The ITER Magnets: Design and Construction Status

advertisement

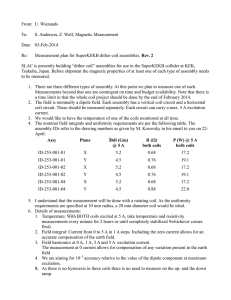

IEEE/CSC & ESAS EUROPEAN SUPERCONDUCTIVITY NEWS FORUM, No. 19, January 2012 Submitted to ESNF Nov. 16, 2011; accepted Nov. 30, 2012. Reference No. ST286, Category 6 The published version of this manuscript appeared in IEEE Trans. Appl. Supercond. 22, (4200809) (2012) 1 2019808 The ITER Magnets: Design and Construction Status N. Mitchell, A. Devred, P. Libeyre, B. Lim, F. Savary and the ITER Magnet Division, ITER Organization, Route de Vinon, 13115 St. Paul lez Durance, France Abstract— The ITER magnet procurement is now well underway. The magnet systems consist of 4 superconducting coil sets (toroidal field (TF), poloidal field (PF), central solenoid (CS) and correction coils (CC)) which use both NbTi and Nb3Sn-based conductors. The magnets sit at the core of the ITER machine and are tightly integrated with each other and the main vacuum vessel. The total weight of the system is about 10000 t, of which about 500 t are Nb3Sn strands and 250 t, NbTi. The reaction of the magnetic forces is a delicate balance that requires tight control of tolerances and the use of high-strength, fatigueresistance steel forgings. Integration and support of the coils and their supplies, while maintaining the necessary tolerances and clearance gaps, have been completed in steps, the last being the inclusion of the feeder systems. Twenty-one procurement agreements have now been signed with 6 of the ITER Domestic Agencies for all of the magnets together with the supporting feeder subsystems. All of them except one (for the CS coils) are so-called Build to Print agreements where the IO provides the detailed design including full three-dimensional CAD models. The production of the first components is underway (about 175 t of Nb3Sn strand was finished by July 2011) and manufacturing prototypes of TF coil components are being completed. The paper will present a design overview and the manufacturing status. Index Terms—Magnetic magnets, Fusion reactors confinement, Superconducting I. MAGNET REQUIREMENTS T A. Operational Performance HE function of the ITER magnets, Fig 1, i s to form, control and drive the tokamak plasma [1]. For this purpose, the Toroidal Field (TF) coils will provide a s teady field of 5.30T at a radius of 6.20m. The Central Solenoid (CS) and Poloidal Field (PF) coils will be capable of 30000 inductively driven 15MA plasma pulses with a burn duratio n of about 400s. Hybrid and non-inductive plasmas will also be within the coil capabilities (where the plasma current duration is extended by non-inductive current drive methods), with burn durations up to 12000s. An extensive database of plasma scenarios (coil currents and plasma details) has been simulated and is used to confirm the coil capabilities [2]. The CS and PF coils are desi gned also for feedback control of plasma Manuscript received 12 September 2011. disturbances at frequencies up to the 100Hz range. In terms of the number of operational c ycles for other conditions, the coil system is designed for 100 cooldown and warm-up cycles, 1,000 TF charging cycles, 50 TF fast discharges and 10 TF quenches. A fast discharge of the CS or PF coils is les s onerous th an the ref erence inductive plasma cycle and so no extra limits are imposed. Achieving reliable quench detection for the coi ls [3] is critical for successful operation, not only because o f the obvious need to protect against coil damage but because false positives will i nterrupt machine availability, especially of the TF coils. The magnet quench detection system will be able t o distinguish between superconductor quench and the electromagnetic perturbations caused by a plas ma disruption with a reliability of >90% for the CS, Correction Coils (CC) and PF co ils and >99.9% for the TF coils. The quench detection system of the coils (particularly the TF) must be designed to allow possible tuning during commissioning as experience with plasma behaviour is obt ained. The magnets need not be ready f or further operation (i.e. completely recooled) until 96hrs after a f ast discharge of the TF system. In the event of a fast discharge of only CS , PF or CC, the magnets will be re-cooled ready for further operation within 2hrs. In the event of a fast discharge of any or all of the magnets, the Helium expelled from the system will be collected and stored. There is negligible expulsion from CS, PF or CC dur ing a fast