Package Trends for Today`s and Future mm

advertisement

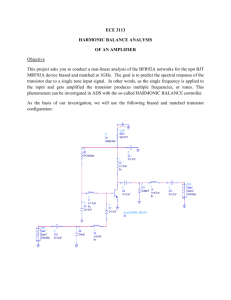

Package Trends for Today’s and Future mm-Wave Applications Maciej Wojnowski, Klaus Pressel, Grit Sommer, Mario Engl Outline Introduction Package Overview Thin Small Leadless Package (TSLP) Embedded Wafer-Level Ball Grid Arry (eWLB) Through Silicon Vias (TSV) Experimental Results Conclusion Page 2 Outline Introduction Package Overview Thin Small Leadless Package (TSLP) Embedded Wafer-Level Ball Grid Arry (eWLB) Through Silicon Vias (TSV) Experimental Results Conclusion Page 3 Introduction Increasing industrial demands Functionality (System Integration) Size Speed Cost & Time to Market Low/High Power Thermal Performance Reliability & Failure Analysis Page 4 Package Evolution Until Today and Towards Tomorrow 22 mm Functionality Functionality Ele Th ctric erm al P e al Pe rform Pin rfo Co rma ance un nc t e P-DIP Package Downsizing 13 mm P-TQFP 9,34 mm BGA Modules (SoB) P-TSOP I/II Chip Chip Scale Scale Package Package Flip-Chip Flip-Chip Packing Packing Size Size - in Package - on Board 1st Evolution 2nd Evolution THT SMD SMD (Peripheral) Grid Array (Area) 3rd Evolution System System Integration Integration System in Package SiP/SoP 3D-Packaging 4th Evolution Technology High performance Stacked Chips /3D Packaging Wafer Level Packaging Page 5 Packaging – Growing Challenges IC Chip – Peripheral Pad Pitch (100 Frontend Waferfab 30 µm) RFPerformance Package as Interposer Bridging the Electrical interface Thermal interface Size of component Interconnect Gap Cost Backend Production Shielding Interconnect Gap Customer Board (1000 Environmental protection Reliability & Signal interface Failure Analysis (Sensors) 500 µm) in special cases 400µm, but high board cost!! Customer Page 6 Semiconductor Development Impact on Packaging Wireless Automotive Analog/RF Medical More than Moore: Diversification Analog/RF Baseline CMOS: CPU, Memory, Logic More Moore: Miniaturization 2008 Logic DRAM Flash Co 90nm m bi n 65nm 32nm 22nm . . . V Sensors Actuators Biochips Interacting with people and environment 130nm 45nm HV Power Passives Information Processing Digital content System-on-chip (SoC) in g So Non-digital content System-in-package (SiP) C an d Si P: Hi gh er V al u e Sy st em s Beyond CMOS Page 7 Technology for System in Package: Infineon’s Technology Tree for BGA type MCM side-by-side passive integration Modules FC/ WB >1 die >2 dies F2F stacked die stacked embedded stacked package µ-FlipChip Si thru hole Increasing integration density WB/WB Pack. on Pack. Pack. on SiP eWLB Page 8 Trends in Packaging: System-in-Package Laminate based BGA Form Factor Interconnect Size, Cost Today Tomorrow L C Embedded Wafer Level BGA impedance-matched low loss TLs, integrated passives (L, C) Page 9 Outline Introduction Package Overview Thin Small Leadless Package (TSLP) Embedded Wafer-Level Ball Grid Arry (eWLB) Through Silicon Vias (TSV) Experimental Results Conclusion Page 10 Package Overview/Evolution THD through hole DIP, TO 220 SMD gull wing SO, QFP Dual Inline Plastic Package Small Outline Quad Flat Package Pitch: 2.54mm SMD solder balls BGA Ball Grid Array DSO-Pitch: 1.27mm Pitch: SSOP-Pitch: 1.5...1.27...1.0mm 0.65...0.5mm 0.8…0.65...0.5mm QFP-Pitch. [0.4…0,3] 0.8...0.65...0.5...0.4mm SMD leadless VQFN, TSLP Very thin