Application Characteristics of an Experimental RB-IGBT

Application Characteristics of an Experimental RB-IGBT

(Reverse Blocking IGBT) Module

E. R. Motto*, J. F. Donlon*, M. Tabata**, H. Takahashi**, Y. Yu**, G. Majumdar**

* Powerex Incorporated, Youngwood, Pennsylvania, USA

** Mitsubishi Electric Power Semiconductor Device Works, Fukuoka, Japan

Abstract This paper describes the characteristics of a new

1200V, 100A reverse blocking IGBT chip. It will be shown that this new chip exhibits symmetrical off-state blocking voltage and low losses making it a promising candidate for power conversion topologies such as matrix converters, current source inverters, and AC switches. A prototype module configured for the matrix

From the power device standpoint, possible silicon based post-IGBT solutions seem to be as important as those which can be realized by the potential use of new semiconductor materials, such as the silicon carbide. The RC-IGBT

(Reverse Conducting IGBT) and the RB-IGBT (Reverse converter application using the new RB-IGBT will also be presented.

I.

I NTRODUCTION

Advances in power semiconductor technology have always played a significant role in the development of new power conversion equipment and applications. One of the most

Blocking IGBT) are two silicon based alternatives to conventional IGBTs that are currently under investigation.

This paper focuses on the characteristics and applications of a newly developed RB-IGBT.

100 important trends in power electronic equipment designs is the continual elevation of power density. The remarkable increase in power density over the last two decades is illustrated in figure 1. This trend was enabled primarily by

10

Gen-purpose Inverter

( DIPIPM )

(

M Converter

RBIGBT)

• Efforts toward

SiC Application

•

•

Integration

Technology

New Packaging significant improvements in MOS gated device technologies which lead to successive generations of IGBTs each with improved losses compared to its predecessor. Additional improvements were made possible by increasing the level of integration to produce IPMs (Intelligent Power Modules). If this trend is to be sustained going forward new semiconductor devices will be required.

1

0.1

Gen-purpose Inverter

( IPM )

Gen-purpose Inverter

( Bipolar )

HEV Inverter

( EV IPM )

Note:

IPM: Intelligent Power Module

RC IGBT: Reverse Conducting type IGBT

M Converter: Matrix Converter

DIP IPM: Dual In line Package IPM

EV IPM: IPM for EV and/or HEV applications

RB IGBT: Reverse Blocking type IGBT

HEV Inverter: Inverter systems for hybrid vehicles

Looking to the future, it appears that introduction of new power conversion methods such as matrix converters and/or highly integrated low loss device concepts will be required to maintain an increase in power density following the historical

0.01

1980 1990 2000

Year

2010

Figure 1: Power Density Trend

2020 trend.

Figure 2: Voltage Source Topology

0-7803-8487-3/04/$20.00 (C) 2004 IEEE

Figure 3: Matrix Converter Topology

Figure 4: IGBT based AC switching

=

RB IGBT

Figure 5: AC Switching RB-IGBT

II.

T ARGET A PPLICATIONS

A growing number of industrial power conversion applications require bidirectional transfer of power between the AC mains and load. Examples include rolling mills, conveyor belts, and elevators. In these applications significant energy savings can be achieved by returning otherwise wasted energy to the AC mains. Another important application that often requires bidirectional power flow is processing energy from alternative sources such as wind, photo voltaic, and fuel cells.

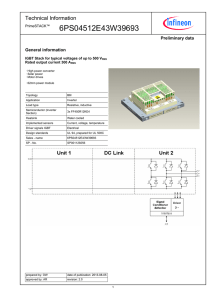

To date most bidirectional four quadrant power conversion system are constructed using a voltage source topology. The voltage source power converter shown in figure 2 consists of two conventional three phase bridges with six IGBT/free wheeling diode pairs in each. This topology requires a large

DC link capacitor between the input and output bridges.

These DC link capacitors often have a significant role in determining the final size and lifespan of power conversion equipment. In addition, electrolytic capacitors must be kept reasonably cool to avoid electrolyte evaporation and maintain long life. This cooling requirement places further limits on the power density that can be achieved.

The matrix converter topology as shown in figure 3 has been proposed as an alternative to the conventional voltage source topology because it does not require large DC link capacitors. One fundamental problem with the matrix converter topology is that it requires nine bidirectional switching elements. Conventional IGBT devices have a limited reverse blocking capability of less than about 20V.

This is not a problem in the voltage source topology because the IGBT is used with an anti-parallel connected freewheeling diode. If a conventional IGBT is to be used in the matrix converter topology it is necessary to use a series connected diode to provide reverse blocking capability. The bidirectional switching element can then be constructed using two anti-parallel connected IGBTs each with a series connected diode as shown in figure 4. This configuration is undesirable because it has increased losses due to the combined on-state voltage of the IGBT and series connected diode. In addition, the large number of discrete chips required leads to a complex and expensive assembly that often negates the perceived advantages of the matrix converter topology.

II.

T HE RB-IGBT

The RB-IGBT (Reverse Blocking IGBT) has a symmetrical blocking voltage characteristic. This means that it can block both forward and reverse voltage in its off state.

As a result the bidirectional switching element can be drastically simplified because the need for series connected diodes is eliminated. Figure 5 shows the resulting circuit

0-7803-8487-3/04/$20.00 (C) 2004 IEEE

1 µ m design rule

Planar Gate IGBT

FFR: Floating Field Ring

Channel Stopper

200 µ m

Thin and lightly doped backside p collector .