discharge but, due to eddy current heating of the radial plates, almost all the TF helium is expelled as the temperature rises to about 50-60K. The magnet system cooldown will not occur at an y time faster than 1K/h and the maximum temperature difference between inlet and outl et supplies will be 50 K . It will be demonstrated by analysis that the maximum temperature differences inside the modules and structure do not exceed 50 K. Cooldown from RT to 4K will be achieved within 30 days. B. Tolerances Tolerances are essentially in any real engineering component and affect the ITER coils in three ways. Firstly, the departure from ideal shapes and locations of the c oils generates so called ‘error field’. Approximately, the allowable departure from axisymmetry of either toroidal or poloidal field is about 3x10-4 T [4]. The correction coils are placed and sized so that they can correct the most significant error modes in the poloidal field (up to mode 3 in either poloidal or toroidal 1 of 9 IEEE/CSC & ESAS EUROPEAN SUPERCONDUCTIVITY NEWS FORUM, No. 19, January 2012 2 2019808 directions). Thee two main sources of thee error field are the unnpaired lengthhs of busbars that are req uired to conneect the cooil terminals too the main cryyostat feeders,, though it is second more significannt) arises f rom m coil orrder. The secoond source (m poositioning errrors. Seconddly, the pe nalty for alllowing increased toleraances is generrally that highh strength struuctural a A marrgin of material is lost, replaced by weak filler material. 100% is allowedd in the desiggn between maximum alloowable strresses and thoose calculatedd by stre ss annalysis for thee ideal metric imperfeections. Thirdlly, the geeometry, to alllow for geom cooils and their connections must all fit togeether when installed in the cry ostat, maintain minimum clearrances (generrally a minimum gap oof 50mm is reequired betweeen componentts with ween themselvves and independent flexxing) during operation betw alsso to surroundding componennts such as thee Vacuum Vesssel. Detailed and self-consistennt tolerances have been deveeloped foor all the magnet compoonents, considering these three requirements annd the variouss manufacturinng operations. Costs arre reduced by avoiding tighht tolerances and a balance has to bee maintained between perfo formance and latitude allow wed to suuppliers. Fig. 1. Overview of IT TER and the Magnet System 12-13T (for the TF and CS coils) and NbTi operation up to 6T for the PF. For any set of coils, the heat exchangger bath mayy be reduuced from 4.22K to 3.8K too allow the caapability to c orrect posssible faults or design/annalysis errorrs discoveredd in operation (for example, an underestimatee of the nucclear heatting or a drop in conductor current sharinng temperaturee). E. Safety Because of thee severe effectt of magnet faaults on the ovverall macchine availabiility, and the difficulty off repair, theree are ms built intoo the mulltiple monitorring and prottection system desiign. These incclude inherentt features, dettection/monitooring systtems (that operate continnuously whille the coils are charrged), and testing systemss (that are a pplied periodically wheen plasma pullsing is interruupted or w henn the magnetss are disccharged). Parrticular attenttion is paid to reducing the probbability of potential casscade sequennces, where the exisstence of an innitial fault inccreases the proobability of otthers (forr example, heaat from a shoort degrades a protection baarrier or increases locaal voltages), annd common mode faults where seveeral componnents (due for example to a com mmon mannufacturing errror) have the same initial faault. F From the safetty viewpoint the magnets contain high foorces andd high stored and mobile ennergy. So theree exists theoreetical ms which incclude poteential to im pact neighbouring system tritiuum confinement barriers, either by hea ting or by imp mpact. Studdies have shoown that al l magnet faults are confined with the magnet sysstem with thhe possible exception off an unddetected coil quench (when >10kg of liqquid metal maay be spraayed on to t he vacuum veessel). A sepparate safety class quennch detectionn system has been includedd for the TF coils, locaated outside the cryostatt in the Helium lines, fully indeependent (pressure based) and separatedd from the noormal quennch detection system, to preevent such an initiating evennt. F. Operational Margins and Performannce Verificatioon C. Nuclearr