An Innovative Solution for High Hub Heights

Bolted Steel Shell Tower

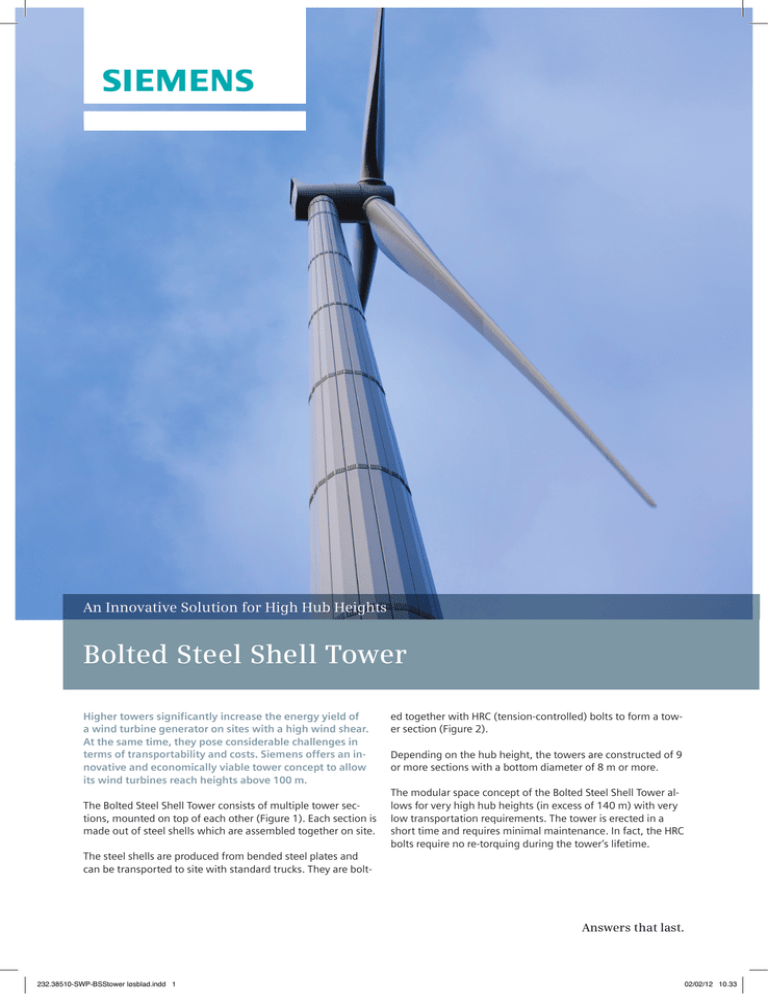

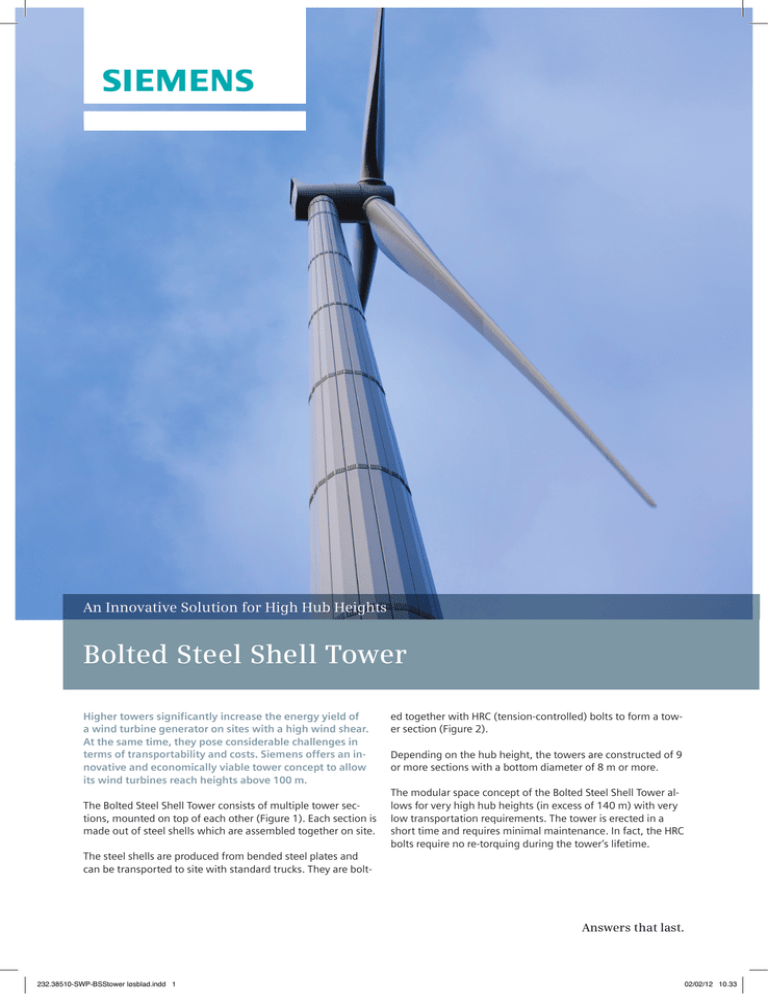

Higher towers significantly increase the energy yield of

a wind turbine generator on sites with a high wind shear.

At the same time, they pose considerable challenges in

terms of transportability and costs. Siemens offers an innovative and economically viable tower concept to allow

its wind turbines reach heights above 100 m.

The Bolted Steel Shell Tower consists of multiple tower sections, mounted on top of each other (Figure 1). Each section is

made out of steel shells which are assembled together on site.

ed together with HRC (tension-controlled) bolts to form a tower section (Figure 2).

Depending on the hub height, the towers are constructed of 9

or more sections with a bottom diameter of 8 m or more.

The modular space concept of the Bolted Steel Shell Tower allows for very high hub heights (in excess of 140 m) with very

low transportation requirements. The tower is erected in a

short time and requires minimal maintenance. In fact, the HRC

bolts require no re-torquing during the tower’s lifetime.

The steel shells are produced from bended steel plates and

can be transported to site with standard trucks. They are bolt-

Answers that last.

232.38510-SWP-BSStower løsblad.indd 1

02/02/12 10.33

The tower includes a lift and ladder to reach the nacelle. A transformer

unit can be installed within the tower. The door has standard dimensions

to allow for the exchange of internal components. The tower can be fitted

with aviation warning lights which can be bolted to the outside tower

wall at any horizontal section connection.

Figure 2. 3-D model and top-view of a tower section showing the steel shells

