Towards a Transparent, Highly Conductive Poly (3, 4

advertisement

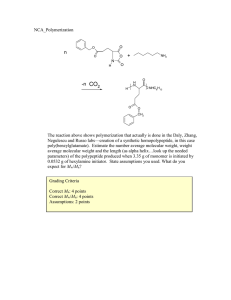

FULL PAPER Towards a Transparent, Highly Conductive Poly(3,4-ethylenedioxythiophene)** By Yung-Hoon Ha, Nikolay Nikolov, Steven K. Pollack, John Mastrangelo, Brett D. Martin, and Ranganathan Shashidhar* A detailed investigation of the processing parameters influencing the oxidative polymerization of 3,4-ethylenedioxythiophene (EDOT) and a methanol-substituted derivative (EDOT±CH2OH) was performed with the goal of maximizing the conductivity of the polymer. We show that the conductivity can be significantly enhanced by varying the monomer, oxidant (iron(III) p-toluenesulfonate (Fe(OTs)3)), weak base (imidazole (Im)), solvent (various alcohols), and solution concentrations. The effect of each variable on the final materials properties is investigated, and the parameters have been optimized to achieve conductivities as high as 900 S cm±1. Surface resistance below 150 X/& for 80±90 nm thick films with visible-spectrum transparency exceeding 80 % is achieved. The combination of these properties makes the films highly suitable for numerous device applications. 1. Introduction A= e c t The heralded discovery of a polymer which transports charge[1] has led to unprecedented excitement[2,3] over its possibilities for numerous wide-ranging sets of applications such as electrochromics,[4] supercapacitors,[5] antistatic and electrostatic coatings,[6] light-emitting diodes,[7±10] photovoltaics,[11,12] and sensors,[13] in addition to a host of other applications.[14±16] Most of these applications need materials with low surface resistances and high optical transparency, and have thus spurred on numerous research efforts to achieve a combination of these properties. In general, efforts at improving the conductivity were directed in controlling synthetic conditions,[17,18] altering the fundamental polymer backbone,[19,20] doping,[21] and/or functionalizing the backbone with substituent side groups.[22] For example, significant improvements in the conductivity of the materials were afforded by ªdopingº, where cations are inserted into the polymer backbone to aid in charge conduction, and metallic conductivities have been reported.[21] However, due to the highly conjugated nature of conducting oligomers/polymers, they are highly absorbing in the neutral undoped state and even more so in the doped state. The transparency of conducting polymers nominally follows Beer's law: where A is the total absorption, e is the molecular absorption, c is the concentration of the absorbing species, and t is the path length (thickness of the sample). Making thinner films will result in higher transparency, but generally leads to higher resistances. Moreover, the upper limit of transparency is dictated by the material itself due to the molecular absorption for different conducting polymers. Therefore, materials with low molecular absorption and high conductivity are required for the desirable combination of high transparency and low resistance. Among the numerous materials devised, the development of a polythiophene derivative, poly(3,4-ethylenedioxythiophene) (PEDOT; see Scheme 1 for structure), has shown significant promise to meet the challenges of competing properties.[14] PEDOT can be found in a variety of different forms. The most widely utilized is the commercialized blend of PEDOT with poly(styrenesulfonate), with reported film transparencies of ~ 80 % but low conductivities of approximately 10 S cm±1.[14] Electrochemical polymerization is also widely utilized but typi- (1) ± [*] Dr. R. Shashidhar,[+] Y.-H. Ha,[++] N. Nikolov, S. K. Pollack, J. Mastrangelo, B. D. Martin U.S. Naval Research Laboratory Center for Bio/Molecular Science and Engineering Washington, DC 20375 (USA) E-mail: rshashidhar@geo-centers.com [+] Present address: Geo-Centers, Maritime Plaza One, 1201M St. S.E. Suite #50, Washington, DC 20003, USA. [++] Present address: Oblon, Spivak et al., 1940 Duke St., Alexandria, VA 22314, USA. [**] We gratefully acknowledge Dr. Shi-Cheng Tony Wang's helpful and enthusiastic discussions and support in this work. Y.-H. Ha thanks the National Research Council for a postdoctoral fellowship. We gratefully acknowledge Office of Naval Research and DARPA for financial support. Adv. Funct. Mater. 2004, 14, No. 6, June Scheme 1. The chemical structures of 3,4-ethylenedioxythiophene (EDOT), 2,3-dihydrothieno[3,4-b][1,4]dioxin-2-yl methanol (EDOT± CH2OH) and 3,4-dihydro-2H-thieno[3,4-b][1,4]dioxepin-3-ol (ProDOT). DOI: 10.1002/adfm.200305059 2004 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim 615 FULL PAPER Y.-H. Ha et al./Towards a Transparent, Highly Conductive Poly(3,4-ethylenedioxythiophene) cally results in extremely poor transparency and small sample sizes despite the enhanced conductivity.