heating The design deecision was made during the ITER Enginneering Deesign Activityy (1993-2001) to limit the nuclear heatingg from ma to 14kW, a level compparable the reference 500MW plasm wiith that of thhe AC losse s, in the ra nge 10-20kW when avveraged over a 1800s plasm ma cycle. Thiss is compatible with the cable-in-connduit conducttor design witth a central cooling chhannel, prevennts the nuclear heating domiinating the cryyoplant sizze and assists in smoothing the cryoplant loads (as AC losses cooncentrate in thhe ramp up annd ramp downn times when thhere is noo nuclear heaating). At thee same time, some optionns are avvailable to operate with exxtra nuclear heeat loads if nuclear heeating predictiions turn out to be inaccuraate. This is achhieved byy adjusting thhe cryoplant operating connditions and/or the plasma pulsing rate (i.e. tradinng of nuclear vs AC losses)). m cooling D. Helium The coils aree cooled withh supercritical Helium at ann inlet mperature of 4.5K (correspponding to a heat exchangeer bath tem at 4.2K). This temperature prrovides good heat capacity of the heelium flow annd matches booth Nb3Sn opeeration in the range The coils have been designedd with supercoonducting marrgins baseed on the resuults from the ITER model coil program inn the A phase of the project, supplemented and updated by tests EDA on short conductoor samples. Thhe margins, inn terms of alloowed degradation of thhe superconduuctor that cann occur beforee the macchine operatioon is comproomised, are coonservative. They for a 30% l oss of superconnductor area while typiically allow fo maiintaining the full operationn temperaturee margin of 0.7K. Sincce superconduuctor degradattion is also geenerally associated withh a more graddual supercondducting transittion (the so-c alled n value), the fulll operation can be maintaained beyond this leveel of degradatiion if the coil cooling is incrreased. Margins also exist to c over uncertainnties in the coil operating condittions, particullarly for nucclear heating and plassma disruptionns. G. Repair Some in-situ repair possibillities are bu illt into the maagnet ws: systtem, as follow Inn situ repair (in all case s hands-on acccess is requuired, posssibly with locaal removal of the thermal shhield): 2 of 9 IEEE/CSC & ESAS EUROPEAN SUPERCONDUCTIVITY NEWS FORUM, No. 19, January 2012 3 2019808 Retightening of the CS precompression structure. A loss of 5% of the initial prec ompression is required to be within the design capability. Above this the situation must be reviewed and operating window restrictions may be imposed until retightening can be scheduled. Retightening of the TF Precompression rings. A loss of 5% of the initial pretension is r equired to be within the design capability. A review is required if operation is continued with a higher loss. Retightening of bolts on TF gravity support plates, CC support plates and PF coil clamps Bridging of a failed PF double pancake Repair of He pipes and He inlets in the CS bore and at TF and PF coil terminals Removal (medium difficulty): Extraction of CS stack (no removal of feeders/coils) Removal and replacement of TF Precompression rings (this requires removal of the CS) Removal of PF1 Replacement of inner poloidal keys (partial removal of CS and PF1/6 coils) Removal (high difficulty): Removal of a TF coil Removal of PF2 To ease re moval of the CS (which may be required fo r replacing the Precompression Rings) the upper connections of the CS to the feeders are aligned to allow the CS s tack to be lifted vertically once the joints are opened, without removal of the feeders. Because of the long timescale and hig h cost of manufacturing replacement coils once manufacturing is complete and tooling is dismantled, one spare CS module and one spare TF coi l are included in the procurement. It is as a result a requirement that all CS modules are interchangeable. Certain large components can only be p laced in the lower cryostat during assembly. Therefore, 3 spare precompression rings and jumpers for the PF coil double pancake bridging are stored below the tokamak assembly in case of need. II. SYSTEM OVERVIEW AND INTEGRATION The overall operational requirements of the magnets define the basic functionality but obviously leave open many design choices, many of which affect also the design of the rest of the machine. The following section gives a brief summary of the final design choices. More details are given in [5]. The magnet system for