Multi-Story Fittings

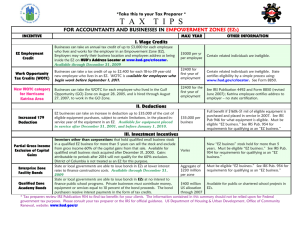

advertisement

Cast Iron Multi-Story BR-CI-MS APPLICATION GUIDE AND DIMENSIONAL CATALOG Cast Iron Fitting Products for Multi-Story Applications Revit® Drawings Available at www.charlottepipe.com (Updated October 20, 2015) © 2012-2015 Charlotte Pipe and Foundry Company Multi-Story Fittings TABLE OF CONTENTS............................................................................................................. PAGE Anatomy of a Starter Fitting............................................................................................................. 3 Multi-Story Hubless Typical Installations.........................................................................................4-8 Multi-Story Hubless Fittings......................................................................................................... 9-11 Multi-Story Hubless Extended Fittings........................................................................................ 12-13 Multi-Story Hubless Fixture Fittings........................................................................................... 14-25 Multi-Story Hubless Starter Fittings...........................................................................................25-37 Hubless Application Index................................................................................................................ 38 EZS 700 and EZS 800 Minimum Space Requirements..................................................................... 39 Multi-Story Service Typical Installation............................................................................................40 Multi-Story Tapped Service Fittings............................................................................................ 41-42 Multi-Story Service Fixture Fittings............................................................................................43-48 Multi-Story Service Starter Fittings............................................................................................49-54 Service Weight Application Index..................................................................................................... 55 Minimum Space Requirements for Multi-Story Service Starter Fittings............................................. 56 Limited Warranty............................................................................................................................ 57 Download our Tech Tools App for dimensional info, tech calculators and more on your mobile device. All detail drawings included in this manual can be downloaded as DWG or PDF documents at www.charlottepipe.com. 2 Multi-Story Fittings Thank you for your interest in Charlotte Pipe and Foundry Starter Fittings. Charlotte Pipe and Foundry offers both Hubless and Service fittings for multi-story applications. Our fittings have been designed in cooperation with generations of commercial contractors to make commercial DWV installations more efficient. Used in combination with thoughtful plumbing design, Starter Fittings will reduce the total number of fittings in an installation. They reduce the number of joints, minimize the complexity of distributing fittings on a job site, fit better within confined plumbing walls, and improve the overall quality of a job. This maximizes profitability for the installing contractor. Another user-friendly feature of our Starter Fittings is the ability to custom order vent and inlet positions to fit building needs. Charlotte Pipe products are proudly manufactured in the USA. Please contact Charlotte Pipe with any questions on the application of these fittings, comments or recommendations. The Anatomy of a Starter Fitting 1 Fixture Fitting + Hubless Coupling + 2 Sanitary Tee + Hubless Coupling + 3Wye + Hubless Coupling + 4Pipe Equals Revit® Drawings Available at www.charlottepipe.com Charlotte Pipe and “You can't beat the system” are registered trademarks of Charlotte Pipe and Foundry Company. 3 Multi-Story Fittings Multi-Story Hubless Fittings TYPICAL HIGH-RISE BUILDING INSTALLATION EZS 800 STACKED PERSPECTIVE 2” HUBLESS CAST IRON PIPE VENT LINE 4” HUBLESS CAST IRON PIPE DRAIN LINE 2” HUBLESS CAST IRON FINISHED FLOOR P-TRAP (TYPICAL) CONTRACTOR SHALL USE PART NO. EZS 800R 2” HUBLESS CAST IRON PIPE VENT LINE CONTRACTOR SHALL USE PART NO. EZS 7L 4” HUBLESS CAST IRON PIPE DRAIN LINE 2” HUBLESS CAST IRON FINISHED FLOOR P-TRAP (TYPICAL) CONTRACTOR SHALL USE PART NO. EZS 800R 2” HUBLESS CAST IRON PIPE VENT LINE CONTRACTOR SHALL USE PART NO. EZS 7L 4” HUBLESS CAST IRON PIPE DRAIN LINE 2” HUBLESS CAST IRON FINISHED FLOOR P-TRAP (TYPICAL) CONTRACTOR SHALL USE PART NO. EZS 800R All products manufactured by Charlotte Pipe and Foundry Company are proudly made in the U.S.A. 4 Multi-Story Fittings Typical Installations EZS 700D DOUBLE FLOOR MOUNT BACK OUTLET APPLICATION EZS 700R WALL MOUNT BACK OUTLET APPLICATION 5 Multi-Story Fittings Typical Installations EZS 800D DOUBLE FLOOR MOUNT BACK OUTLET APPLICATION 6 EZS 800R WALL MOUNT BACK OUTLET APPLICATION Multi-Story Fittings Typical Installations EZS 800D DOUBLE WALL MOUNT BACK OUTLET APPLICATION 7 Multi-Story Fittings Typical Installations EZS 800L FLOOR MOUNT BACK OUTLET APPLICATION 8 EZS 800R FLOOR MOUNT BACK OUTLET APPLICATION Multi-Story Fittings Multi-Story Hubless Fittings EZS 2” Vent Cross-Over For use with EZS 50 through 800 Series Fittings PART NO. EZS 7L 2” Vent Cross-Over with Left Hand Inlet PART NO. EZS 7 2” Vent Cross-Over, Plain (No