Quad Flat No Lead Thin Small Leadless Package Pitch: 0.8, 0.65, 0.5 mm [0,4; staggered lands] Page 11 Technology Development & Package Development Processes Thinning and Dicing Die attach Wire bonding Flip chip in Package Molding Thin film technology WLP processes … Materials&Substrates Green Laminate substrates (xBGA) Leadframes (TSLP, UFLGA, VQFN, ...) Physics of Package Signal Integrity RF capability Heat dissipation Reliability Physics FA incl. adhesion Miniaturisation Power Methods/CCN Leadframe Packages Package Package Platforms Platforms Integration enabler System in Package QFP DSO TSSOP Leadless Package s QFN Laminate WLB BGA/SGA/LGA RF-Modules SG-WLB PG-eWLB Co-design Simulation&Modeling BDR Test KGD Standards Page 12 Outline Introduction Package Overview Thin Small Leadless Package (TSLP) Embedded Wafer-Level Ball Grid Arry (eWLB) Through Silicon Vias (TSV) Experimental Results Conclusion Page 13 The Leadless Package Concept TSLP TSLP – Thin Small Leadless Package Leadless package based on a leadframe concept Low to medium pin count (< 80 I/Os) Green package Wirebond and Flip-Chip capabilities Main advantages Small dimensions (few mm) Short interconnects Excellent RF capabilities Improved thermal performance Page 14 The Leadless Package Concept TSLP Die Au - Layer Cu Leadframe NiAu Contact 2a. Flip-Chip Bonding Ni - Bump 50 µm 1. Die Bonding 2b. Wirebonding 3. Molding 5. Singulation 4. Copper Removal and Final Plating 6. Electrical TestPage 15 The Leadless Package Concept TSLP Flexible leadframe concept Typical padsizes range from 100 µm to 300 µm Nearly arbitrary pad geometries ¬ Circular ¬ Rectangular ¬ … Improved thermal performance Power / GND supply Page 16 Wirebond Interconnects – Wire Length Variation 0 -5 -10 -20 -25 -30 0 -35 l = 1000 µm l = 600 µm l = 300 µm -40 -45 -1 -50 0 10 20 Frequency [GHz] 30 -2 40 S21 [dB] S11 [dB] -15 -3 -4 l = 1000 µm l = 600 µm l = 300 µm -5 -6 0 10 20 30 40 Frequency [GHz] Page 17 Wirebond Interconnects – Padsize Variation 0 -20 -30 0 w = 100 µm w = 200 µm w = 300 µm -40 -50 0 20 40 Frequency [GHz] 60 80 -2 S21 [dB] S11 [dB] -10 -4 w = 100 µm w = 200 µm w = 300 µm -6 0 20 40 60 80 Frequency [GHz] Page 18 Flip-Chip Interconnects – Padsize Variation 0 -10 -30 -40 0 w = 300 µm w = 200 µm w = 100 µm -50 -60 0 20 40 Frequency [GHz] 60 -1 80 S21 [dB] S11 [dB] -20 -2 w = 300 µm w = 200 µm w = 100 µm -3 0 20 40 60 80 Frequency [GHz] Page 19 Outline Introduction Package Overview Thin Small Leadless Package (TSLP) Embedded Wafer-Level Ball Grid Arry (eWLB) Through Silicon Vias (TSV) Experimental Results Conclusion Page 20 WLB Basic Platforms Fan-In / Fan-Out WLB Fan-In restricted to chip size WLB Fan-Out (eWLB) offers fan-out possibility SG-UFWLB-49 eWLB Test Vehicle WLB without WLB with redistribution layer WLBs Fan-In are chip size packages All balls must fit UNDER chip shadow • Number and pitch of Interconnects must be adapted to the chip size • Fan-in WLBs are available on market Package design of Fan-Out Package is INDEPENDENT from chip size: • Fan-out area adaptable to needs • No restrictions for ball pitch • Fan-Out WLB actually strongly in the focus of the market : Chip size : Package size Page 21 Schematic Process Flow for eWLB Package M. Brunnbauer, et al., “Embedded Wafer Level Ball Grid Array (eWLB),” 8th EPTC, Dec. 2006. Page 22 