[23,24] Potentially the most promising approach is to use the EDOT monomer, which can be oxidatively polymerized after spin-casting onto various different substrates. Conductivity values of 300 S cm±1 with high transparency have been reported.[6] However, a further improvement is needed for display applications. Towards this goal, many efforts, ranging from bandgap tuning through the use of substituted or derivatized PEDOT,[25,26] tailoring doping/dedoping conditions,[27,28] or careful control of the electrochemical polymerization conditions,[29±31] are currently underway. Surprisingly however, little effort[6,32±34] has been devoted thus far to manipulating the intrinsic process, namely oxidative polymerization, by which PEDOT is formed from the monomer. Also, the effect of derivatized EDOT in oxidative polymerization has not yet been explored. The oxidative polymerization of EDOT into a polymer is depicted in Scheme 2. The process utilizes iron(III) toluenesulfonate (Fe(OTs)3) as a stoichiometric oxidant and imidazole as a base for the attenuation of the Fe(OTs)3 oxidation potential, and is analogous to the oxidative polymerization of other conducting polymers. The rate-limiting step in this reaction is most likely the redox reaction between the FeIII compound and the monomer. Prior work ascribed the influence of an added base to a change in the pH of the reaction media and a concomitant change in the reduction potential of the FeIII/FeII couple.[6] Furthermore, the Fe(OTs)3 oxidizes the EDOT, transforming it into a cation radical that dimerizes and is rapidly stabilized by base-assisted removal of two protons. This base may be tosylate ion (OTs±) or free amine. Additional Fe(OTs)3 oxidizes the dimers, and chain growth proceeds as a classical step- polymerization. It also oxidizes the growing chains, leaving the PEDOT in its doped (conducting) state. However, no detailed study on the roles of individual components in the formation of PEDOT has been carried out, and a significant gap exists in the understanding the effect of numerous variables, such as base concentration, oxidizer/dopant concentration, types of solvents, and solution concentration, on the final material's properties. In this study we provide an explanation of the variables associated with oxidative polymerization of EDOT and its effect on the resultant material's properties (conductivity and transparency). Utilizing the understanding of the role of the various variables in controlling the materials properties, we describe an optimization process that form PEDOT films with conductivity of 750 S cm±1 (surface resistance of 270 X/& and 81 % transparency). Furthermore, these studies imply even further enhancement of the properties by the use of methanol-substituted EDOT. Indeed, we have used this approach to achieve conductivities of 900 S cm±1 (140 X/& surface resistance and 82 % transparency). 2. Results and Discussion 2.1. Understanding the Oxidative Polymerization of PEDOT 2.1.1. Effect of a Weak Base To test for the effect of a weak base, imidazole (Im) concentration was varied whilst fixing the molar ratio of the Fe(OTs)3/EDOT at 2:1. The reactants were dissolved in buta- Scheme 2. Schematic description of the oxidative step-growth polymerization of EDOT into PEDOT. Note the imidazole acts to reduce the reactivity of Fe(OTs)3 (FeIII) thereby leading to slower polymerization kinetics and lower doping levels. 616 2004 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim http://www.afm-journal.de Adv. Funct. Mater. 2004, 14, No. 6, June nol as a 30 wt.-% solution, which was spin-cast at 1500 rpm. Increasing the amount of Im leads to a dramatic increase in conductivity and transparency (see Fig. 1). a) FULL PAPER Y.-H. Ha et al./Towards a Transparent, Highly Conductive Poly(3,4-ethylenedioxythiophene) b) Figure 1. Imidazole increases the conductivity of PEDOT (squares), by simultaneously promoting higher molecular weight chains and preventing overdoping. Polymerized PEDOT films do not form when more than ~ 2.5 molar ratio of Im/EDOT is added. The conductivity of P(EDOT±CH2OH) (open circles) decreases above 2.5 molar ratio of Im/EDOT±CH2OH as Im probably becomes hydrogen bonded to the P(EDOT±CH2OH) backbone and dedopes the polymer. Data on surface resistance, transparency, and thicknesses for each PEDOT (boxes) and P(EDOT±CH2OH) (circles) sample are also included in the figure. de Leeuw et al.