read carefully

advertisement

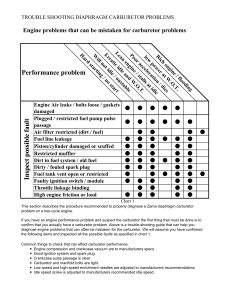

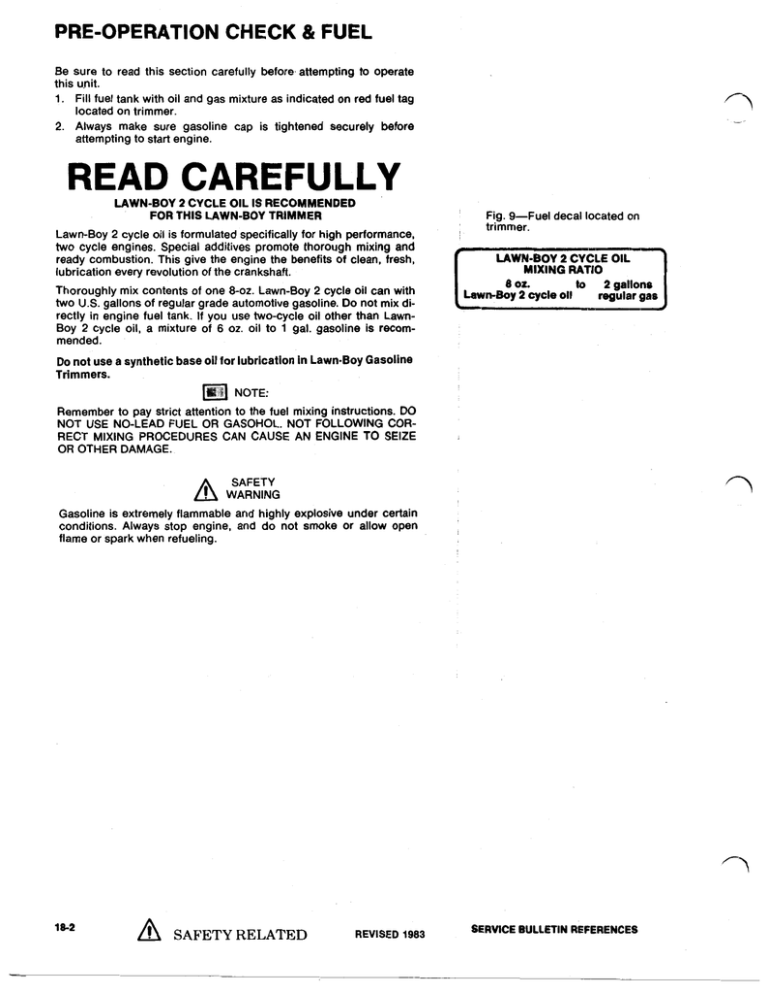

PRE-OPERATION CHECK & FUEL Be sure to read this section carefully before, attempting to operate this unit. 1. Fill fuel tank with oil and gas mixture as indicated on red fuel tag located on trimmer. 2. Alwaysmakesure gasoline cap is tightened securely before attempting to start engine. READ CAREFULLY LAWN-BOY 2 CYCLE OIL IS RECOMMENDED FOR THIS LAWN-BOY TRIMMER Lawn-Boy 2 cycle oil isformulated specifically for high performance, two cycle engines. Special additives promote thorough mixing and ready combustion. This give the engine the benefits of clean, fresh, lubrication every revolution of the crankshaft. Thoroughly mix contents of one 8-02. Lawn-Boy 2 cycle oil can with two U.S. gallons of regular grade automotive gasoline. Do not mix directly in engine fuel tank. If you use two-cycle oil other than LawnBoy 2 cycle oil, a mixture of 6 oz. oil to 1 gal. gasoline is recommended. Fig. 9-Fuel trimmer. decal located on LAWN-BOY 2 CYCLE OIL MIXING RATIO Lawn-Boy 2 cycleoilregular gas Do not use a synthetic baseoil for lubrication in Lawn-Boy Gasoline Trimmers. NOTE: Remember to pay strict attention to the fuel mixing instructions. DO NOT USE NO-LEAD FUEL OR GASOHOL. NOT FOLLOWING CORRECT MIXING PROCEDURES CAN CAUSE AN ENGINE TO SEIZE OR OTHER DAMAGE. Gasoline is extremely flammable and highly explosive under certain conditions. Always stop engine, and do not smokeorallow open flame or spark whenrefueling. 18-2 SAFETY RELATED REVISED 1983 SERVICE BULLETIN REFERENCES SERVICE BULLETIN REFERENCES 18-4 Low speed mixture adj. Metering lever 2 turns after contact with lever One 1-1/2 turn from seat (initially) .060-.070below carburetor body (metering cover gasket surface CARBURETOR WALBRO Idle speed TILLOTSON 1 turn from Beat Flush with carburetor metering chamber floor 3 turns after contact with lever SERVICE BULLETIN REFERENCES TROUBLE SHOOTING K AND CAUSE POSSIBLE STARTER ROPE WILL NOT REWIND Broken Starter Spring/Not enough Preload Replace Starter Spring Adjust tension per decal STARTER DOES NOT ENGAGE FLYWHEEL Broken Pawl Spring Broken Pawls or Pins Replace flywheel assembly ENGINE DIFFICULTOR WILL NOT START Fuel Tank empty Solid State weak. CHECK: Remove Spark Plug, reattach Plug Wire, hold Plug against engine and pull starter rope (a strong white spark should jump