ITER consists of 18 TF coils, a CS coil stack with 6 coil modules, six PF coils and 18 Correction Coils (CC), Fig 1 and Table 1. The 18 TF coils determine the basic toroidal segmentation of the machine and were chosen to meet the requirements of access ports (both number and size) and the ripple at the plasma edge. Both CS and TF coils operate at high field and use Nb3Sntype superconductor. The PF co ils and CCs use NbTi superconductor. All coils are cooled with supercritical Helium with a co il inlet temperature of 4.5 K. The conductor is a cable-in-conduit conductor with a c ircular multistage cable consisting of about 1000 strands cabled around a small central cooling spiral tube. The cable is contained in a circular jacket for the TF coils or a jacket with an outer square section for the other coils. The op erating currents are 40-45 kA for the CS, 45-55kA for the PF coils and 68 kA for the TF coils. The CCs use a reduced size cond uctor, 16kA, with about 300 strands and without the central cooling channel. The coil electrical insulation system is composed of multiple layers of polyimide film-glass impregnated with epoxy resin (a radiation hard cyanate ester based r esin in the case of the TF coils). Epoxy-glass and f illed epoxy resin is used extensively to fill tolerance gaps. The TF coil case encloses the winding pack and is the main structural component of the magnet system [6]. The TF coil inboard legs are wedged all along their side walls in operation, with friction playing an important role in supporting the outof-plane magnetic forces. In the curved regions above and below the inboard leg, the coils are struc turally linked by means of three upper and t hree lower precompression rings formed from unidirectional bonded glass fibre and by four upper and four lower sets of poloidal shear keys arranged normal to the coil centreline. In the outboard region, the outof-plane support is provid ed by f our sets o f Outer Intercoil Structures (OIS) integrated with the TF coil cases and positioned around the perimeter within the constraints provided by the access ducts to t he vacuum vessel. The OIS form four toroidal rings and act as shear panels in combination with the TF coil cases. Th e TF conductor is co ntained in grooves on each side of flat D shaped steel radial plates. Seven DPs are assembled together to form the winding pack of one TF coil. The CS assembly [7] consists of a vertical stack of six independent winding pack modules, which is su pported from the bottom of the TF coils through its pre-load structure. The pre-load structure consists of a set of toroidally segmented tieplates located at the inner and outer diameters of the coil stack. It provides axial pressure on the stack throug h key blocks . The CS modules use a square section jacket which is self-supporting against the radial and vertical magnetic forces. The six PF coils (PF1 to PF6) [8, 9], are attached to the TF coil cases through flexible plates or sliding supports allowing radial displacements. The square conductor provides the coil structural support. Outside the TF coils, and mounted on t heir cases, are located three independent sets of CC [ 10], each consisting of six coils arranged around the toroidal circumference above, at and below the equ ator. Within each set, pai rs of coils on opposite sides of the machine are connected in series. The coil supplies (helium, current and instrumentation [11]) are grouped into feeder ducts [12, 13] that run from outside the cryostat, initially within cryostat extensions and then inside the main cryostat, largely above and below the coils. The valves, current leads and instru mentation cubicles are placed in galleries just outside the bioshield [14]. The current leads make use of HTS technology [15]. 3 of 9 IEEE/CSC & ESAS EUROPEAN SUPERCONDUCTIVITY NEWS FORUM, No. 19, January 2012 4 2019808 whiich are custom m machined too achieve a tigght fit of the shear keys in those lineers. The assembledd 1/9 machine segments aree transferred too the pit in the tokamaak hall, Fig 2. The vault sttructure of thee TF coill inboard legs is built up cirrcumferentiallly, with correcction ms every 3 pa irs if of the accumulatted assembly error by shim neceessary (althouugh the intentioon is that the coils are machhined mming at asseembly). accuurately enoughh to avoid shim The upper andd lower OIS structures agaiin act as referrence surffaces for the assembly operaation. Once thhe vault structuure is mplete, the