Transmission Lines in eWLB Techology CPW W/S = 87/20 µm Re Z0 = 49.2 Ω (Mold) Re Z0 = 42.8 Ω (Si 1-100 Ωcm) Mold (eWLB)/Si 1-100 Ωcm TFMSL W/T = 20/3 µm H = 10 µm BCB Re Z0 = 49.2 Ω (BCB) MSL Si 1-100 Ωcm W/T = 317/35 µm H = 130 µm Re Z0 = 46.9 Ω (RO3003) RO3003 Page 23 Transmission Lines cont. Measured performance eWLB eWLB Excellent performance of TMLs manufactured in eWLB Insertion loss 0.1 dB/mm @ 10GHz, 0.25 dB/mm @ 60GHz Page 24 Transmission Lines cont. Determination of charactersitic impedance of the CPW R ~ √f Line Parameters RLCG G ~ ωCtanδ tanδ = 0.017 (data-sheet = 0.026) Page 25 Transmission Lines cont. Separation of the electrical effects of the conductors and dielectrics where αC/αD = 90% αC/αD = 70% Further improvement of the performance of the transmission lines by applying low-loss thin-film dielectrics Page 26 Single-Layer Spiral Inductors Layout parameters Measured performance Page 27 Single-Layer Spiral Inductors cont. Measured performance Inductors in eWLB offer significantly better performance compared to inductors in standard on-chip technologies Page 28 MIM/Interdigital Inductors MIM capacitors Interdigital capacitors Page 29 MIM/Interdigital Inductors cont. Measured Performance Further improvement of the quality factor of the integrated capacitors by using low-loss thin-film dielectrics Page 30 Outline Introduction Package Overview Thin Small Leadless Package (TSLP) Embedded Wafer-Level Ball Grid Arry (eWLB) Through Silicon Vias (TSV) Experimental Results Conclusion Page 31 More fan out WLBs : Silicon Carrier Concept Silicon IC Die µFC interconnect Metal layer (Cu) Via hole Standard Solder Ball Dielectric layer Macro porous silicon Passive Si carrier with regular grid of TSV High integration density (Wafer technology for RDL) Passive integration of L and C High reliability interconnects IC and carrier (CTE match) Low cost concept (Standard circuit dies, cost optimized carrier concept) Page 32 Embedded Passives in Si Low Cost Technology Inductor Capacitor Planar L using of RDL for loops Si through hole via for inductor loops L = 0.5 − 35 nH Q = 20 − 25 Fres = 1 − 35 GHz MIM Caps using RDL for plates Trench Caps using Si – trough holes C = 35pF/mm2 Q = 500 – 2000 Fres= 1-20 GHz C = 3000pF/mm2 Q < 1000 Fres < 10 GHz Resistor No Resistor component in focus due to costs (missing specific material) Page 33 Coplanar Waveguide (CPW) over TSVs Measurement Grounded TSVs Floating TSVs HFSS Model Gnd Page 34 TFMSL and CPW over Floating TSVs Influence of TSVs Influence of TSVs Excellent performance of TMLs manufactured in SC Insertion loss 0.1 dB/mm @ 10GHz, 0.25 dB/mm @ 60GHz Page 35 Single/Double-Layer Spiral Inductors Single-layer inductors over floating TSVs Double-layer inductors over floating TSVs The inductors in SC offer significantly better performance compared to inductors in standard on-chip technologies Page 36 Influence of Floating/Grounded Configuration Single/double-layer inductors over floating TSVs vs. grounded TSVs Influence of TSVs ∆Q = 12 Grounding of TSVs Single-layer spiral inductor of L = 2.0 nH Page 37 3D Spiral Inductor The low quality factor is caused by the losses for the currents induced in TSVs distributed around the windings Page 38 Influence of Floating/Grounded Configuration 3D inductors over floating TSVs vs. grounded TSVs Influence of TSVs ∆Q = 15 Grounding of TSVs 3D spiral inductor of L = 5.6 nH Page 39 Outline Introduction Package Overview Thin Small Leadless Package (TSLP) Embedded Wafer-Level Ball Grid Arry (eWLB) Through Silicon Vias (TSV) Experimental Results Conclusion Page 40 17 GHz WLAN Receiver Fully assembled in TSLP-24 Package dimensions 3.5 mm x 3.5 mm Package height 400 µm Wirebond interconnect technology Au wirebonds 500 µm wirelength at critical RF output Approx. 