Outlets) *U.P.C. No. 611942 04429 Size 2 x 183⁄8 A 47⁄8 C 93⁄16 F Weight 183⁄8 8.1 PART NO. EZS 7D 2” Vent Cross-Over, Double *U.P.C. No. 611942Size 04431 2 x 18 ⁄8 3 *U.P.C. No. 611942 Size 04430 2 x 183⁄8 A 47⁄8 B C 4 ⁄8 6 ⁄2 9 ⁄16 7 1 3 F Weight 183⁄8 8.2 PART NO. EZS 7R 2” Vent Cross-Over with Right Hand Inlet (2 Inlets) *U.P.C. No. 611942 Size ABC FWeight 61⁄2 93⁄16 183⁄8 A B C 47⁄8 61⁄2 93⁄16 FWeight 183⁄8 8.4 8.0 HOW TO DETERMINE RIGHT or LEFT HAND CROSS-OVER With the vented end toward you, hold the fitting so that you are looking into its length with the curved side up. If the vent is on your left side, it is a Left Hand fitting. If the vent is on your right side, it is a Right Hand fitting. (Right Hand Cross-Over Illustrated) 04432 2 x 183⁄8 Note: VENT CROSS-OVER for use with EZS-50 through 800 Series fittings. Specify Right, Left, Plain or Double. Note: Our crossovers are designed for use with EZS starter fittings, that is for the vent and stack centerline to be 61 ⁄2” 9 Multi-Story Fittings EZS 7R 2” Vent Cross-Over VENT STACK WALL HUNG LAVATORY WALL HUNG LAVATORY FINISHED FACE OF WALL WASTE STACK CONTRACTOR SHALL USE PART NO. EZS 7R 2” VENT CROSS-OVER WITH RIGHT HAND INLET FLOOR MOUNTED BACK OUTLET TOILET FLOOR MOUNTED BACK OUTLET TOILET CONTRACTOR SHALL USE PART NO. EZS 38 CONTRACTOR SHALL USE PART NO. EZS 800D TUB TUB 2” VENT CROSS-OVER FITTING RIGHT HAND CONTRACTOR SHALL USE PART NO. EZS 7R 2” VENT CROSS-OVER WITH RIGHT HAND INLET VENT STACK RY TO VA LA RY TO VA LA WASTE STACK T ILE TO ILE TO T B TU B TU 2” VENT CROSS-OVER FITTING RIGHT HAND RISER DIAGRAM 10 Multi-Story Fittings PART NO. EZS 9 P-Trap with 11⁄2” Tapped Side Inlet Size H 2 F PART NO. EZS 38 Vented Tub Wye Weight 53⁄1671⁄26.2 Size G PART NO. EZS 10 P-Trap with 2” Side Inlet Size C D H F Weight 2 91⁄251⁄4 159.4 2 2451⁄4291⁄213.7 PART NO. EZS 38L Vented Tub Wye Left Hand J Weight 21 ⁄167 ⁄23 ⁄166.4 3 1 1 Size G H F Weight 29 ⁄23 ⁄4 1510.0 1 PART NO. EZS 13 45° Vented Tub Wye Size E F G 3 PART NO. EZS 38R Vented Tub Wye Right Hand Weight 2 1251 ⁄4153 ⁄410.1 Size G H F Weight 29 ⁄23 ⁄4159.0 1 3 11 Multi-Story Fittings Multi-Story Hubless Extended Fittings PART NO. EZS 14 Extended Short Sweep Size 2 x 18 2 x 24 2 x 34 E F PART NO. EZS 16 2” x 24” Two-Way Sanitary Tee Weight 61⁄2 188.0 61⁄2 2411.0 61⁄2 3413.9 PART NO. EZS 15 Extended Combination Size 12 2 x 24 2 x 36 E F G Weight 63⁄16253⁄82412.0 63⁄1636 343⁄415.4 Size E H 1 2 x 18 2 x 24 F Weight 4 ⁄24 ⁄2187.8 41⁄241⁄2 2410.4 1 PART NO. EZS 17 2” x 227⁄8” Extended Tapped Sanitary Tee Size H F Weight 2 x 1 ⁄2 x 22 ⁄83 ⁄422 ⁄89.6 2 x 2 x 227⁄833⁄4227⁄89.2 1 7 1 7 Multi-Story Fittings PART NO. EZS 18 2” x 22 ⁄ ” Extended Tapped Sanitary Cross PART NO. EZS 28 Sanitary Tapped Cross 7 8 Size H F Weight 2 x 11⁄2 x 227⁄831⁄4227⁄810.0 2 x 2 x 227⁄833⁄4227⁄811.9 Size PART NO. EZS 27 Sanitary Tapped Tee 2 x 11⁄2 x 31 2 x 2 x 31 F Weight E 13 16 F 3 G 1 H Weight 1 111⁄43112.6 111⁄43113.6 PART NO. NH 27 Tapped Double Wye Size Weight 2 x 1 ⁄22 ⁄ 9 ⁄44 ⁄23 ⁄44.8 1 H F 111⁄4 3115.0 111⁄4 3115.0 PART NO. EZS 35B Double Vertical Sanitary Tapped Tee Size Size H 2 x 11⁄2 x 31 2 x 2 x 31 D F Testing with or use of compressed air or gas in Cast Iron pipe or fittings can result in explosive failures and cause severe injury or death. Weight 2 x 11⁄251⁄1665 ⁄85.6 • NEVER test with or transport/store compressed air or gas in Cast Iron pipe or fittings. • NEVER test Cast Iron pipe or fittings with compressed air or gas. • ONLY use Cast Iron pipe and fittings for drain, waste and vent or sanitary sewer applications. 13 Multi-Story Fittings Multi-Story Hubless Fixture Fittings PART NO. NH 502 4” No Hub Prison Fitting with 2” Top Vent (Designed for use above the floor; Baffle helps prevent passage of contraband between cells.) Part No. NH 502 NH 502 NH 502 NH 502 14 Size 4 Less Tap 4 With Tap 4x3 Less Tap 4x3 With Tap UPC# 611942- A 00639 00640 11119 11120 8 8 8 8 C F 5 ⁄4 12 51⁄4 12 51⁄4 12 51⁄4 12 1 G Weight 820.3 820.8 823.4 823.4 Multi-Story Fittings PART NO. NH 502 Detail Drawing 4” No Hub Prison Fitting with 2” Top Vent and 2” 45° Tap Service for Two Cells at 45° Angle 15 Multi-Story Fittings PART NO. EZS 6* Figure Six PART NO. EZS 8* Figure Eight (Double, Left Hand or Right Hand; Designed for use below the floor; Double fitting has a baffle) (Double, Left Hand or Right Hand; Designed for use below the floor; Double fitting has a baffle) (Photos Show Double) (Photos Show Left Hand) Part No. Size C D E 1 9 1 F H Weight EZS 6D** 3x2 EZS 6D** 4x2 4 ⁄87 ⁄165 ⁄16113 ⁄1613.0 N 41⁄29 61⁄213 423.1 N EZS 6L EZS 6L 3x2 4x2 41⁄879⁄1651⁄161137⁄1611.4 N 1 1 4 ⁄29 6 ⁄213 418.0 N EZS 6R EZS 6R 3x2 4x2 4 ⁄87 ⁄165 ⁄16113 ⁄1611.4 N 41⁄29 61⁄213 418.0 N 1 9 1 7 7 *When ordering please specify Double, Left or Right. ** Double fitting has a baffle. N = non-stock item – contact customer service for availability. 