across plug points - weak Solid State produces a short red spark) Solid State grounded. CHECK: Wire from Solid State to “ON-OFF’’ Switch for bare spots. Carburetor misadjusted Engine flooded Engine is severely vapor locked Broken Reed Valve Fill FuelTank Replace C.D. Pack Wrap Wire with electrical tape or replace Re-adjustCarburetor Follow Starting Procedure WITHOUT USING CHOKE ALLOW TO COOL COMPLETELY Readjust Carburetor Replace CARBURETOR FLOODS Carburetor misadjusted Damaged Carburetor Diaphragm Leaking Gasket Leaking Inlet Needle Seat Readjust Carburetor Rebuild Carburetor with new kit. Rebuild Carburetor with new kit. Rebuild Carburetor with new kit. ENGINE WILL NOT IDLE Carburetor misadjusted Carburetor Diaphragm leaking Carburetor Inlet Seat Gasket leaking Crankshaft seals leaking Cylinder scored or compression low Reeds leaking or broken Head bound with grass Readjust Carburetor Replace Diaphragm Replace Gasket Replace seals Replace cylinder, piston and rings Replace reed valve Clean until free of grass ENGINE BACKFIRESOR MISFIRES Fuel Mix improper or contaminated Spark Plug fouled Solid State intermittently shorting. CHECK: loose or bare wires or loose assemblies Assembly Defective Reed Drain tank and refill with freshly mixed fuel Replace Spark Plug Tighten assemblies, wrap wires Replace HEAD WILL NOT TURN WHEN THROTTLE LEVERIS SQUEEZED Shaft broken Head Bound with grass Replace shaft Clean until free ENGINE WILL NOT ACCELERATE Carburetor misadjusted Dirty Air Filter Spark Plug fouled or Solid State weak Carbon build-up Carburetor Diaphragm Cover loose or Diaphragm Gasket leaking Broken Reed Valve Readjust Carburetor Clean Air Filter or replace Replace Spark Plug and regap or replace C.D. pack if we Clean Exhaust Port and Muffler Tighten all screws Replace ENGINE LACKSPOWER OR DIES IN THE CUT Dirty Air Filter Carbon build-up Low compression. CHECK: Compression pressure tests below 90 PSI or lessened engine resistance to pulling starter rope ADVANCE NOT WILL HEAD LINE Out of Line Bump Knob Bound Up Indexing Teeth Worn or Burred Head Dirty Line Welded Not Enough Line Exposed Clean Air Filter or replace Clean Exhaust Port and Muffler, page 18-6 Overhaul and rebuild engine Refill with Genuine Monoflail@Cutting Line Replace Replace Clean Disassemble remove welded section and rewind line per instructions Manually index until 4” or more of line shows outside the head 18-5