NPT structure is necessary for RB IGBT.

Figure 6: RB-IGBT Structure

Deep Diffusion

Isolation

Figure 9: On State Voltage Characteristic of RB-IGBT

4 th IGBT+Diode

Table 1: Loss Comparison

Figure 7: 100A, 1200V RB-IGBT Chip consisting of two discrete silicon elements rather than four.

Elimination of the series diode also helps to reduce losses by decreasing the on-state voltage drop across the switching element. This paper reports on the characteristics of an experimental 100A, 1200V RB-IGBT chip.

III.

S TRUCTURE OF T HE RB-IGBT

The basic structure of the RB-IGBT is shown in figure 6.

The RB-IGBT is similar to a conventional IGBT except that it has a deep diffusion collector wall surrounding the chip active area. This collector isolation allows the IGBT to block reverse voltage. The isolation is produced using a special process designed to maintain a high breakdown voltage and stable leakage current characteristics at elevated temperatures while minimizing processing time. The experimental chip is fabricated using a thin wafer NPT structure. The thin n- layer yields low switching and recovery losses. For simplicity a sub-µm fourth generation planar gate surface structure was selected. This process provides the best trade-off between processing steps and performance. A photograph of a 100A,

1200V RB-IGBT chip fabricated using this process is shown in figure 7.

IV.

C HARACTERISTICS OF T HE RB-IGBT

The RB-IGBT has a symmetrical blocking voltage characteristic as shown in figure 8. The experimental device exhibits low and stable leakage current at elevated temperature in both directions. Figure 9 shows the on-state voltage as a function of collector current. The on-state voltage of just over 3V is about 0.75V lower than a forth generation IGBT with a series connected diode. This

Figure 8: RB-IGBT Blocking Voltage

0-7803-8487-3/04/$20.00 (C) 2004 IEEE

1200V DI RB

4 th

IGBT performances

1200V RB-IGBT

Versus

Gen. IGBT + Diode

-

3rd Gen.

IGBT+Diode

75A/cm 2

75A/cm 2

:RB IGBT

RB-IGBT

87A/cm 2

2

4th Gen.

IGBT+Diode

140A/cm 2

Figure 12: Matrix Converter Module

Internal Layout

Figure 10: E off

versus On-state voltage drop trade-off confirms that the objective of reduced conduction losses has been achieved. Table 1 shows a summary of the switching, recovery and on-state loss characteristics of the experimental device compared to a series combination of a fourth generation IGBT and free-wheeling diode. The low recovery and turn-off losses indicate that the RB-IGBT is suitable for use at relatively high modulation frequencies compared to the conventional fourth generation IGBT. Figure 10 shows the

Eoff versus on state voltage trade-off for the RB-IGBT compared to a fourth generation IGBT with a series connected diode. From this result it is clear that the new RB-

IGBT will provide reduced losses for matrix converter applications.

IV.

M ATRIX C ONVERTER M ODULE

The experimental RB-IGBT chips were assembled into a

Figure 13: Matrix Converter Module special module package designed for Matrix converter applications. Figure 11 shows a connection diagram for the experimental module. The RB-IGBT chip allows this circuit to be realized in a compact 152mm x 109mm package. This module is suitable for a matrix converter with a nominal output power of approximately 22KW at 460VAC. A photograph of the internal layout is shown in figure 12. In this photo you can see the eighteen RB-IGBT chips forming a complete Matrix converter power stage. Figure 13 shows the complete module. Locking connectors are provided for gate drive connections to allow simplified inverter assembly.

U V W

C N 4-4 C N 5-4 C N 6-4

C N 4-1

C N 1-3 C N 1-2 C N 1-1 C N 2-3 C N 2-2 C N 2-1 C N 3-3 C N 3-2

C N 5-1

C N 1-4

R

C N 6-1 C N 4-2 C N 5-2 C N 6-2 C N 4-3 C N 5-3

C N 2-4

S

Figure 11: Prototype Matrix Converter Module

C N 3-4

T

C N 6-3

C N 3-1

0-7803-8487-3/04/$20.00 (C) 2004 IEEE

V.

C ONCLUSION

This paper has presented the design and characteristics of a new 1200V, 100A RB-IGBT chip. The chip has been assembled into a new module package containing all power devices required for implementing a matrix converter.

R EFERENCES

[1] H. Takahashi, et al. “Carrier Stored Trench-Gate Bipolar

Transistor (CSTBT) - A Novel Power Device for High

Voltage Application” The 8th International Symposium on

Power Semiconductor Devices and ICs 1996

[2] E. Motto, et al. “ Characteristics of a 1200V PT IGBT

With Trench Gate and Local Life Time Control ”, IEEE

Industrial Applications Society 1998

[3] H. Iwamoto, et al. “ A New Punch Through IGBT Having

A New N-Buffer Layer” IEEE Industrial Applications Society

1999

[4] H. Nakamura, et al. “ Wide cell pitch 1200V NPT CSTBTs

With Short Circuit Ruggedness ” International Symposium on

Power Semiconductor Devices and ICs 2001

[5] Eric R. Motto, et al. “New Process Technologies Improve

IGBT Module Efficiency” IEEE Industrial Applications

Society Conference October 1995

[6] Eric R. Motto, “A New Low Inductance IGBT Module

Package” PCIM Conference September 1996

0-7803-8487-3/04/$20.00 (C) 2004 IEEE