rem maining OIS keys are installled. After the OIS com panel structure liinking the ouuter legs is c omplete, the upper andd lower preccompression rings are innstalled and pretenssioned. The ring pretensioning can be adjustedd to mpensate for any settlinng effects. Retensioningg, if com neceessary, can bee performed with the CS in-ssitu. All Correctionns Coils (low wer, side andd upper) are then attached to the TF coil cases. The PF coi l installation starts withh a survey of the support poositions on the TF coil casees. If requuired, approprriate shims arre prepared annd installed beefore the PF coils are atttached to the TF coils. Coil current ceentre alignmennt could be doone on the bassis of the geometry of the winding paack, measuredd at the final sttages of manufacturingg. However, direct measureement of the locus of the current ceentre line is exxpected to bee possible at room mperature with a small AC current in the coil to an accuuracy tem bettter than 1mm. A prototype system is beingg developed [66]. The feeder insstallation (apaart from the CC header rinng) is the next step inn the magneet assembly. Those underr the macchine are ei theer lowered innto position thhrough the borre of the TF coils or brrought in throuugh the side poorts. Finally, the CS is assemblled outside, complete withh its prelload structure and all terminnals and coolinng pipes. It is then low wered into the inner bore of the TF coils and attached too the F coil inboardd legs. suppports at the boottom of the TF ABLE 1 COIL MAIN PARAM METERS TA Paraameters TF Number of coils Number of turns per coil or WP Stored magnetic energy GJ Maximum operatiing current kA Nominal peak fielld T Electrical dischargge time constant**s CS PF 18 6 6 134 549 1155-459 41GJ 7 4 68 45 45 11.8 13.0 6.0 15 11.5 18 Conductor total leength m 82260 36114 633142 Coil total weight (with case and structures) t 298 (1 coil) 954 (all) 2163 (all) S/C strand total weight t 410 104 240 Winding Pack weight t 110 688 1361 Coil Case weight t 188t NA NA 403MN NA NA Vertical force per coil, max MN NA 327 160 In plane bursting force per half coill MN (max for CS and for each PF) 205 220 43,13,30, 19,64,54 Length of the coil centerline m 34.1 10.7 255-75 4570m 6019 60009144067 760/ 415 903/601 3877-879 C Cross section of thhe steel at TF innboard mid planee (jacket + RP, ccase) or in coil secction (CS, PF) m2 0.562 0.86 0.444,0.2 0.322,0.29 0.377,0.82 He mass flow ratee in conductor g/s 8 8 8-14 He mass flow ratee of structures kg//s 2.5 Centring force perr coil WP Conductor lenngth Conductor Unit Length Range m *Note that thiss is the overall theermal equivalent exponential valuee as teemperature depenndent resistors aree used and there iss a detection delaay time III. ASSEMBLY This section is a brief summ mary of the main assembly steps. The lower PF F coils (P5 annd P6) and thhe lower Corrrection Cooils (CCs) are the first cooils to b e placed in positioon, on mporary suppports at the bottom of thee cryostat. Various tem eleements of the support structture are also put in position at this tim me (such as thhe lower precompression riings and the gravity wer correctionn coils suupports). The feeders for thhe side and low (thhe lower header rings) are also positionedd. The TF coils are assembleed in pairs in the assembly hall at the ITER site as part of a 1/9 vacuum vesssel sector com mplete wiith its thermall shield, Fig 2. The tightly toleranced intterface regions betweeen the two coils will h ave been preecision h factory but additional shimming can be machined in the wer OIS acts as the prrovided as re quired. The upper and low reference surfacce and joint too link the coills for this operation. Eaach coil has a thin 'sandwich' of innsulation, conntained beetween two steel sheets, that is fixed to one of thhe coil weedging surfacces (welded orr bonded) durring manufactturing, annd shims can be attached by welds to thhe outer sheet. Slots foor the shear keeys are oversizzed to allow the use of slott liners 4 of 9 Figg. 2. 