[6] attributed the effect of the added amine to increase in the pH of the reaction media, which in turn reduces the reactivity of the Fe(OTs)3. Indeed, our cyclic voltammograms show a systematic shift of the formal potentials to more negative voltages with increasing Im, demonstrating the lowered reactivity of the Fe(OTs)3 (Fig. 2a). This implies that, as the Im concentration increases, the reduction of FeIII, the critical reaction in the polymerization, becomes increasingly more difficult. However, the lowered reactivity may not be purely due to pH changes only. Spectroscopic studies indicate that Im actually coordinates with the Fe(OTs)3, as a shift in the absorption peak is observed with increasing Im concentration (see Fig. 2b). Since Fe(OTs)3 is initially hydrated, we interpret this shift as being due to successive substitution of Im replacing water or alcohol ligands that are initially present. Thus, we believe that the lowered reactivity, and thus a decrease in the polymerization kinetics, may not only be due to the pH changes induced by the addition of the base as originally postulated by de Leeuw et al., but also due to the coordination of Fe(OTs)3 with Im around its shell. This implies that a decrease in polymerization kinetics may arise because Im prefers to quench a monomer radical versus an oligomeric radical during the polymerization process. This is to be expected since the doped PEDOT radical cations are Adv. Funct. Mater. 2004, 14, No. 6, June Figure 2. a) The formal potential of Fe(OTs)3 decreases as a function of Im concentration. The lowered formal potential indicates a decrease in the reactivity of the Fe(OTs)3 thereby slowing the polymerization kinetics. b) Peak absorption wavelengths of Fe(OTs)3 shift with the addition of Im indicating ligation of Im to Fe(OTs)3, which may cause the decrease in Fe(OTs)3¢s formal potential. more delocalized in an oligomeric chain and thus have lower reactivity. Our observation implies that the polymerization kinetics are skewed toward longer chains with increasing Im content and Im preferentially quenches the monomeric EDOT radicals; additionally, the longer oligomers couple with each other leading to higher molecular weights. The longer chains allow larger orbital delocalization thus increasing the conductivity, which is demonstrated experimentally. Unfortunately, the insolubility of the PEDOT in any common organic solvents preclude the determination of the molecular weight of the samples with any of the techniques available to us. Additionally, it is important to note that this does not imply the consumption of the imidazole: namely, quenching of the EDOT radicals creates a positively charged imidazole that in turn reduces the FeII into the FeIII state, regenerating the initial Im and Fe(OTs)3 in the FeIII state. http://www.afm-journal.de 2004 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim 617 FULL PAPER Y.-H. Ha et al./Towards a Transparent, Highly Conductive Poly(3,4-ethylenedioxythiophene) Another significant factor is that the moderation of the FeIII activity by the amine probably prevents the chains from becoming overdoped, as the Fe(OTs)3 not only initiates the polymerization, but also oxidizes the growing chain (see Scheme 2). Soaking the conductive (doped) film (286 S cm±1) in a 2 M imidazole solution for 10 min does in fact lead to a significant decrease in conductivity (70 S cm±1) and the films turn violet, which is indicative of dedoping.[35] Mechanistically, the dedoping reaction must involve electron transfer from Im to the radical cation in the conducting polymer chain. Therefore, Im also acts as a reducing agent with respect to the doped polymer to prevent overdoping, which has important consequences for the conductivity and transparency of the resulting films, and will be explored further in the next section. The high reactivity without imidazole has another consequence. It leads to thicker films as oligomers (or polymers) may begin forming in solution prior to spin-casting. In fact, the reactivity of the Fe(OTs)3 is so high that the polymerization initiates (as evidenced by the change in film color toward a bluish hue) within 60 s, even at room temperature, after spin-casting without the presence of the imidazole. This has a detrimental effect on the transparency, as thicker samples lead to higher absorption and hence lower transparency. Additionally, the excessively fast polymerization kinetics also cause prepolymerized nanoscopic droplets to precipitate onto the substrate, causing high surface roughness. In contrast, the presence of the amine moderator preserves the EDOT in monomeric form after spincasting, and the polymerization at elevated temperature after spin-casting leads to smoother surface morphology with increasing connectivity between the domains (see Fig. 3). This not only leads to enhanced conductivity, but also enables achieving a smoother surface morphology which is particularly important for display devices. We have thus demonstrated that imidazole serves three major roles in this system: d it retards the polymerization kinetics by reducing the reactivity of Fe(OTs)3 either by coordination and/or lowering of the pH, d it promotes higher molecular weight polymeric/oligomeric chains, and it prevents the polymer from becoming overdoped. Thus, the presence of the imidazole increases transparency (by decreasing the path length and reducing the surface roughness) and the conductivity (by promoting higher molecular weights and preventing overdoping). d 2.1.2. Effect of Fe(OTs)3 To further illustrate the concept of overdoping, the Fe(OTs)3 concentration was varied whilst fixing the Im/EDOT ratio at 2:1. Again, a 30 wt.