16 Part No. Size C D E 1 9 1 F H Weight EZS 8D**3x2 4 ⁄87 ⁄165 ⁄16113 ⁄1613.0 N EZS 8L 3x2 EZS 8L 4x2 41⁄879⁄1651⁄161137⁄1612.5 N 41⁄29 61⁄213 419.8 N EZS 8R 3x2 EZS 8R 4x2 41⁄879⁄1651⁄161137⁄1612.5 N 1 1 4 ⁄29 6 ⁄213 419.8 N 7 *When ordering please specify Double, Left or Right. ** Double fitting has a baffle. Multi-Story Fittings PART NO. EZS 6D Detail Drawing 4x2 Vented Closet Tee - Right Hand with 2” Top Vent 5-1/2” MIN. FINISHED FACE OF WALL FINISHED FACE OF WALL HIDDEN LINE INDICATES EXTENSION OF 4” WASTE PIPING (ALSO AVAILABLE FOR 3” STACK SIZE) INTEGRAL 2” VENT STACK FITTING OPPOSITE SIDE FLOOR MOUNTED BOTTOM OUTLET TOILET FIXTURE FLOOR MOUNTED BOTTOM OUTLET TOILET FIXTURE FINISHED FLOOR CLOSET FLANGE FINISHED FLOOR 10-1/2” CONTRACTOR SHALL USE CLOSET FLANGE PART NO. EZS 6D NO-HUB STARTER FITTING DOUBLE FITTING RIGHT HAND UNDER-SLAB - LEFT SIDE ELEVATION VERTICLE CONFIGURATION 17 Multi-Story Fittings PART NO. EZS 8D Detail Drawing 3x2 Double Figure 8 Fitting with 2” Vent 5-1/2” MIN. FINISHED FACE OF WALL HIDDEN LINE INDICATES EXTENSION OF 2” VENT PIPING FINISHED FACE OF WALL FLOOR MOUNTED BOTTOM OUTLET TOILET FIXTURE FLOOR MOUNTED BOTTOM OUTLET TOILET FIXTURE FINISHED FLOOR FINISHED FLOOR CLOSET FLANGE CLOSET FLANGE INTEGRAL 2” VENT STACK FITTING 10-1/2” CONTRACTOR SHALL USE PART NO. EZS 8D NO-HUB STARTER FITTING 9” DOUBLE FITTING UNDER-SLAB - LEFT SIDE ELEVATION HORIZONTAL CONFIGURATION 18 Multi-Story Fittings PART NO. EZS 8L Detail Drawing Vented Closet Tee - Left Hand with 2” Side Inlet 5-1/2” MIN. FINISHED FACE OF WALL HIDDEN LINE INDICATES EXTENSION OF 4” WASTE PIPING FINISHED FACE OF WALL FLOOR MOUNTED BOTTOM OUTLET TOILET FIXTURE FINISHED FLOOR FINISHED FLOOR CONTRACTOR SHALL USE 13” PART NO. EZS 8L NO-HUB STARTER FITTING CLOSET FLANGE INTEGRAL 2” INLET LEFT SIDE SINGLE FITTING LEFT HAND UNDER-SLAB - LEFT SIDE ELEVATION 19 Multi-Story Fittings PART NO. EZS 50 10” Closet Fittings with 2” Inlet PART NO. EZS 51 10” Closet Fittings with 2” Inlet and 2” Side Inlet (Double, Left Hand or Right Hand; Designed for use below the floor; Fitting does not have a baffle) (Double, Left Hand or Right Hand; Designed for use below the floor; Fitting does not have a baffle) (Photos Show Left Hand) (Photos Show Left Hand) UPC# Part No. Size 611942- EZS 50D EZS 50L EZS 50R 20 4 4 4 A B C D F Weight 04484 10 ⁄46 ⁄23 ⁄4 44 ⁄215.0 04476 103⁄461⁄233⁄4 441⁄212.3 04477 103⁄461⁄233⁄4 441⁄212.2 3 1 3 1 UPC# Part No. Size 611942- EZS A B C D E F Weight 51D 4 04424 10 ⁄46 ⁄2349 ⁄24 ⁄215.0 EZS 51L 4 04425 103⁄461⁄23491⁄241⁄212.8 EZS 51R 4 04473 103⁄461⁄23491⁄241⁄212.6 3 1 1 1 Multi-Story Fittings PART NO. NH 457 Vented Closet Tee with 2” Top Vent PART NO. NH 463 Vented Closet Cross with 2” Top Vent (Left Hand or Right Hand; Designed for use below the floor; Fitting does not require a baffle) (Designed for use below the floor; Fitting has a baffle) (Photos Show Left Hand) (Gray Area Indicates Baffle) Size B C D E F G Wt. 4x4x2x4(L) 41⁄451⁄433⁄44101⁄233⁄412.1 4x4x2x4(R) 41⁄451⁄433⁄44101⁄233⁄411.6 Size 4x4x2x4x4 B C D EF G Wt 41⁄451⁄433⁄44101⁄233⁄415.0 Double fittings are equipped with Baffles to prevent blowback on back-to-back installations of back-outlet toilets. 21 Multi-Story Fittings PART NO. NH 463 Detail Drawing - 4x4x2x4x4 Vented Closet Cross with 2” Top Vent 5-1/2” MIN. FINISHED FACE OF WALL HIDDEN LINE INDICATES EXTENSION OF 4” WASTE PIPING FINISHED FACE OF WALL INTEGRAL 2” VENT STACK FITTING FLOOR MOUNTED BOTTOM OUTLET TOILET FIXTURE FLOOR MOUNTED BOTTOM OUTLET TOILET FIXTURE FINISHED FLOOR 10-1/2” FINISHED FLOOR CONTRACTOR SHALL USE PART NO. NH 463 NO-HUB STARTER FITTING CLOSET FLANGE CLOSET FLANGE CLOSET BEND PER REQUIREMENTS CLOSET BEND PER REQUIREMENTS DOUBLE FITTING UNDER-SLAB - LEFT SIDE ELEVATION PART NO. NH 463 Baffle Detail Drawing - 4x4x2x4x4 Vented Closet Cross with 2” Top Vent INTEGRAL 2” VENT STACK FITTING INTEGRAL BAFFLE FLOW SOLID BAFFLE INTEGRALLY CAST IN CENTER OF FITTING FLOW FLOW BAFFLE ON DOUBLE FITTING FOR BACK TO BACK WATER CLOSET INSTALLATIONS. LEFT SIDE SECTION 22 10-1/2” CONTRACTOR SHALL USE PART NO. NH 463 NO-HUB STARTER FITTING FRONT OR BACK SIDE ELEVATION Multi-Story Fittings PART NO. NH 458 Vented Closet Tee with 2” Top Vent and 2” Side Inlet (Left Hand or Right Hand; Designed for use below the floor; Fitting does not require a baffle) (Photos Show Left Hand) Size A B C D EF G Wt. 4x4x2x2x4(L) 81⁄841⁄4 51⁄471⁄2 4 101⁄2 33⁄4 12.3 4x4x2x2x4(R) 81⁄841⁄4 51⁄471⁄2 4 101⁄2 33⁄4 12.2 ORDERING EZS CLOSET FITTINGS SERIES 50, 100, 400, 700,800 These No-Hub closet fittings can be ordered with Left hand, Right hand or Double closet inlets, and with 2” sanitary inlets at various heights on either side of the fitting. They can be ordered with an additional inlet (see illustrations) by adding a “1” after the first digit of the Series Number, i.e. 51, 110, 210, etc. To order, show the above information as follows: EZS Enter Series Number here 00 or 10 M Enter L (Left), R (Right) or D (Double) here B Enter height of sanitary Inlet “M” or 0 if not required Enter height of sanitary Inlet “B” or 0 if not required Example: If you were ordering a Left hand Series 100 fitting with one sanitary inlet at 13” on the “B” side of the fitting, you would write EZS 100 L M 0 B 13 or with the extra inlet, EZS 110 L M 0 B 13 M & B dimensions must be measured from the bottom of the fitting. 23 Multi-Story Fittings PART NO. NH 458 Detail Drawing 4x4x2x2x4 Vented Closet Tee/Left Hand with 2” Top Vent and 2” Side Inlet 5-1/2” MIN. FINISHED FACE OF WALL HIDDEN LINE INDICATES EXTENSION OF 4” WASTE PIPING FINISHED FACE OF WALL INTEGRAL 2” VENT STACK FITTING FLOOR MOUNTED BOTTOM OUTLET TOILET FIXTURE FINISHED FLOOR 10-1/2” CONTRACTOR SHALL USE PART NO. NH 458 NO-HUB STARTER FITTING FINISHED FLOOR CLOSET FLANGE CLOSET BEND PER REQUIREMENTS INTEGRAL 2” INLET LEFT SIDE SINGLE FITTING LEFT HAND UNDER-SLAB - LEFT SIDE ELEVATION 24 Multi-Story Fittings Multi-Story Hubless Starter Fittings PART NO. NH 464 Vented Closet Cross with 2” Top Vent and 2” Side Inlet PART NO. EZS 100* 16” Closet Fittings with 2” Inlets (Designed for use below the floor; Fitting has a baffle) (Double, Left Hand or Right Hand; Designed for use below the floor) (Photos