6Mn,0.045P, 0.04S Fe Balance Low Cost Wire Compatible with conventional Piston Ring Packs Porosity is approx. 2% Wuestite and Iron matrix • The combination of Wuestite(FeO) and porosity reduce the friction and wear of the honed surface Powertrain Systems Property of Comau - Duplication prohibited 14 THERMAL SPRAY LINER IMPLEMENTATION February 2014 Powertrain Systems Property of Comau - Duplication prohibited 1515 Keys to Successful Implementation • Processing Configuration Linerless Casting Heat Treat • Casting Process • Type • Casting Quality • Block Design February 2014 Super Cubing Machining Crank Bore Leak Test / Impregnation Boring – Mech Prep Final Machining Honing Washing • Coating Morphology • Coating Thickness • Overspray Processing Configuration Depending on the integration type: • Greenfield • Brownfield Need to balance your goals of: • Manufacturing simplicity • Engine Performance • Cost • Investment Recommended implementation: • Fine Boring with Surface Preparation • Coating • Finish Boring with Rough Hone Thermal Spray • Coating Morphology • Coating Thickness • Overspray • Deposition • Surface Roughness • Adhesion • Final Coating Roughness • Cleanliness • Adhesion • Coating Quality Powertrain Systems Property of Comau - Duplication prohibited 1616 February 2014 Powertrain Systems Property of Comau - Duplication prohibited 17 SMARTspray-PTWA Production Cell Fully Integrated Cell on a Common Chassis Robot controller Load/unload robot or robot gantry load Gas panel 2 door elec. enclosure *patent pending air flow Torch power supply “L” shaped automatic doors February 2014 Powertrain Systems Property of Comau - Duplication prohibited 18 SMARTspray Liner System Value Propositions : ● Minimum foot print installation : 15 m² ● H2On: On board hydrogen generation ● High deposition efficiency ● Dual Spindle and output capability ● Low operating cost ● Patent Pending bore coating control process ● On the floor bulk feed stock ● Low as-sprayed coating roughness ● Patent pending targetted roughening February 2014 Powertrain Systems Property of Comau - Duplication prohibited 19 Support Capabilities Prototyping Engineering Design support for Adaptation of Liner Systems • 50+ years of broad Thermal Liner Coating Experience Prototype • Currently capable of handling up to 900lbs and bores down to 67mm diameter, machining and hone supply base • 4th Quarter 2013: In-house surface roughening, and bores down to 37mm, Autolab with functioning production cell Production Development Comau can be your single source for a full block production system (Machining, Material Handling, Inspection, Surface Preparation, Coating and Honing, Cleaning, Assembly and Test) to just a single equipment source(CNCs, Coating cells, Assembly centers, and Test stands) Customer Support February 2014 Thermal Spray Core group is located in Royal Oak, Mi Support Staff in Shanghai, China and Turin, Italy. • 4th Quarter Additional Support group in Mexico City, Mexico Powertrain Systems Property of Comau - Duplication prohibited 20 COMAU S.p.A. Via Rivalta, 30 10095 GRUGLIASCO (TO) ITALY www.comau.com February 2014 Powertrain Systems Property of of Comau Comau -- Duplication Duplication prohibited prohibited Property 21