-% butanol solution was employed using a 1500 rpm spin speed. Samples containing a 1.5 molar ratio of Fe(OTs)3 did not polymerize, potentially due to a sub-stoichiometric quantity of the oxidizing agent or to the relative excess of the Im, which lowers the polymerization reactivity as discussed in the previous section. Increasing the Fe(OTs)3 content leads to polymerizable films, and a decrease in conductivity and transparency are observed (see Fig. 4). Both of these effects can be attributed to overdoping. The conductivity decrease is probably due to immobilized charge carriers, while the transparency decrease is due to thicker film formation caused by faster polymerization kinetics. In addition, the transparency decrease could also be due to a higher number of absorbing moieties as will be illustrated next. The dedoped sample from the previous section (recall the conductivity dropped to 70 S cm±1) was soaked in a saturated Fe(OTs)3 solution, and the conductivity increased to approximately 130 S cm±1 with a transparency of 72 %, which are both lower values than for the starting material (280 S cm±1 and 80 % transparency). These experiments confirm that although the Fe(OTs)3 is required for polymerization to occur and to dope the growing polymer chains, excess amounts of Fe(OTs)3 should be avoided to prevent overdoping, which decreases the transparency and the conductivity. 2.1.3. Effect of the Solvent The choice of solvent may also affect the final properties. Alcoholic solvents with higher boiling points should remain in Figure 3. AFM image showing the drastic differences in the surface roughness of sample containing zero (left) and two (right) molar ratio of Im where the Fe(OTs)3/EDOT ratio was fixed at 2:1. The reduction of polymerization kinetics induced by the addition of Im leads to significantly smoother surface roughness. 618 2004 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim http://www.afm-journal.de Adv. Funct. Mater. 2004, 14, No. 6, June Figure 4. The conductivity of PEDOT (squares) decreases with higher solution concentration of Fe(OTs)3 due to overdoping induced by excess Fe(OTs)3. The conductivity of P(EDOT±CH2OH) (open circles) reach a maximum as hydrogen-bonded Im dedopes at low concentrations of Fe(OTs)3, but eventually overdopes with excess Fe(OTs)3. The measured surface resistance, transparency, and thicknesses for each PEDOT (boxes) and P(EDOT±CH2OH) (circles) sample are included in the figure. the sample for a longer time during polymerization at 110 C and thus should lead to thinner (more transparent) films as the reactant concentration is kept relatively low during polymerization. Alternatively, the viscosity increase observed with higher boiling point solvents may retard polymerization kinetics. This implies a competition between these two factors in the case of lower boiling point solventsÐalthough the polymerization kinetics are faster (promoting longer chain formation), a high solvent evaporation rate may kinetically trap the polymerization at an early stage. The solvent was varied while fixing the Im/Fe(OTs)3/EDOT at a 2:2:1 molar ratio. Prior to spin-casting, a gradual color change with time (over ~ 1 h) is observed in solutions formed from the lower boiling point methanol, whereas solutions formed with the higher boiling point pentanol did not exhibit any noticeable color changes. This suggests EDOT oligomerization occurs in the lower viscosity solvents as discussed. Another interesting feature is that nearly constant conductivities are observed for all solvents despite the increase in film thickness for samples polymerized with lower boiling point solvents (see Fig. 5). This suggests that the two competing factors discussed previously are surprisingly balanced. Namely, the thickness is higher in lower boiling point solvents because more EDOT units are oligomerized in solution prior to spin-casting and attached to the surface, but the rapid evaporation rate of the solvent kinetically restricted the growing polymers to a certain chain length. This implies that if a higher probability of oligomer formation can be induced at fixed Im/Fe(OTs)3/ EDOT ratios, longer polymers should form, allowing higher conductivities to be realized. Adv. Funct. Mater. 