Show Left Hand) (Gray Area Indicates Baffle) Size A B C DEF G Wt. 4x4x2x2x4x4 8 ⁄84 ⁄4 5 ⁄47 ⁄2 4 10 ⁄2 33⁄4 15.6 1 1 1 1 1 M & B dimensions must be measured from the bottom of the fitting. Part No. Size A B C D E 1 1 1 M Weight EZS 100D4x16 16 ⁄454 ⁄26 ⁄25 ⁄2 522.0 N 3 HOW TO DETERMINE RIGHT or LEFT HAND CLOSET FITTING To determine if whether a closet fitting is a right hand or left hand configuration, stand the fitting up with the closet inlet facing you. If the opening is on your left, it is a Left Hand fitting. If the opening is on your right, it is a Right Hand fitting. Right Hand and Left Hand configurations do not apply for Double fittings. (Right Hand Closet Fitting Illustrated) EZS 100L4x16163⁄4541⁄261⁄251⁄2 520.0 N EZS 100R4x16 163⁄4541⁄261⁄251⁄2 521.1 N *When ordering please specify Double, Left or Right. N = non-stock item – contact customer service for availability. 25 Multi-Story Fittings PART NO. EZS 400* 30” Closet Fittings with 2” Inlet (Double, Left Hand or Right Hand; Designed for use in the floor) (Photos Show Left Hand) Part No.Size AB CD EM Weight 4x30 4x30 4x30 4x30 4x30 4x30 4x30 4x30 4x30 4x30 4x30 30 30 30 30 30 30 30 30 30 30 30 0 41 ⁄261 ⁄251 ⁄2034.0N 6 ⁄241⁄261⁄251⁄2034.2N 12 41⁄261⁄251⁄2037.8N 261⁄241⁄261⁄251⁄2034.3N 0 41⁄261⁄251⁄2434.0N 261⁄241⁄261⁄251⁄2434.0N 0 41⁄261⁄251⁄261⁄233.1 N 61⁄241⁄261⁄251⁄261⁄234.0 N 261⁄241⁄261⁄251⁄261⁄236.8 N 0 41⁄261⁄251⁄21231.0N 261⁄241⁄261⁄251⁄21230.0N EZS 400R 4x30 EZS 400R 4x30 EZS 400R 4x30 EZS 400R 4x30 EZS 400R 4x30 EZS 400R 4x30 EZS 400R 4x30 EZS 400R 4x30 EZS 400R 4x30 EZS 400R 4x30 EZS 400R 4x30 30 30 30 30 30 30 30 30 30 30 30 0 41⁄261⁄251⁄2032.9N 6 ⁄241⁄261⁄251⁄2034.5N 12 41⁄261⁄251⁄2037.1N 261⁄241⁄261⁄251⁄2033.8N 0 41⁄261⁄251⁄2434.0N 261⁄241⁄261⁄251⁄2428.9N 0 41⁄261⁄251⁄261⁄233.9 N 61⁄241⁄261⁄251⁄261⁄235.4 N 261⁄241⁄261⁄251⁄261⁄235.4 N 0 41⁄261⁄251⁄21231.0N 261⁄241⁄261⁄251⁄21228.5N EZS 400D 4x30 EZS 400D 4x30 EZS 400D 4x30 EZS 400D 4x30 EZS 400D 4x30 EZS 400D 4x30 EZS 400D 4x30 EZS 400D 4x30 30 0 41⁄261⁄251⁄2029.3N 30 61⁄241⁄261⁄251⁄2036.4N 30 12 41⁄261⁄251⁄2039.6N 30 0 41⁄261⁄251⁄2438.0N 30 0 41⁄261⁄251⁄261⁄235.6 N 30 261⁄241⁄261⁄251⁄261⁄238.9 N 30 0 41⁄261⁄251⁄21235.7N 30 261⁄241⁄261⁄251⁄21238.0N EZS 400L EZS 400L EZS 400L EZS 400L EZS 400L EZS 400L EZS 400L EZS 400L EZS 400L EZS 400L EZS 400L 1 1 *When ordering please specify Double, Left or Right. M & B dimensions must be measured from the bottom of the fitting. N = non-stock item – contact customer service for availability. 26 Multi-Story Fittings PART NO. EZS 400D Detail Drawing 4x30 Closet Fitting Double - M Inlet 0 B Inlet 61⁄2” 5-1/2” MIN. FINISHED FACE OF WALL HIDDEN LINE INDICATES EXTENSION OF 4” WASTE PIPING FINISHED FACE OF WALL INTEGRAL 2” VENT STACK FITTING FLOOR MOUNTED BOTTOM OUTLET TOILET FIXTURE FINISHED FLOOR FINISHED FLOOR SLAB 30” SLAB CLOSET FLANGE CLOSET BEND PER REQUIREMENTS CONTRACTOR SHALL USE PART NO. EZS 400D 4x30 CLOSET FITTING DOUBLE M INLET 0 B INLET 6-1/2” CLOSET FLANGE CLOSET BEND PER REQUIREMENTS INTEGRAL 2” INLET RIGHT SIDE DOUBLE FITTING IN-SLAB - LEFT SIDE ELEVATION 27 Multi-Story Fittings PART NO. EZS 700 Threaded Starter Fitting with or without 2” No-Hub Inlets (Double, Left Hand or Right Hand; Designed for use above the floor with back-outlet water closets; Double starter fittings have a baffle) (Photo Shows Left Hand) (Photo Shows Left Hand, Top View) FLOOR/CEILING (Photo Shows Double, Top View) A & B Dimensions must be measured from the top of the fitting. Part No. Size ABCDE Weight EZS 700D** 4x28 EZS 700D** 4x28 EZS 700D** 4x28 0 0 51⁄22861⁄240.0 1 0 8 ⁄251⁄22861⁄242.0 231⁄281⁄251⁄22861⁄242.0 EZS 700L EZS 700L EZS 700L EZS 700L 4x28 0 0 51⁄22861⁄234.6 4x28 0 81⁄251⁄22861⁄235.7 4x28 14 81⁄251⁄22861⁄236.3 4x28 231⁄281⁄251⁄22861⁄232.0 EZS 700R EZS 700R EZS 700R EZS 700R 4x28 4x28 4x28 4x28 0 0 51⁄22861⁄230.0 0 81⁄251⁄22861⁄234.0 14 81⁄251⁄22861⁄235.3 231⁄281⁄251⁄22861⁄232.0 **Double starter fitting has a baffle. 28 Multi-Story Fittings PART NO. EZS 700R Detail Drawing 4x28 Threaded Right Hand - A Inlet 0; B Inlet 0 with EZS 23 Trim Package 29 Multi-Story Fittings PART NO. EZS 700D Detail Drawing 4x28 Threaded Double - A Inlet 0; B Inlet 81⁄2” with EZS 22 Support Frame and EZS 24 Trim Package 30 Multi-Story Fittings PART NO. EZS 800 Threaded Starter Fitting with or without 2” No-Hub Inlets (Double, Left Hand or Right Hand; Designed for use above the floor with back-outlet water closets; Double starter fittings have a baffle) (Photo Shows Right Hand) (Photo Shows Right Hand, Top View) FLOOR/CEILING (Photo Shows Double, Top View) A & B Dimensions must be measured from the top of the fitting. Part No. Size A B C D E Weight EZS 800D** 4x28 EZS 800D** 4x28 16 16 0 5 ⁄2286 ⁄242.0 81⁄251⁄22861⁄242.0 EZS 800L EZS 800L 4x28 4x28 16 16 0 51⁄22861⁄235.4 81⁄251⁄22861⁄236.3 EZS 800R EZS 800R 4x28 4x28 16 16 0 51⁄22861⁄235.6 81⁄251⁄22861⁄235.3 1 1 **Double starter fitting has a baffle. Note: “O” dimension denotes the absence of the designated inlet. 