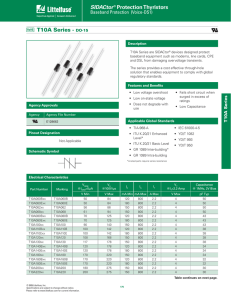

SIDACtor® Protection Thyristors SEP Biased Series

advertisement

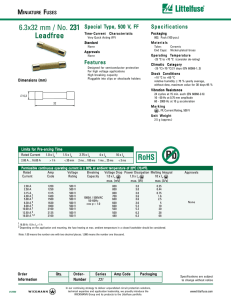

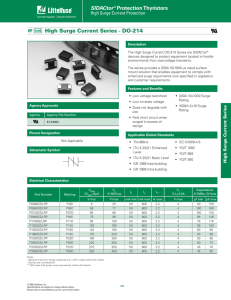

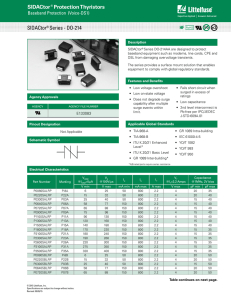

SIDACtor ® Protection Thyristors Broadband Optimized™ Protection SEP Biased Series - 5x6 QFN Description The new SEP (SIDACtor Ethernet/PoE Protector) series has a surge rating compatible with GR1089 Inter-building and ITU K.20/21 Enhanced protection requirements. Targeted for high-speed applications such as 10BaseT, 100BaseT, and 1000BaseT, the SEP series maintains signal quality while providing robust protection for Ethernet and PoE applications. This latest silicon design innovation results in a capacitive loading characteristic that is constant with respect to the voltage across the device. This reduces distortion caused by typical solid-state protection solutions. Offered in a surface-mount, QFN package, the SEP provides small package size without sacrificing power and surge handling capabilities. Agency Approvals Agency Agency File Number Features & Benefits E133083 t$PNQBUJCMFXJUI 1000Base-T Pinout Designation Line in 1 8 Line out - Bias Ground 2 7 3 6 + Bias Ground Line in 4 5 Line out (8) Line Out -Bias (2) t-PXQSPmMF t#BMBODFEPWFSWPMUBHF protection t4NBMM40GPPUQSJOU t-PXEJTUPSUJPO t'BJMTTIPSUDJSDVJUXIFO surged in excess of ratings Applicable Global Standards Schematic Symbol Line In (1) t-PXJOTFSUJPOMPTT (7) +Bias t5*"" t(3*OUFSCVJMEJOH t5*"# t(3*OUSBCVJMEJOH t*56,&OIBODFE Level t:%5 Ground (3) (6) Ground t*56,#BTJD-FWFM Line In (4) (5) Line Out t*&$ t:%5 t:%5 80 02 tcO snevaH pillihP Electrical Characteristics Part Number SEP0080Q38CB SEP0640Q38CB SEP0720Q38CB SEP0900Q38CB Marking SEP-8C SEP06C SEP07C SEP09C VDRM@ IDRM=5μA VS@100V/μs IH IS IT@VT VT@IT= 2.2Amps V min V max mA min mA max A max V max 6 58 65 75 25 77 88 98 50 150 150 150 800 800 800 800 2.2 2.2 2.2 2.2 8 8 8 8 Notes: - Absolute maximum ratings measured at TA= 25ºC (unless otherwise noted). - Devices are bi-directional (unless otherwise noted). © 2011 Littelfuse, Inc. Specifications are subject to change without notice. Please refer to www.littelfuse.com for current information. 53 Revised: February 22, 2011 Capacitance See Capacitance vs. Bias Voltage Graph SIDACtor ® Protection Thyristors Broadband Optimized™ Protection 50/60 Hz Ratings Parameter Name Test Conditions Value Units ITSM Maximum non-repetitive on-state current, 50/60 Hz 0.5s 1s 2s 5s 30s 900s 6.5 4.6 3.4 2.3 1.3 0.73 A Surge Ratings ITSM IPP Series C 2x10μs 1.2x50μs/8x20μs 10x700/5x310μs 10x1000μs 600VRMS 1 cycle A min A min A min A min ARMS 500 400 200 100 30 Notes: - Peak pulse current rating (IPP) is repetitive