2004, 14, No. 6, June FULL PAPER Y.-H. Ha et al./Towards a Transparent, Highly Conductive Poly(3,4-ethylenedioxythiophene) Figure 5. The PEDOT conductivity (squares) remains approximately constant, P(EDOT±CH2OH) conductivity (open circles) decreases with higher boiling point solvents. The higher polymerization kinetics is surprisingly balanced by the evaporation rate for different boiling point solvents for the PEDOT. Thus the conductivity remains constant but the thickness increases with decreasing boiling point solvents. Hydrogen bonding again plays a role for the P(EDOT±CH2OH), decreasing the conductivity with longer chain solvents, which prevents efficient packing. The measured surface resistance, transparency, and thicknesses for each PEDOT (boxes) and P(EDOT±CH2OH) (circles) sample are included in the figure. 2.1.4. Effect of Solution Concentration In light of the evidence from the previous section, the solution concentration and spin speed was varied by 15±45 %, using 2-methoxyethanol as the solvent. This effectively alters the overall reactant concentration drastically. Increase in the overall reactant concentration leads to a higher probability (rate) of chain propagation reaction, presumably leading to higher molecular weight chains and to higher conductivities. Additionally, thicker films will result due to higher viscosity, which decreases the transparency according to Beer's Law. Figure 6 shows that lowest solution concentration (15 %) leads to extremely thin films where the conductivity decreases with decreasing thickness. However, the conductivity is approximately 300 S cm±1 and 500 S cm±1 for all thicknesses measured at 30 % and 45 % solution concentration, respectively. The linear relationship of transparency with thickness again confirms that the film absorption follows Beer's Law, i.e., depends on film thickness only. On the other hand, the differences in the observed conductivity can be attributed to the higher molecular weights, as discussed previously, or to a different packing scheme. However, electron diffraction studies on these systems using transmission electron microscopy (TEM; not shown) indicate that there is no difference in the packing scheme of the chains due to different solution concentrations. http://www.afm-journal.de 2004 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim 619 FULL PAPER Y.-H. Ha et al./Towards a Transparent, Highly Conductive Poly(3,4-ethylenedioxythiophene) Figure 6. The variation of solution concentration (in methoxy ethanol) at, 15 % (squares), 30 % (circles), and 45 % (triangles), leads to different values in conductivity (solid symbols) and transparency (open symbols). The transparency follows Beer's Law for all concentrations studied. Furthermore, higher solution concentration leads to higher conductivities presumably due to higher molecular weight chains that allow longer delocalization of the conducting orbitals. Hence, this confirms that the molecular weight is indeed the dominant factor in improving the conductivity of these materials. Furthermore, the conductivity most likely follows the classical relationship (low conductivity at very thin films but saturates to a constant value after a finite thickness is reached),[36] and each solution concentration is likely to exhibit a qualitatively similar, but quantitatively different trend. Unfortunately, our experimental conditions simply do not allow us to access the full range of thicknesses to clearly elucidate this for each concentration. 2.1.5. Optimization of Properties Having thus arrived at a clear understanding of the role of the various variables associated with oxidative polymerization in the overall materials properties of PEDOT, we can achieve an optimized combination of properties. For this purpose, we have set the Im/Fe(OTs)3/EDOT ratio as 2:1.75:1 using pentanol as the solvent at a 60 % solution concentration. Results obtained under these conditions show a dramatic improvement in conductivity and transparency (see Fig. 7) reaching 750 S cm±1. 