31 Multi-Story Fittings PART NO. EZS 800L Detail Drawing 4x28 Threaded Left Hand - A Inlet 16; B Inlet 0 with EZS 22 Support Frame and EZS 24 Trim Package 32 Multi-Story Fittings PART NO. EZS 800D Detail Drawing 4x28 Threaded Double - A Inlet 16; B Inlet 0 with EZS 23 Trim Package 33 Multi-Story Fittings PART NO. EZS 710 No-Hub Starter Fitting with or without 2” No-Hub Inlets PART NO. EZS 810 No-Hub Starter Fitting with or without 2” No-Hub Inlets (Double, Left Hand or Right Hand; Designed for use above the floor with back-outlet water closets; Double starter fittings have a baffle) (Double, Left Hand or Right Hand; Designed for use above the floor with back-outlet water closets; Double starter fittings have a baffle) (Photo Shows Left Hand) (Photo Shows Left Hand, Top View) (Photo Shows Left Hand) (Photo Shows Double, Top View) (Photo Shows Double, Top View) FLOOR/CEILING FLOOR/CEILING A & B Dimensions must be measured from the top of the fitting. A & B Dimensions must be measured from the top of the fitting. Part No. Size EZS 710D** 4x28 EZS 710D** 4x28 EZS 710D** 4x28 A B C D E Weight 0 0 5 ⁄2 284 43.0 0 81⁄251⁄2 284 43.0 231⁄281⁄251⁄2 284 43.0 1 EZS 710L EZS 710L EZS 710L EZS 710L 4x28 0 0 5 ⁄2 284 36.6 4x28 0 81⁄251⁄2 284 36.6 4x28 14 81⁄251⁄2 284 36.6 4x28 231⁄281⁄251⁄2 284 36.6 EZS 710R EZS 710R EZS 710R EZS 710R 4x28 0 0 51⁄2 284 36.6 4x28 0 81⁄251⁄2 284 36.6 4x28 14 81⁄251⁄2 284 36.6 4x28 231⁄281⁄251⁄2 284 36.6 1 **Double starter fitting has a baffle. 34 (Photo Shows Left Hand, Top View) Part No. Size EZS 810D** 4x28 EZS 810D** 4x28 A 16 16 B C D E Weight 0 5 ⁄2286 ⁄243.0 81⁄251⁄22861⁄243.0 1 1 EZS 810L EZS 810L 4x28 16 0 51⁄22861⁄236.6 4x28 16 81⁄251⁄22861⁄236.6 EZS 810R EZS 810R 4x28 4x28 16 16 0 51⁄22861⁄236.6 1 8 ⁄251⁄22861⁄236.6 **Double starter fitting has a baffle. Note: “O” dimension denotes the absence of the designated inlet. Multi-Story Fittings PART NO. EZS 22 Trim Package, Support Frame Assembly (Weight capacity for the EZS 22 Support Frame is 500 pounds maximum.) 1—FRAME 1—LEFT LEG 1—RIGHT LEG 1—SUPPORT LEG (used for single only) 5—1⁄2 ” x 11⁄4 ” BOLTS 5—1⁄2 ” FLAT WASHERS (Illustration Shows Front of Frame) (Illustration Shows Side of Frame) (Illustration Shows Front of Frame) (Illustration Shows Front View) EZS 22 Extended Leg (Left or Right) (Illustration Shows Side View) EZS 22 Support Leg (Illustration Shows Side View) 35 Multi-Story Fittings PART NO. EZS 24 Trim Package, Wall-Hung Back-Outlet Assembly (To be used with PART NO. EZS 22 Support Frame Assembly) 1—4” PVC Sch. 80 NIPPLE with TEST CAP 1—BOWL GASKET 4—5⁄8 ” x 12” RODS 4—5⁄8 ” CHROME CAP NUTS 8—5⁄8 ” JAM NUTS 4—5⁄8 ” FLAT WASHERS 4—5⁄8 ” FIBER WASHERS 3—3⁄8 ” x 11⁄2 ” BOLTS FOR FACEPLATE 3—3⁄8 ” FLAT WASHERS 4—5⁄8 ” STAR WASHERS EZS 22 and EZS 24 Installation Instructions Exploded View of Support Assembly Hardware 1.Identify the major components of the EZS 24 Trim Package and EZS 22 Support Frame. 2.Secure EZS 22 Support Frame to installed starter fitting using 3⁄8” x 1 ½” bolts and 3⁄8” flat washers. 3.Secure right and left legs to the EZS 22 faceplate using ½” x 1 ¼” bolts and ½” flat washers in position shown to the right. 4.Adjust assembly to the desired height. Level and align the assembly. 5.Secure the feet of the EZS 22 Support Frame to the floor using the ½” x 1 ¼” bolts supplied. 6.Secure support leg. For double starter fittings, the support leg is not required. 7.Secure ⁄8” x 12” EZS 24 thread rods to faceplate according to EZS 22 faceplate. 5 8.Install EZS 24 threaded nipple to the EZS 700 or EZS 800 fitting. 36 EZS 22 and EZS 24 Assemblies Illustrated Multi-Story Fittings PART NO. EZS 23 Trim Package, Floor-Mounted Back-Outlet Assembly (Note: Not to be used with PART NO. EZS 22 Support Frame Assembly) 1—4” PVC Sch. 80 NIPPLE with TEST CAP 1—BOWL GASKET 2—5⁄16 ” x 12” RODS 2—5⁄16 ” HEX NUTS 2—5⁄16 ” FLAT WASHERS 2—5⁄16 ” CAP NUTS PART NO. EZS 800D Typical Installation NH 28 EZS 7L EZS 16 NH 4 Long Vent NH 34 18 42 EZS 14 EZS 38 EZS 800D NH 12 EZS 9 37 Multi-Story Fittings Hubless Application Index Fixture Type CPF Fitting Support Frame (If Applicable) Wall Hung, Back Outlet EZS 700 EZS 22 EZS 800 EZS 22 Starter Fitting is designed to be installed with inlet above floor level Floor Mounted, Back Outlet EZS 700 EZS 710 Starter Fitting is designed to be installed with inlet above floor level EZS 800 EZS 810 Floor Mounted, Bottom Outlet EZS 6 EZS 8 Starter Fitting is designed to be EZS 50 installed with inlet either in or EZS 51 below floor level EZS 100 EZS 400 EZS 457 EZS 458 EZS 463 EZS 464 38 Trim Package (If Applicable) EZS 24 EZS 24 EZS 23 EZS 23 EZS 23 EZS 23 Multi-Story Fittings Minimum Space Requirements for EZS 700 and EZS 800 Starter Fittings installed with EZS 22 Support Frame and EZS 24 Trim Package. (Note: EZS 22 Support Frame Assembly is not compatible with EZS 23 Trim Package.) EZS 700 and EZS 800 Double Starter Fittings EZS 700 and EZS 800 Left and Right Starter Fittings 7 3 /4” 11” Part No. Size A B C D E Weight EZS 700D 4x28 0 0 51⁄2 2861⁄240.0 EZS 700D 4x28 0 81⁄251⁄2 2861⁄242.0 EZS 700D 4x28 231⁄281⁄251⁄2 2861⁄242.0 EZS 800D 4x28 EZS 800D 4x28 16 16 0 51⁄2 2861⁄242.0 81⁄251⁄2 2861⁄242.0 Part No. Size A B C D E Weight EZS 700L EZS 700L EZS 700L EZS 700L 4x28 0 0 51⁄2 2861⁄234.6 4x28 0 81⁄251⁄2 2861⁄235.7 4x28 14 81⁄251⁄2 2861⁄236.3 4x28 231⁄281⁄251⁄2 2861⁄232.0 EZS 700R EZS 700R EZS 700R EZS 700R 4x28 0 0 51⁄2 2861⁄230.0 4x28 0 81⁄251⁄2 2861⁄234.0 4x28 14 81⁄251⁄2 2861⁄235.3 4x28 231⁄281⁄251⁄2 2861⁄232.0 EZS 800L 4x28 EZS 800L 4x28 16 16 0 51⁄2 2861⁄235.4 81⁄251⁄2 2861⁄236.3 EZS 800R 4x28 EZS 800R 4x28 16 16 0 51⁄2 2861⁄235.6 81⁄251⁄2 2861⁄235.3 39 Multi-Story Fittings Multi-Story Service Fittings Typical installation shows single back-outlet water closet and double-sink applications. MULTI-STORY INSTALLATION ➀ SV 1739 Left Hand Vented Closet Tee with 2” 45° Taps ➁ SV 1801 2x2x2 Tapped Harp Fitting ③ SV 83 5x2 Straight Tapped Tee ④ 5x10 SV Single Hub Pipe ➄ 4x10 SV Single Hub Pipe SV 206 4x4x18 Tapped Closet Bend with Southern Code Brass Plug MULTI-STORY INSTALLATION ➀ SV 581 4x2x2 Double Sink