1/9 VV segm ment and 2 TF coils, with temporaryy supports, insidee the cryostat IEEE/CSC & ESAS EUROPEAN SUPERCONDUCTIVITY NEWS FORUM, No. 19, January 2012 5 2019808 NG IV. MANUFACTURIN In this secttion we givve a brief description of the mponents. Thiss is the manufacturing ooperations for the main com me originally foreseen forr the coils annd for reference schem whhich the desiggn is optimisedd. Individual Domestic Ageencies, responsible forr the procureement, may adjust this in the interests of costt reduction. A. Conducctor The componeents of the coonductor are the supercondducting strrands, copperr wires, an oppen spiral thaat forms the central coooling channeel, steel wraps for AC losss barriers to cable suubstages and for protection of the final cable, and exxtruded seections of the jacket (eitheer circular forr the TF coils or a sqquare outer seection with a circular hole for the CS a nd PF. Thhe manufacturring is illustratted in Fig 3 [116]. The strands and coopper wires aree cabled to a multistage circcular cable, thhe final m jacket sectioons, 1suubstage of whiich has 6 ‘petaals’. The 7-11m 2m mm oversize on the cable, are butt welded d together to form a fuull unit length (this process allows easy weld inspectioon and tessting) before the cable is pulled into it.. The jacket is then coompacted by rolling, onto the cable. Thhe process reequires caareful control of dimensionaal tolerances so that the cabble can fitt the jacket wiith a 1-2mm clearance and a pulling forcce <5t, mental to the jacket wiithout excessiive compactionn that is detrim mechanical prooperties (it haas to wi thstannd the Nb3Snn heat treeatment withoout grain bounddary sensitisattion). Fig. 3. Steps in Conduuctor Manufacturiing Process B. TF Coill Winding Pacck The conductoor is wound innto a mould holding the shhape of the conductor during the reeaction heat treatment [177, 18]. Duuring the mannufacture of the TF Modell Coil, it was found that the conducctor may expperience a peermanent elonngation affter the heat treatment up to 0.05%. During heat treaatment, the conductor is held flat byy clamps but is allowed to move raadially. The innitial winding dimensions must take accoount of this possible chhange in lengtth after heat trreatment so t hat the reacted conducttor can fit in thhe RP groovess. Once the DP is wound but before heat treatmennt, the coonductor jackeet at the i nnerr transition reegion is ope need and the helium inlett formed. Thee conductor teerminations arre also foormed after winding but before heatt treatment of the coonductor. Theyy consist of thhe terminals (2 per WP) annd the DP to DP joints (6 per WP). The conductorrs are then heat treated (about 650°C C for 2000hrs) in a furnace with a conntrolled inert atmosphere. After heatt treatment, thhe top and botttom single paancakes are moved ween verttically up andd down respecctively to cre ate a gap b etw m and allow the removal of the mouldd. The RP is then them inseerted between the two separrated pancakees as shown inn Fig 4. The removal of the mould and the in serttion of the RP P are mplex operatioons requiringg a purpose-ddesigned handdling com toolling and a special set of insertion movements. The alloowable maxim mum strain on the conductor (±0.1%) limitts the pancake separatioon. Fig. 4. Transffer of Conductor DP from Mould to Radial Plate The conductor is then locallly lifted to alloow the applicaation ween of the turn insulation. Thee correct aliignment betw conductor and RP groove hass to be mainttained during this mber of outer glass proccess, using maarks and adjuusting the num wraaps, to preventt a progressivee buildup of misalignment. The widdth of the RP grooves iss adapted to allow a s mooth embbedding of the reacted conductor and accommoodate winnding tolerancees and possiblle permanent elongations of the reaccted conductoor. The clearrance betweeen conductor and grooove is 3mm inn the upper annd lower regioon and 2mm inn the outbboard region. The resultingg gaps will bee filled with glass clotth shims durinng application of the turn inssulation. The RPs are thhick plates maade of austeniitic stainless steel, typee 316LN. Thee manufacturinng process forr the RPs reliees on macchining of pllates (produceed by hot roolling, forgingg, or hippping [17, 18]) to form sub-ssections whichh are assembleed by welding. The butt welding is simplifiedd by maintaiining recttangular butt sections and completing the radial groooves afteer welding, byy local machinning. A final machining off the plattes is possiblee in case that the groove needs to be adjuusted fit the final shaape of the condductor. to fi Each jacketed conductor iss locked in thhe RP groovee by meaans of a coveer plate (CP). The CPs haave holes at 20cm w during the vacuum presssure spaccing to enable resin flow VPI) process. The CPs a re fixed by laser imppregnation (V welding with a continuous seaam of at least 1mm depth inn the outbboard leg and at least 2mm depth in the inn-board. The whole DP assembly, with grounnd and conduuctor insuulation, is thenn vacuum-presssure impregnaated in a moulld. 