2.2. Further Improvements Utilizing EDOT±CH2OH Our studies on PEDOT, which involve maximizing the chain length with a controlled level of doping, suggest that PEDOTs that can stay in solution longer before deposition as a film should lead to higher molecular weights and thus higher conductivities. As a test of this hypothesis, we have carried out a 620 2004 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim Figure 7. The design and fabrication of highly transparent and conductive films is shown utilizing the principles learned in this study. Conductivity for PEDOT (squares) using 60 % pentanol solution at Im/Fe(OTs)3/ EDOT = 2:1.75:1 resulted in 750 S cm±1 exhibiting 84 % transparency at 300 X/&. Conductivity for P(EDOT±CH2OH) (circles) using 60 % methanol solution at Im/Fe(OTs)3/EDOT±CH2OH = 2.5:2:1 resulted in 900 S cm±1 exhibiting 82 % transparency at 140 X/&. similar set of studies using the EDOT±CH2OH monomers. Results of these studies are discussed and the results are compared with films formed from EDOT monomers. First, the molar concentration of imidazole was increased whilst fixing the Fe(OTs)3/EDOT±CH2OH molar ratio at 2:1 using a 30 % butanol solution. As shown in Figure 1 (open circles), the conductivity reaches a maximum at a ratio of approximately 2.5. These results show that the introduction of an alcoholic side group allows use of significantly higher Im concentrations as compared to unpolymerized samples of PEDOT when the Im molar ratio exceeded two. This is most probably due to the hydrogen bonding of the Im to the ±OH side group on the PEDOT backbone. Thus, the coordination of the Im with Fe(OTs)3 saturates and the excess Im becomes hydrogen bonded to the ±OH side groups in the PEDOT backbone, lowering the conductivity as shown. This implies that the P(EDOT±CH2OH) system should be more susceptible to dedoping reactions as some Im may be hydrogen bonded to the backbone. As shown in Figure 4 (open circles), with Im/ EDOT±CH2OH at a 2.5:1 molar ratio and a 30 % butanol solution concentration, an increase in the Fe(OTs)3 molar concentration leads to a maximum in the conductivity, whereas PEDOT conductivities exhibited a linear decrease under these conditions. This is consistent with the argument of Im becoming hydrogen bonded to the P(EDOT±CH2OH), which causes dedoping, but with increasing Fe(OTs)3 concentration, the system eventually overdopes again. The effect of the ±OH side group poses another interesting variable with regards to the alcoholic solvents employedÐthe possibility of solvent hydrogen bonding with the P(EDOT± CH2OH). The solvent was varied whilst fixing the Fe(OTs)3/ Im/EDOT±CH2OH molar ratios at 2:2.5:1 at 30 % solution http://www.afm-journal.de Adv. Funct. Mater. 2004, 14, No. 6, June concentration. Interestingly, the conductivity decreases with increasing chain length of the solvent (higher boiling point solvents) while the transparency increases (see Fig. 5, open circles). Presumably the longer alcoholic chains are also hydrogen bonded to the ±OH side groups, frustrating packing during polymerization. Although the solvent eventually evaporates, the chains are still in a frustrated packing scheme. This prevents efficient overlap between the p-orbitals on neighboring chains, reducing the effective mean conjugation length as the solvent chains become longer and longer. Lastly, to maximize the conductivity, we utilized methanol as the solvent of choice and systematically increased the solution concentration. In agreement with previous results, the conductivity increases with higher solution concentrations reaching nearly 900 S cm±1 at 60 % solution concentration (see Fig. 7, open circles). We believe that the ±OH functionality confers a higher solubility on higher molecular weight chains in the alcoholic solvent over the PEDOT before forming a film due to the increased favorable enthalpic interactions. To illustrate one additional benefit of P(EDOT±CH2OH), extrapolating the lines in Figure 8 shows that P(EDOT± CH2OH) exhibits higher transparencies than the PEDOT films at a fixed thickness. It appears that the OH side groups pro- of PEDOT and P(EDOT±CH2OH). We have shown that transparency clearly follows Beer's Law and is also partially dependent on doping levels. Furthermore, doping levels control the degree of conductivity that can be achieved, but more importantly, the key to achieving higher conductivities is to allow the polymer chains to reach the highest possible degree of polymerization. We demonstrate the highest conductivities thus far reported for PEDOT by careful control of polymerization conditions (750 S cm±1). Furthermore, we demonstrate an even higher conductivity and transparency by the use of EDOT± CH2OH as the monomer. Unprecedented conductivities of 900 S cm±1 are demonstrated, with the added benefit of higher transparencies as compared to the PEDOT at the same thickness. These studies should provide an invaluable tool for scientists and engineers to tailor a desirable combination of surface resistance and transparency in numerous conducting polymers that can be oxidatively polymerized. For example, we have begun applying this design principle to 2-(2-hydroxyethyl)thiophenes and have observed a very similar trend (surface resistance decreases with increasing concentrations of weak base). Overall, our study demonstrates the potential for improving the conductivity using the design principles outlined in this work on a wide-ranging set of conducting polymer by simply understanding and controlling the polymerization conditions. FULL PAPER Y.