Stack — 1770 ➁ SV 83 3x2 Straight Tapped Tee ③ 3x10 Single Hub Pipe ④ 4x10 Single Hub Pipe All products manufactured by Charlotte Pipe and Foundry Company are proudly made in the U.S.A. 40 Multi-Story Fittings Multi-Story Tapped Service Fittings PART NO. SV 83 Straight Tapped Tee Size E’ G PART NO. SV 89 Long Sanitary Tapped Tee X Weight 2 x 11⁄22 61⁄48 5.5 2 x 2 2 61⁄48 6.0 3 x 11⁄221⁄27 9 7.4 3 x 2 21⁄27 9 8.5 4 x 2 3 7 9 12.3 4 x 3 4 8 11 14.0 4 x 4 3 7 9 15.0 5 x 2 31⁄27 9 13.5 5 x 4 31⁄281⁄21217.9 6 x 4 41⁄49 1324.4 PART NO. SV 84 Sanitary Tapped Tee Size 2 x 2 x 18 E’ G X Weight 3 ⁄166 ⁄418 8.8 1 1 PART NO. SV 91 Sanitary Tapped Cross Size E’ G X 2 x 11⁄2213⁄1661⁄4 2 x 2 31⁄1661⁄4 3 x 2 39⁄167 4 x 2 41⁄167 Weight 86.4 86.7 9 9.0 911.6 PART NO. SV 206 Tapped Closet Bend with Southern Code Brass Plug Size E’ G X Weight 2 x 11⁄2213⁄1661⁄4 86.0 2 x 2 31⁄1661⁄4 85.8 3 x 11⁄235⁄167 9 8.0 3 x 2 39⁄167 9 8.1 4 x 11⁄2313⁄167 9 10.3 4 x 2 41⁄16 7 9 11.7 4 x 3 41⁄16 8 1113.6 Size 31⁄2 x 4 x 4 x 18 A 18 BWeight 4 17.4 41 Multi-Story Fittings PART NO. SV 985 Tapped Bath Vent Wye PART NO. SV 566 Tapped Long Sweep Tee Size A 2 x 2 B C D Weight 51⁄231⁄8455⁄86.2 PART NO. SV 982 Tapped By-Pass Vent Fitting (Side View) Size 2 x 2 (Top View) Size 2 x 2 42 A 18 B 10 C D E F Weight 61⁄231⁄23 51⁄411.3 A B C D Weight 41⁄165 31⁄421⁄28.4 HOW TO DETERMINE RIGHT or LEFT HAND CLOSET FITTING To determine if whether a closet fitting is a right hand or left hand configuration, stand the fitting up with the closet inlet facing you. If the opening is on your left, it is a Left Hand fitting. If the opening is on your right, it is a Right Hand fitting. Right Hand and Left Hand configurations do not apply for Double fittings. (Right Hand Closet Fitting Illustrated) Multi-Story Fittings Multi-Story Service Fixture Fittings PART NO. SV 458 Vented Closet Tee with 2” Top Vent and 2” Extended Side Inlet PART NO. SV 459D Vented Closet Cross with 2” Top Vent and 2” Extended Side Inlet (Right Hand or Left Hand; Designed for use below the floor; Fitting does not require a baffle) (Designed for use below the floor; Fitting does not have a baffle) (Photo Shows Right Hand) Size 4x4x2x2x4 RH 4x4x2x2x4 LH (Photo Shows Right Hand, Top View) A B 11 11 C D EWeight 41⁄253⁄1649⁄1643⁄1637.0 41⁄253⁄1649⁄1643⁄1637.8 PART NO. SV 460 Vented Closet Tee with 2” Top Vent (Right Hand or Left Hand; Designed for use below the floor; Fitting does not require a baffle) (Photo Shows Left Hand) Size 4 x 4 x 2 x 4 RH 4 x 4 x 2 x 4 LH 4 x 4 x 2 x 2 x 4 A B 11 CWeight 61⁄443⁄447.0 PART NO. SV 463D Vented Closet Cross with 2” Top Vent and 2” Extended Side Inlet (Designed for use below the floor; Fitting does not have a baffle) (Photo Shows Left Hand, Top View) A B 11 11 Size C Weight 4 ⁄25 ⁄1635.0 41⁄253⁄1635.0 1 3 Size 4 x 4 x 2 A 11 B C Weight 6 ⁄44 ⁄443.8 1 3 43 Multi-Story Fittings PART NO. SV 581 Double Sink Stack-1770 PART NO. SV 581 Double Sink Stack-1770 (Designed for use above the floor) (Designed for use above the floor) 3x2x2 4x2x2 (Photo Shows Top View) Size 3 x 2 x 2 44 A B (Photo Shows Top View) Weight Size 123⁄441⁄265⁄841⁄253⁄418.0 C D E 4 x 2 x 2 A B C D Weight 121⁄2 571⁄241⁄221.4 Multi-Story Fittings PART NO. SV 581 Double Sink Stack Fitting (Designed for use above the floor) 4x2x2 WASTE STACK DISPOSAL VENT SINK VENT VENT STACK COUNTERTOP DOUBLE BOWL SINK CONTRACTOR SHALL USE PART NO. SV 900 GASKET OR OPTIONAL LEAD & OAKUM P-TRAP (TYPICAL) IN WALL WASTE CONTRACTOR SHALL USE PART NO. SV 581 DISPOSAL FINISHED FLOOR DOUBLE SINK STACK FITTING - FRONT ELEVATION 45 Multi-Story Fittings PART NO. SV 1739R Right Hand Vented Closet Tee with 2” 45° Taps PART NO. SV 1739L Left Hand Vented Closet Tee with 2” 45° Taps (Designed for use above the floor) (Designed for use above the floor) (Photo Shows Top View) (Photo Shows Top View) 2” Tap Size AB CD E F GWeight 4 x 2 x 4 x 2 18 63⁄4 81⁄4 45⁄8 35⁄8 41⁄2 23⁄451.1 46 Size 2” Tap AB CD E F GWeight 4 x 2 x 4 x 2 18 63⁄4 81⁄4 45⁄8 35⁄8 41⁄2 23⁄451.0 Multi-Story Fittings PART NO. SV 1739D Vented Closet Cross with 2” 45° Taps PART NO. SV 1801 2x2x2 Tapped Harp Fitting (Designed for use above the floor) 2” Tap (Photo Shows Top View) 2” Tap 2” Tap 2” Tap Size AB CD E F GWeight 4 x 2 x 4 x 2 18 63⁄4 81⁄4 45⁄8 35⁄8 41⁄2 23⁄457.5 Size 2 x 2 x 2 A B C Weight 117⁄162 35⁄815.5 47 Multi-Story Fittings PART NO. SV 1739L with SV 1801 SV 1739L Left Hand Vented Closet Tee with SV 1801 Harp Fitting Use with Floor Mounted Bottom Outlet Water Closet CONTRACTOR SHALL USE PART NO. SV 83 CONTRACTOR SHALL USE PART NO. SV 1801 4” SV CAST IRON PIPE VENT LINE LAVATORY 2” THREADED COPPER OR STEEL PIPE 4” SV CAST IRON PIPE DRAIN LINE TUB FINISHED FLOOR CONTRACTOR SHALL USE PART NO. SV 206 TAPPED CLOSET BEND WITH SOUTHERN CODE BRASS PLUG CONTRACTOR SHALL USE PART NO. SV 1739L VENTED CLOSET TEE WITH 2” 45° TAPS FRONT ELEVATION 48 P-TRAP (TYPICAL) Multi-Story Fittings Multi-Story Service Starter Fittings PART NO. SV 973R Right Hand Starter Fitting with 4” Tap and 2” Tapped “A” Side Inlet PART NO. SV 973L Left Hand Starter Fitting with 4” Tap and 2” Tapped “A” Side Inlet (Designed for use above the floor with back-outlet water closets) (Designed for use above the floor with back-outlet water closets) (Photo Shows Top View) (Photo Shows Top View) INLET A 6 1⁄2 9 1⁄2 INLET A 6 1⁄2 9 1⁄2 NOTES: 1. Single Vertical R.H. Offset Back Outlet Starter Fitting 2.4”Stack with 2”Vent & Inlets 3. Face Plate Package Not Included Size Inlet A B C D E NOTES: 1. Single Vertical L.H. Offset Back Outlet Starter Fitting 