5 of 9 IEEE/CSC & ESAS EUROPEAN SUPERCONDUCTIVITY NEWS FORUM, No. 19, January 2012 6 2019808 C. TF Struuctures Each leg of the TF Coil Case (TFCC) is formed by a subasssembly of 4 components, with an inner U-section and a cloosure plate subb-assembly [119]. BU BP AU AP Fig. 6. Keyy Interfacing Planees and Surfaces on Sector AU Fig. 5. The 4 Sub-Asseemblies of the TF F Coil Case mblies have numerous inntegral Both U-secttion sub-assem strructural attachhments such as the Intercoill structures, thhe precoompression flaanges, the TF coil support leg, and attachhments foor the CS, PF F, CC, vacuum m vessel t herm mal shield (V VVTS) suupports and maachine assembbly tooling. The casing opperation compprises three maain phases [200]: Inseertion of the WP into the casse; Clossing by weldinng the TFCC elements; Finaal impregnatioon of the TFCC C-WP gaps. The final toolerances acceeptable on inndividual coiils are deetermined by the coil fit during assembbly in the cryyostat, together with the allowablee magnetic fiield errors annd the maintenance off operational clearances. The tolerances on case seections, windinng pack and the casing opeeration are ballanced to give maxim mum manufaccturing latitudde. The indiividual suubassemblies are built upp by a s ucccession of foorging, machining, welding l and maachining steps. s The key to cost reduction in t hiis process is a predictable and localizedd weld distortion so thhat the nu mbber of machinning steps, a nd the mount of overrmetal, are minimized andd eliminated on the am finnal closure weelds. The AU s ub-assembly is the key to maintaininng the tolerances. The flat inner surfface of the AU U sub-assemblly will prrovide precise geometric loccation and unniform force trransfer interface for thhe winding paack. The base line design reequires mized shim over the com mplete the installationn of a custom interface with a precise flatness annd perpendicuularity U sub-assembly are tolerance. The angular facees of the AU deefined with a wedged 20° angle. These faces will defiine the plane for refereence to the currrent centre liine plane of thhe WP duuring insertionn and they theen are used as references for the location of the TF coil in the ITER machinee, Fig 6. The case su b-assemblies are designedd with assem mbly cleaarance gaps too the WP. Thee design clearance will be 7mm P angled facees and W P-AU U) or 10 mm (WP vs BU––AP– (WP BP)). The go al of these c leaarance gaps is to re movee the requuirement for tight tolerancees on all the WP-TFCC maating ment of the WP relative too the surffaces and to allow alignm CC at insertioon. The finall geometric loocation and force TFC trannsfer between the WP and Case will be achieved by fiilling the inter-space wiith a charged epoxy. The WP will be lowered intto the AU elem ment, aligningg the P by means of an overhead bridge crane annd three alignm ment WP guiddes. The a lignnment guides will align t he WP while it is slightly lifted oveer its final possition so its weight is still taken m the crane and the g uidess do not havee to apply a large from forcce, Fig 7 . Pre-machined G110 shims willl be placed onn the AU surface to suppport it. WP mid-plane mid-plane A mid-plane AU mid-plane G = A* = J** B* A B J = = Figg. 7. WP and Case Mid-Planes andd Reference Points t for WP Insertion in AU Sub--Assembly The BU sub-aassembly willl be lifted using tooling and braccing to minim mize distortioon. The sub- assembly willl be wered over thhe WP and thhe interfaces to the AU sublow asseembly broughht into locatioon. The matcching of the weld faces will bee checked annd the geom metric prepparation surfa locaation of the BU reference marks surveyeed with respeect to the AU reference marks and thee WP fiducials. There is a t woo stage weld sequence. Ann initial laser root mm made witth the TF cooil in the verrtical weld of 10–20m (inssertion) orienttation. A finaal structural weld made byy the W) with the TF coil rotated too the Subbmerged Arc Method (SAW horiizontal positioon. This weld is to be made after filled resin imppregnating the WP to TFCC gap is compleetely cured. After welding of the AU-BU U interface it will be necesssary P relative to the TFCC struucture in ordeer to to block the WP 6 of 9 IEEE/CSC & ESAS EUROPEAN SUPERCONDUCTIVITY NEWS FORUM, No. 19, January 2012 