-H. Ha et al./Towards a Transparent, Highly Conductive Poly(3,4-ethylenedioxythiophene) 4. Experimental Figure 8. Transparency as a function of thickness for PEDOT (filled symbols) and P(EDOT±CH2OH) (open symbols). Note that extrapolation of the approximate linear functions shows that P(EDOT±CH2OH) is more transparent at a constant thickness than the PEDOT. mote either a lower e (molecular absorption) or c (concentration of the absorbing species), as follows from Beer's Law. Nevertheless, P(EDOT±CH2OH) shows a dramatic improvement in the conductivity and the transparency as compared to PEDOT. 3. Summary and Conclusions We have explored a vast parameter space to understand the role of numerous variables in the overall materials properties Adv. Funct. Mater. 2004, 14, No. 6, June Unless specified, all reagents and solvents were purchased from Aldrich Chemical (Milwaukee, WI) and used as supplied. The EDOT monomer (Baytron M, Bayer) was distilled resulting in a clear colorless liquid. Failure to purify the monomer leads to inferior materials properties. The alcoholic precursor, 2,3-dihydrothieno[3,4-b][1,4]dioxin-2-yl methanol (EDOT±CH2OH), was synthesized according to Stephan et al. [37]. It should be noted that this procedure leads to a mixture of approximately 90 % six-membered (EDOT±CH2OH) and 10 % seven-membered ring isomers (ProDOT), as verified through gas chromatography. This mixture will be referred to as EDOT±CH2OH for the remainder of the text for simplicity. The chemical structures are shown in Scheme 1. Thin films of PEDOT and P(EDOT±CH2OH) (the P denotes polymerized form) were prepared on glass substrates (25 mm 25 mm) by the following procedure. Fe(OTs)3 and Im were dissolved in appropriate solvents (in separate flasks) by heating at 100 C and stirring for 1±2 min. The distilled monomer was then added to the weak base solution and subsequently added to the Fe(OTs)3 solution. The mixture color ranges from clear yellowish to brown depending on the amount of Fe(OTs)3 present. The mixture was then spin-coated onto glass substrates and polymerization was carried out in an oven at 110 C for 2 min under atmospheric conditions, at which point the films turn sky blue. The resulting films were thoroughly washed with methanol and dried with a nitrogen gun. Surface resistances were measured on a four-point-probe bench (Signatone SYS-301), calibrated against indium tin oxide (ITO) on plastic reference samples. The thickness of the sample was measured by scanning force microscopy (SPM) (conditions described below) after making a cut on the film surface with a razor blade to expose the glass surface. The average of at least five measured values at different locations of the sample film was utilized for both the surface resistance and thickness values. On average, the error was approximately 10 % from the measured values. Conductivity values were obtained by the following relationship [38]: r = 1/(SR t) http://www.afm-journal.de (2) 2004 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim 621 FULL PAPER Y.-H. Ha et al./Towards a Transparent, Highly Conductive Poly(3,4-ethylenedioxythiophene) where SR is the surface resistance [X/&] and t is the thickness of the film [cm]. The transparency of the films was determined using the absorption spectra obtained using the Cary 4G UV-VIS spectrometer and integrating the curve from 400±700 nm. Transparency through the glass substrate is used as the reference. Spectroscopic studies of the effects of Im addition on the absorption spectra of Fe(OTs)3 were also performed on the Cary 4G UV-VIS. Spectra of 1 M Fe(OTs)3 in n-butanol (1 mL) in a quartz cuvette was initially taken. Spectra were obtained after each sequential addition of a 2 M Im solution in n-butanol (50 lL each addition) up to a molar ratio of 0.8:1 Im/Fe(OTs)3. Electrochemical studies were carried out utilizing a BAS CV-50W Voltametric Analyzer (Bioanalytical Systems, West Lafayette, IN) using a standard three-electrode configuration. The working electrode was a freshly polished platinum disk (0.03 cm2 active area), the counter electrode was a platinum wire, and the reference electrode was a Ag/ AgCl miniaturized reference electrode (MRE) fabricated according to literature procedures [39]. Prior to measurement, the working electrode was polished with alumina, sonicated in deionized water, and rinsed with n-butanol, and the reference electrode was conditioned in the electrolyte (0.1 LiClO4 in n-butanol) for 10 min. Scans were carried out from 1.0 V to 0 and back to 1.0 V (relative to MRE) at a scan