and guaranteed for the life of the product. - IPPSBUJOHTBQQMJDBCMFPWFSUFNQFSBUVSFSBOHFPG$UP$ - The device must initially be in thermal equilibrium with -40°C < TJ <¡$ Thermal Considerations Package 5x6 QFN Symbol Parameter Value Unit TJ Junction Temperature UP °C TSTG Storage Temperature Range UP °C R0JA Thermal Resistance: Junction to Ambient 100 °C/W V-I Characteristics Capacitance vs. Bias Voltage* +I 40 35 Bias Voltage IT 30 Capacitance (pF) IS IH IDRM -V +V VT VDRM 25 0V 3.3V 5V 12V 24V 30V 50V 20 15 10 VS 5 0 0.1 1 * Bias voltage must be lower than VDRM © 2011 Littelfuse, Inc. Specifications are subject to change without notice. Please refer to www.littelfuse.com for current information. 10 Line Voltage (V) -I 54 Revised: February 22, 2011 100 SIDACtor ® Protection Thyristors Broadband Optimized™ Protection Normalized DC Holding Current vs. Case Temperature 10 IH 8 6 25 °C 4 IH (TC = 25ºC) 2.0 14 12 2 0 -4 1.8 1.6 1.4 25°C 1.2 1.0 Ratio of Percent of VS Change – % Normalized VS Change vs. Junction Temperature 0.8 0.6 -6 0.4 -8 -40 -20 0 -40 20 40 60 80 100 120 140 160 -20 0 20 40 60 80 100 120 140 160 Case Temperature (TC) - ºC Junction Temperature (TJ) – °C Soldering Parameters - Temperature Min (Ts(min)) Pre Heat - Temperature Max (Ts(max)) - Time (Min to Max) (ts) Pb-Free assembly (see Fig. 1) ¡$ ¡$ 60-180 secs. Average ramp up rate (Liquidus Temp (TL) to peak) 3°C/sec. Max. TS(max) to TL - Ramp-up Rate 3°C/sec. Max. Reflow - Temperature (TL) (Liquidus) ¡$ - Temperature (tL) 60-150 secs. Peak Temp (TP) ¡$ Time within 5°C of actual Peak Temp (tp) 30 secs. Max. Ramp-down Rate 6°C/sec. Max. Time 25°C to Peak Temp (TP) 8 min. Max. Do not exceed ¡$ Figure 1 TP tP Critical Zone TL to TP Ramp-up Temperature Reflow Condition TL TS(max) tL Ramp-down Preheat TS(min) tS 25 time to peak temperature (t 25ºC to peak) Time Physical Specifications Environmental Specifications Lead Material Copper Alloy High Temp Voltage Blocking 80% Rated VDRM (VAC Peak ¡$PS¡$ 504 or 1008 hrs. MIL-STD-750 (Method 1040) JEDEC, JESD22-A-101 Terminal Finish 100% Matte-Tin Plated Temp Cycling Body Material UL recognized epoxy meeting flammability classification 94V-0 ¡$UP¡$NJOEXFMMVQUP cycles. MIL-STD-750 (Method 1051) EIA/JEDEC, JESD22-A104 Biased Temp & Humidity 52 VDC¡$ 3)VQUPIST&*" JEDEC, JESD22-A-101 High Temp Storage ¡$IST.*-45%.FUIPE JEDEC, JESD22-A-101 Low Temp Storage -65°C, 1008 hrs. Thermal Shock ¡$UP¡$NJOEXFMMTFDUSBOTGFS 10 cycles. MIL-STD-750 (Method 1056) JEDEC, JESD22-A-106 Resistance to Solder Heat ¡$TFDT.*-45%.FUIPE Moisture Sensitivity Level 3)¡$ISTSFnPXDZDMFT ¡$1FBL +&%&$+45%-FWFM © 2011 Littelfuse, Inc. Specifications are subject to change without notice. Please refer to www.littelfuse.com for current information. 