400 pH parasitic inductance Inductance of the wirebonds used as external impedance matching network Page 41 17 GHz WLAN Receiver Polished cut image Mold Compound Chip Ni-Pad 400 µm 300 µm Rogers RO4003 Substrate Evaluation board Page 42 17 GHz WLAN Receiver Measured gain Two-tone measurement Page 43 80 GHz Voltage Controlled Oscillator Fully assembled in TSLP-24 Package dimensions 3.5 mm x 3.5 mm Package height 400 µm Total power consumption of 2 W Flip-Chip interconnect technology not possible Wirebond technology and die-attach to leadframe for efficient thermal management Wirebond interconnect technology Au wirebonds 300 µm wirelength at critical RF output 250 pH parasitic inductance Page 44 80 GHz Voltage Controlled Oscillator Page 45 80 GHz Voltage Controlled Oscillator 2.4 2.4 GHz GHz Output Output 19.125 19.125 GHz GHz Output Output 80 80 GHz GHz Output Output Page 46 80 GHz Voltage Controlled Oscillator Vss = 5.7 V Vss = 6 V (Core temp ≈ 100°C) (Core temp ≈ 100°C) VTUNE fVCO Output Power VTUNE fVCO Output Power 0V 75.07 GHz 5.45 dBm 0V 74.656 GHz 5.99 dBm 1V 79.136 GHz 5.75 dBm 1V 78.848 GHz 6.11 dBm 2V 80.384 GHz 6.67 dBm 2V 80.128 GHz 6.92 dBm 3V 81.088 GHz 6.4 dBm 3V 80.85 GHz 6.92 dBm 4V 81.536 GHz 5.83 dBm 4V 81.31 GHz 6.47 dBm 5V 81.888 GHz 5.6 dBm 5V 81.664 GHz 6.11 dBm Page 47 77 GHz SiGe Mixer Chip size 550 × 550 µm2 Gain G = 21.4 dB @ 77 GHz Noise Figure NFSSB = 11.8 @ 77 GHz Page 48 Package Design for 77 GHz SiGe Mixer Manufactured package family Package size 2.5 × 1.5 mm² and 2.0 × 1.5 mm² Full surface capability Standard pitch 0.5 mm Package P1X extremely short RF and LO signal paths (about 100 µm) Package P2X longer signal paths (about 360 µm) Three different RDL metallization profiles Page 49 77 GHz SiGe Mixer Gain and Noise Figure Measurements Page 50 TSV - RF Demonstrator on RF Test Board Fully functional & fully programmable RX & TX chain fully functional VCO locks on all channels Key RF parameters within spec limit Spurious performance need improvement Remark: No design of application optimization was done for the Si Carrier Demonstrator Page 51 TSV - RF Demonstrator : Cross Section Dimensions: 7,5mm x 8,0 mm Transceiver 2 Layer RDL Si Carrier µ-Bump 50 µm 2st Cu RDL Layer 1st Cu RDL Layer RDL VIA Dielectric Silicon Cu-Alloy Si-Through Contacts Copper FC Ball 250 µm Page 52 Outline Introduction Package Overview Thin Small Leadless Package (TSLP) Embedded Wafer-Level Ball Grid Arry (eWLB) Through Silicon Vias (TSV) Experimental Results Conclusion Page 53 Conclusion Thin Small Leadless Package Low cost solution based on leadframe concept Suited for low pin count applications Good RF performance for dedicated applications Embedded Wafer-Level Ball Grid Array Excellent RF capabilities High pin count Passive device integration capabilities Through Silicon Vias High interconnect density Passive device integration capabilities Page 54