rate of 10 mV s±1. The 22.03 mg of Fe(OTs)3 (33.03 lmol) was dissolved in 5 mL of the electrolyte. A cyclic voltammogram (CV) was taken of the initial solution and then 50±100 lL aliquots of a 0.15 M solution of Im were added and subsequent CVs obtained. The surface morphology of the films was obtained with scanning probe microscopy (SPM) using a Digital Instruments Dimensions 3100. Silicon cantilevers oscillating at a resonant frequency of approximately 300 kHz were used in the tapping mode (DA/A » 40±70 %, where A is the free-cantilever amplitude and DA is the amplitude used for the feedback of the piezo). All images are viewed under height-contrast mode showing the surface roughness of the samples. Selected-area diffraction studies were performed on Phillips CM30 TEM operating at 300 keV. The samples were spun cast onto glass substrates as discussed previously and placed in a petri dish. Water was filled to form a meniscus with the edge of the glass substrate and dilute HF was dropped into the water. The HF etches the glass at the sample/ substrate interface and the film floats on the water surface after a few hours. Samples were collected using a 200 mesh copper grid. Received: September 26, 2003 Final version: November 14, 2003 ± [1] [2] [3] [4] [5] C. K. Chiang, C. R. Fincher, Jr., Y. W. Park, A. J. Heeger, H. Shirakawa, B. J. Louis, S. C. Gau, A. G. MacDiarmid, Phys. Rev. Lett. 1977, 39, 1098. A. J. Heeger, Angew. Chem. Int. Ed. 2001, 40, 2591. A. G. MacDiarmid, Angew. Chem. Int. Ed. 2001, 40, 2581. D. M. Welsh, A. Kumar, E. W. Meijer, J. R. Reynolds, Adv. Mater. 1999, 11, 1379. A. Laforgue, P. Simon, J. F. Fauvarque, M. Mastragostino, F. Soavi, J. F. Sarrau, P. Lailler, M. Conte, E. Rossi, S. Saguatti, J. Electrochem. Soc. 2003, 150, A645. [6] D. M. de Leeuw, P. A. Kraakman, P. E. G. Bongaerts, C. M. J. Mutsaers, D. B. M. Klaassen, Synth. Met. 1994, 66, 263. [7] X. Gong, D. Moses, A. J. Heeger, S. Liu, A. K. Y. Jen, Appl. Phys. Lett. 2003, 83, 183. [8] F. Huang, A. G. MacDiarmid, B. R. Hsieh, Appl. Phys. Lett. 1997, 71, 2415. [9] M. D. McGehee, A. J. Heeger, Adv. Mater. 2000, 12, 1655. [10] W. H. Kim, A. J. Makinen, N. Nikolov, R. Shashidhar, H. Kim, Z. H. Kafafi, Appl. Phys. Lett. 2002, 80, 3844. [11] J. Gao, G. Yu, A. J. Heeger, Adv. Mater. 1998, 10, 692. [12] M. Granstrom, K. Petritsch, A. C. Arias, A. Lux, M. R. Andersson, R. H. Friend, Nature 1998, 395, 257. [13] D. Setiadi, Z. He, J. Hajto, T. D. Binnie, Infrared Phys. Technol. 1999, 40, 267. [14] B. L. Groenendaal, F. Jonas, D. Freitag, H. Pielartzik, J. R. Reynolds, Adv. Mater. 2000, 12, 481. [15] H. W. Heuer, R. Wehrmann, S. Kirchmeyer, Adv. Funct. Mater. 2002, 12, 89. [16] S. Holdcroft, Adv. Mater. 2001, 13, 1753. [17] S. P. Armes, Synth. Met. 1987, 20, 365. [18] S. P. Armes, J. F. Miller, Synth. Met. 1988, 22, 385. [19] J. Roncali, Chem. Rev. 1997, 97, 173. [20] N. C. Billingham, P. D. Calvert, Adv. Polym. Sci. 1989, 90, 1. [21] R. Menon, C. O. Yoon, D. Moses, A. J. Heeger, in Handbook of Conducting Polymers, Marcel Dekker, New York 1998, p. 27. [22] M. Leclerc, Adv. Mater. 1999, 11, 1491. [23] G. A. Sotzing, J. R. Reynolds, P. J. Steel, Adv. Mater. 1997, 9, 795. [24] L. Groenendaal, G. Zotti, F. Jonas, Synth. Met. 2001, 118, 105. [25] A. Kumar, J. R. Reynolds, Macromolecules 1996, 29, 7629. [26] I. Schwendeman, C. L. Gaupp, J. M. Hancock, L. Groenendaal, J. R. Reynolds, Adv. Funct. Mater. 2003, 13, 541. [27] A. Aleshin, R. Kiebooms, R. Menon, F. Wudl, A. J. Heeger, Phys. Rev. B: Condens. Matter Mater. Phys. 1997, 56, 3659. [28] A. Aleshin, R. Kiebooms, R. Menon, A. J. Heeger, Synth. Met. 1997, 90, 61. [29] A. Lima, P. Schottland, S. Sadki, C. Chevrot, Synth. Met. 1998, 93, 33. [30] M. C. Morvant, J. R. Reynolds, Synth. Met. 1998, 92, 57. [31] N. Sakmeche, S. Aeiyach, J. J. Aaron, M. Jouini, J. C. Lacroix, P. C. Lacaze, Langmuir 1999, 15, 2566. [32] Y. Lee, S. Park, Y. Son, Mol. Cryst. Liq. Cryst. Sci. Technol., Sect. A 1999, 327, 237. [33] R. Corradi, S. P. Armes, Synth. Met. 1997, 84, 453. [34] D. Hohnholz, A. G. MacDiarmid, D. M. Sarno, W. E. Jones, Chem. Commun. 2001, 2444. [35] T. Johansson, L. A. A. Pettersson, O. Inganas, Synth. Met. 2002, 129, 269. [36] X. G. Zhang, W. H. Butler, Phys. Rev. B: Condens. Matter Mater. Phys. 1995, 51, 10 085. [37] O. Stephan, P. Schottland, P. Y. Le Gall, C. Chevrot, C. Mariet, M. Carrier, J. Electroanal. Chem. 1998, 443, 217. [38] H. H. Wieder, in Laboratory Notes on Electrical and Galvanomagnetic Measurements, Elsevier, New York 1979, p. 1. [39] M. Ciobanu, J. R. Wilburn, N. L. Buss, P. Ditavong, D. A. Lowy, Electroanalysis 2002, 13, 989. ______________________ 622 2004 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim http://www.afm-journal.de Adv. Funct. Mater. 2004, 14, No. 6, June