The Bolted Steel Shell Tower features the following key benefits:

• Virtually no restriction on the maximum hub height, as long as a

suitable crane is available

• Low steel requirement compared to tubular steel towers through the

combination of larger tower diameters, high-strength steel and

reduced material thickness

• The possibility to use steel coils which are cheaper than quarto steel

plates

• An automated shell production process which ensures high quality and

reduced costs

• Easy transportation of shells on standard trailers, in containers or by

rail, facilitating access to even remote locations

• Fast and easy installation using tension-controlled HRC bolts and preinstalled internals (tower erection within a couple of days)

• No welded connections which reduces the risk of errors and long-term

problems with fatigue and crack initiation

• Fully recyclable tower (material value is retained)

• No service maintenance of bolt connections necessary

• Effective corrosion protection, tower sealing and dehumidification

solutions

Product roadmap

• First prototype installed in May 2011

• Serial production in 2012

For more information, please contact

your Customer Support Center for your

local Siemens sales representative.

Published by and copyright © 2011:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Wind Power

Lindenplatz 2

20099 Hamburg, Germany

Customer Support Center

Phone: +49 180 524 70 00

E-mail: support.energy@siemens.com

All rights reserved.

Figure 1. Bolted Steel Shell

Tower with 9 sections

All rights reserved.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore

be specified in the contract.

Wind Power Division

Order no. E50001-E310-A193-X-4A00

siemens.com/wind

232.38510-SWP-BSStower løsblad.indd 2

02/02/12 10.33