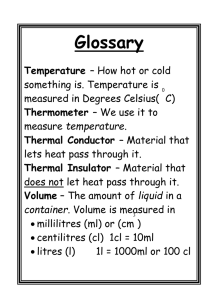

Physical Properties of Food Materials

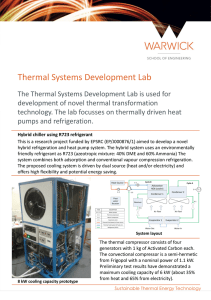

advertisement