2.4”Stack with 2”Vent & Inlets 3. Face Plate Package Not Included F X Weight 4 61⁄2 See Chart 61⁄24 41⁄16442534.8 4 91⁄2 See Chart 61⁄24 41⁄16442534.4 Size Inlet A BCD EFXWeight 4 61⁄2 See Chart 61⁄244 442539.2 4 91⁄2 See Chart 61⁄244 442539.0 49 Multi-Story Fittings PART NO. SV 974R Right Hand Starter Fitting with 4” Hub and 2” Tapped “A” Side Inlet PART NO. SV 974L Left Hand Starter Fitting with 4” Hub and 2” Tapped “A” Side Inlet (Designed for use above or in the floor with back-outlet or bottom-outlet water closets) (Designed for use above or in the floor with back-outlet or bottom-outlet water closets) (Photo Shows Top View) (Photo Shows Top View) INLET A 6 1⁄2 Size ABC DE FX Weight 4 with A inlets 61⁄261⁄261⁄241⁄164 425 39.2 50 INLET A 6 1⁄2 Size ABC DE FX Weight 4 with A inlets 61⁄261⁄261⁄2 4 441⁄1625 39.7 Multi-Story Fittings PART NO. SV 974R Right Hand Starter Fitting with 4” Hub and 2” Tapped “A” and “B” Side Inlets PART NO. SV 974L Left Hand Starter Fitting with 4” Hub and 2” Tapped “A” and “B” Side Inlets (Designed for use above or in the floor with back-outlet or bottom-outlet water closets) (Designed for use above or in the floor with back-outlet or bottom-outlet water closets) FLOOR/CEILING Size 4 with A & B inlets FLOOR/CEILING NOTES: 1. Single Vertical R.H. Offset Floor Starter Fitting 2.4” Stack with 2” Vent & Inlets 3. Face Plate Package Not Included NOTES: 1. Single Vertical R.H. Offset Floor Starter Fitting 2.4” Stack with 2” Vent & Inlets 3. Face Plate Package Not Included INLET A B 61⁄218 INLET A B 61⁄218 A B C D XWeight 61⁄218 61⁄261⁄2 2546.2 Size 4 with A & B inlets A B C D XWeight 61⁄218 61⁄261⁄22543.7 51 Multi-Story Fittings PART NO. SV 974R with SV 900 CHARLOTTE SEAL GASKET 14-1/2” MIN. FINISHED FACE OF WALL HIDDEN LINE INDICATES EXTENSION OF 4” WASTE PIPING FINISHED FACE OF WALL INTEGRAL 2” VENT STACK FITTING CONTRACTOR SHALL USE PART NO. SV 900 GASKET FLOOR MOUNTED BOTTOM OUTLET TOILET FIXTURE FINISHED FLOOR 25” CONTRACTOR SHALL USE PART NO. SV 974R HUB STARTER FITTING FLANGE 4” PIPE 5/16” THREADED ROD - (TAP IN FITTING) INTEGRAL 2” THREADED INLET (BOTH SIDES) RIGHT HAND FITTING - LEFT SIDE ELEVATION 52 Multi-Story Fittings PART NO. SV 975 Double Starter Fitting with 4” Tap and 2” Tapped “A” Side Inlets (Designed for use above the floor with back-outlet water closets; Fitting has a baffle) Cast Iron pipe and fittings are only intended for DWV (drain, waste and vent) non-pressure applications. Using cast iron pipe and fittings in pressure applications could result in explosive failures, causing serious injury or death or property damage. (Gray Area Indicates Baffle) (Photo Shows Top View) Testing with or use of compressed air or gas in Cast Iron pipe or fittings can result in explosive failures and cause severe injury or death. • NEVER test with or transport/store compressed air or gas in Cast Iron pipe or fittings. • NEVER test Cast Iron pipe or fittings with compressed air or gas. • ONLY use Cast Iron pipe and fittings for drain, waste and vent or sanitary sewer applications. Unsecured piping can fall and cause serious injury. Always properly support and secure piping to help prevent injury. Always wear protective clothing, including hard hats, during installation. INLET A 9 1⁄2 Size 4 A B C D E F X Weight 9 ⁄26 ⁄24444 ⁄162542.5 1 1 1 53 Multi-Story Fittings PART NO. SV 976 Double Starter Fitting with 4” Hub and 2” Tapped “A” Side Inlet PART NO. SV 976 Double Starter Fitting with 4” Hub and 2” Tapped “A” and “B” Side Inlets (Designed for use above or in the floor with back-outlet or bottom-outlet water closets; Fitting has a baffle) (Designed for use above or in the floor with back-outlet or bottom-outlet water closets; Fitting has a baffle) (Gray Area Indicates Baffle) (Photo Shows Top View) (Gray Area Indicates Baffle) INLET A B 61⁄218 INLET A 6 1⁄2 Size A B C D E F XWeight 4 with A inlets 61⁄261⁄261⁄24 4 41⁄162550.8 54 Size A B C D E XWeight 4 with A & B inlets 61⁄21861⁄261⁄241⁄1625 56.6 Multi-Story Fittings Service Weight Application Index Fixture Type CPF Fitting Wall Hung, Back Outlet Starter Fitting is designed to be installed with inlet above floor level Floor Mounted, Back Outlet Starter Fitting is designed to be installed with inlet above floor level Floor Mounted, Bottom Outlet Starter Fitting is designed to be installed with inlet either in or below floor level SV 973 SV 975 Support Frame (If Applicable) Trim Package (If Applicable) EZS 22 EZS 22 EZS 24 EZS 24 SV 974 SV 976 SV 581 SV 1739 SV 458 SV 459D SV 460 SV 463D SV 1739 55 Multi-Story Fittings Minimum Space Requirements for Multi-Story Service Starter Fittings Tapped Service Fitting Illustrations Shown with EZS 22 Support Frame and EZS 24 Trim Package 11” 16” PART NO. SV 973R Right Hand Starter Fitting with 4” Tap PART NO. SV 975 Double Starter Fitting with 4” Tap Size Inlet Size A B C D E F X Weight 4 6 ⁄2 See Chart 6 ⁄24 4 ⁄16442534.8 4 91⁄2 See Chart 61⁄24 41⁄16442534.4 1 1 1 4 A A 1 C D E F X Weight 1 13 1 /2” PART NO. SV 973L Left Hand Starter Fitting with 4” Tap Size Inlet B 9 ⁄26 ⁄24444 ⁄162542.5 1 BCD EFXWeight 4 61⁄2 See Chart 61⁄244 442539.2 4 91⁄2 See Chart 61⁄244 442539.0 21” PART NO. SV 974R* Right Hand Starter Fitting with 4” Hub and A Inlets Size ABC DE FX Weight 4 with A inlets 61⁄261⁄261⁄241⁄164 425 39.2 PART NO. SV 974L Left Hand Starter Fitting with 4” Hub and A Inlets PART NO. SV 976* Double Starter Fitting with 4” Hub and A & B Inlets PART NO. SV 974R Right Hand Starter Fitting with 4” Hub and A & B Inlets Size A B C D E XWeight 4 with A & B inlets 61⁄21861⁄261⁄241⁄1625 56.6 PART NO. SV 976 Double Starter Fitting with 4” Hub and A Inlet Size A B C D E F 1 1 XWeight 1 *Above the floor installation for floor-mounted, back-outlet fixtures shown. Fitting can also be installed in the floor for floormounted, bottom-outlet water closets. 