55 Revised: February 22, 2011 SIDACtor ® Protection Thyristors Broadband Optimized™ Protection Dimensions — 5x6 QFN A 5 I B 6 H D 7 K L J E 4 3 I 2 F G PIN 1 INDICATOR PIN 1 & 8: LINE IN / LINE OUT PIN 2: BIAS (-) PIN 3 & 6: GROUND CONNECTIONS PIN 4 & 5: LINE IN / LINE OUT PIN 7: BIAS (+) C F (REF) G (REF) 5x6 QFN Solder Pad Layout .0200 Inches Dimension 8 .0500 Millimeters Min Max Min Max A 0.187 0.207 4.745 5.253 B 0.226 0.246 5.745 6.253 C 0.054 0.064 1.374 1.628 D 0.165 0.171 4.199 4.351 E 0.027 0.033 0.686 0.838 F 0.011 0.017 0.279 0.432 G 0.047 0.053 1.194 1.346 H 0.032 0.038 0.800 0.953 I 0.027 0.033 0.686 0.838 J 0.100 0.106 2.540 2.692 K 0.027 0.033 0.686 0.838 L 0.015 0.021 0.381 0.533 .2920 .2050 .1180 Part Marking Part Numbering SEP xxx 0 Q38 C B TYPE SIDACtor Ethernet Protector MEDIAN VOLTAGE XXXXXX BIASED Part Marking Code (Refer to Electrical Characteristics Table) IPP RATING XXXXX Date Code PACKAGE CONSTRUCTION VARIABLE Packing Options Package Type Description Quantity Added Suffix Industry Standard Q38 5x6x1.5 QFN Tape and Reel 4,000 N/A EIA-481-D © 2011 Littelfuse, Inc. Specifications are subject to change without notice. Please refer to www.littelfuse.com for current information. 56 Revised: February 22, 2011 SIDACtor ® Protection Thyristors Broadband Optimized™ Protection Tape and Reel Specifications — 5x6 QFN Reel Dimension Symbols A B C D N W1 A0 B0 D0 D1 E1 E2 C A D N W1 B Tape Leader and Trailer Dimensions END CARRIER TAPE START COVER TAPE F TRAILER 160mm MIN K0 P0 P1 LEADER 400mm MIN Tape Dimension Items D0 P0 P2 T CARRIER TAPE D1 T W B0 F E2 W W0 K0 P2 E1 P1 W0 A0 COVER TAPE © 2011 Littelfuse, Inc. Specifications are subject to change without notice. Please refer to www.littelfuse.com for current information. 57 Revised: February 22, 2011 Description Inches Millimeters Min Max Min Reel Diameter N/A 12.992 N/A Drive Spoke Width 0.059 N/A 1.50 Arbor Hole Diameter 0.504 0.531 12.80 Drive Spoke Diameter 0.795 N/A 20.20 Hub Diameter 1.969 N/A 50.00 Reel Inner Width at Hub 0.488 0.567 12.40 Pocket Width at Bottom 0.204 0.212 5.20 Pocket Length at Bottom 0.244 0.252 6.20 Feed Hole Diameter 0.059 0.063 1.50 Pocket Hole Diameter 0.059 N/A 1.50 Feed Hole Position 1 0.065 0.073 1.65 Feed Hole Position 2 0.400 0.408 10.15 Feed Hole Center 0.212 0.220 5.40 Pocket Hole Center 2 Pocket Depth 0.067 0.075 1.70 Feed Hole Pitch 0.153 0.161 3.90 Component Spacing 0.311 0.319 7.90 Feed Hole Center 0.077 0.081 1.90 Pocket Hole Center 1 Carrier Tape Thickness 0.010 0.014 0.25 Embossed Carrier 0.460 0.484 11.70 Tape Width Cover Tape Width 0.358 0.366 9.10 Max 330.0 N/A 13.50 N/A N/A 14.40 5.40 6.40 1.60 N/A 1.85 10.35 5.60 1.90 4.10 8.10 2.10 0.35 12.30 9.30