Ambulance Patient Compartment Human Factors Design

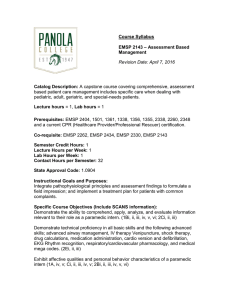

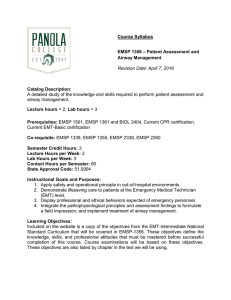

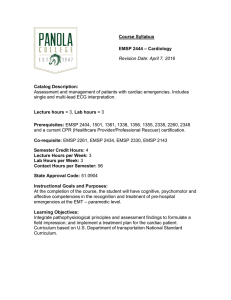

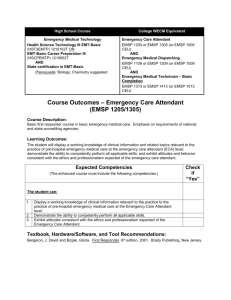

advertisement