56 ABC DE FX Weight Size 4 with A & B inlets 4 with A inlets 6 ⁄26 ⁄26 ⁄24 4 4 ⁄162550.8 1 Size 4 with A inlets 61⁄261⁄261⁄2 4 441⁄1625 39.7 A B C D XWeight 61⁄218 61⁄261⁄2 2546.2 PART NO. SV 974L Left Hand Starter Fitting with 4” Hub and A & B Inlets Size 4 with A & B inlets A B C D XWeight 61⁄218 61⁄261⁄22543.7 Multi-Story Fittings Limited Warranty Charlotte Pipe and Foundry Company® (Charlotte Pipe®) Products are warranted to be free from manufacturing defects and to conform to currently applicable ASTM standards for a period of five (5) years from date of delivery. Buyer’s remedy for breach of this warranty is limited to replacement of, or credit for, the defective product. This warranty excludes any expense for removal or reinstallation of any defective product and any other incidental, consequential, or punitive damages. This limited warranty is the only warranty made by seller and is expressly in lieu of all other warranties, express and implied, including any warranties of merchantability and fitness for a particular purpose. No statement, conduct or description by Charlotte Pipe or its representative, in addition to or beyond this Limited Warranty, shall constitute a warranty. This Limited Warranty may only be modified in writing signed by an officer of Charlotte Pipe. 7) The Products fail due to the freezing of water in the Products. 8) The Products fail due to contact with chemical agents, fire stopping materials, thread sealant, plasticized vinyl products, or other aggressive chemical agents that are not compatible. 9) Pipe outlets, sound attenuation systems or other devices are permanently attached to the surface of Charlotte® PVC, ABS or CPVC products with solvent cement or adhesive glue. This Limited Warranty will not apply if: Charlotte Pipe products are manufactured to the applicable ASTM or CISPI standard. Charlotte Pipe and Foundry cannot accept responsibility for the performance, dimensional accuracy, or compatibility of pipe, fittings, gaskets, or couplings not manufactured or sold by Charlotte Pipe and Foundry. 1) The Products are used for purposes other than their intended purpose as defined by local plumbing and building codes, and the applicable ASTM standard. Any Charlotte Pipe products alleged to be defective must be made available to Charlotte Pipe at the following address for verification, inspection and determination of cause: 2) The Products are not installed in good and workmanlike manner consistent with normal industry standards; installed in compliance with the latest instructions published by Charlotte Pipe and good plumbing practices; and installed in conformance with all applicable plumbing, fire and building code requirements. Charlotte Pipe and Foundry Company Attention: Technical Services 2109 Randolph Road Charlotte, North Carolina 28207 3) This limited warranty does not apply when the products of Charlotte Pipe are used with the products of other manufacturers that do not meet the applicable ASTM or CISPI standards or that are not marked in a manner to indicate the entity that manufactured them. 4) In hubless cast iron installations, this warranty will not apply if products are joined with unshielded hubless couplings. Charlotte Pipe requires that its hubless cast iron pipe and fittings be joined only with shielded hubless couplings manufactured in accordance with CISPI 310, ASTM C 1277 and certified by NSF® International or with Heavy Duty Couplings meeting ASTM C 1540. 5) The Products fail due to defects or deficiencies in design, engineering, or installation of the piping system of which they are a part. 6) The Products have been the subject of modification; misuse; misapplication; improper maintenance or repair; damage caused by the fault or negligence of anyone other than Charlotte Pipe; or any other act or event beyond the control of Charlotte Pipe. Purchaser must obtain a return materials authorization and instructions for return shipment to Charlotte Pipe of any product claimed defective or shipped in error.Any Charlotte Pipe product proved to be defective in manufacture will be replaced F.O.B. point of original delivery, or credit will be issued, at the discretion of Charlotte Pipe. 4/24/15 Testing with or use of compressed air or gas in PVC / ABS / CPVC / Cast Iron pipe or fittings can result in explosive failures and cause severe injury or death. • NEVER test with or transport/store compressed air or gas in PVC / ABS / CPVC / Cast Iron pipe or fittings. • NEVER test PVC / ABS / CPVC / Cast Iron pipe or fittings with compressed air or gas, or air over water boosters. • ONLY use PVC / ABS / CPVC / Cast Iron pipe or fittings for water or approved chemicals. • Refer to warnings on PPFA’s website and ASTM D 1785. Charlotte and Charlotte Pipe are registered trademarks of Charlotte Pipe and Foundry Company. PO Box 35430 Charlotte, NC 28235 USA 704/348-6450 800/572-4199 www.charlottepipe.com FAX 800/553-1605 57 Multi-Story Fittings Notes 58 Multi-Story Fittings Notes 59 PO BOX 35430 CHARLOTTE NORTH CAROLINA 28235 PHONE (704) 348-6450 (800) 438-6091 FAX (800) 553-1605 LITERATURE BY FAX (800) 745-9382 WWW.CHARLOTTEPIPE.COM All products manufactured by Charlotte Pipe and Foundry Company are proudly made in the U.S.A.