copper penn-crimps - Penn

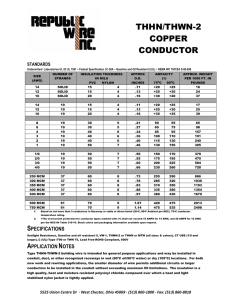

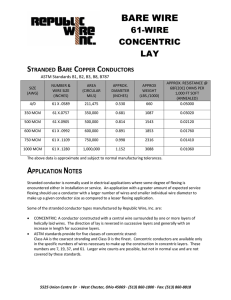

advertisement