7 2019808 remove the WP support jigs and braces; this is necessary to insert the final case sub-assemblies AP and BP. At this stage the CCL fiducial marks of the WP will be transferred to the TFCC prior to closing it with the sub -assemblies AP and BP. When fiducial marking transfer is complete, cover plat es AP and BP will b e installed. The first step will be the laser root welding of the closure plates. After the clos ing of all welds with laser techniques and the W P-TFCC gap filling by vacuum pressure impregnation with a resin/filler [6], the TFC will be rotated to the horizontal position for completion of the case welding by Submerged Arc Weld (SAW). E. PF Coils A simplified flow diagram of the PF co il manufacturing process is shown in Fig. 9. Starting from the conductor spools, two in hand Double Pancakes (DP) are wound, insulated, vacuum-impregnated with resin, then stacked to form coils, and bonded with a further vacuum impregnation step. D. Gravity Supports The TFC assembly rests, via 18 Gravity Supports (GS), on a tokamak pedestal ring s upported by 18 columns off the concrete floor slab of the tokamak hall. The GS consists of a flexible plate assembly (FPA), clamping bars, studs and bolts, as shown in Fig. 8. The FPA is pre-assembled in the factory from 21 flexible plates (with cooling pipes and thermal shields sections attached), separated by 20 short spacer plates at t op and bottom. The FPA components are pressed together at top and bottom between pairs of horizontal pre -stressing bars by tie-rods. The FPA is designed with sufficient pre-compression and friction to prevent both sliding and separation between its components. The FPA of each GS flexes within allowable stresses to accommodate the radial thermal contraction of the TFC assembly. But the GS is r igid versus c yclic out-of-plane bending caused by TFC torsion during plasma operation, and versus vertical and horizontal forces parallel to the flexible plates due to deadweight, asymmetric plasma VDE and earthquakes. The 1 8 GS transmit these loads to the pedestal ring, which is an integral part of the cryostat structure. Fig. 9. Simplified flow diagram of the PF coil winding, impregnation, and assembly Tolerance control is required throughout the manufacturing to ensure that subc omponents interface correctly. The manufacturing scheme has therefore been defined with an allocation of overall tolerances in the coil current centerline position at the different manufacturing stages, and the possibility to allow reductions in position errors during the winding – DP stacking. Assembly errors and manufacturing errors for the PF coil s are defined in Fig. 1. The targ et tolerances for the PF coil winding pack are defined in Table 2. Clamping bars Thermal anchor and radiation shield Fig. 10. PF Coil Tolerances TABLE 2 TARGET TOLERANCES FOR PF COILS IN MM Manufacturing Assembly Pre-stressing bars Fig. 8. Details of a Gravity Support PF1, 6 x ±3 y ±3 z ±3 x ±2 y ±2 z ±1 PF2, 5 ±3 ±3 ±3 ±2 ±2 ±1 Coil Flexible plates ±4 ±4 ±3 ±2 ±2 ±1 PF3, 4 The shaping of the termination is performed after completion of winding. This operation is needed to allow the 7 of 9 IEEE/CSC & ESAS EUROPEAN SUPERCONDUCTIVITY NEWS FORUM, No. 19, January 2012 8 2019808 prroper fitting of the final filllers into the winding pack. To do this, a p ortion of conductor (about 3 m) is opened, thhe turn moved and thee joggling is performed by shaped insulation is rem h close the winding table. moulds, brought The windingg DP is then placed in a mould and vaacuum mpregnated with resin. Durring this p roccess, the connductor im ennds, which caarry the terminnations to be used for the joints beetween doublee pancakes, must be keppt unbonded to the m. This is to provide wiinding pack over a length of typically 5m flexibility wheen the jointss are made. These the required fl coonductor ends are, thereforee, provided with an anti-addhesive wrrap before impregnation. This wrap is removed after im mpregnation. The DP is heated-up to aboout 80 degreess, by passing current through the connductor. At thee same time thhe resin is putt under vaacuum, degasssed and heatedd up to 80 degrrees. Once thee DP is w starts at the lowest hoot it is put undder vacuum. The resin flow pooint of the DP, in sin glee location, annd gets ou t in the diametrically oppposite positioon, at the highhest point of thhe DP. Thhe resin is forcced to face thee bottom surfaace of the DP and to floow through thhe winding to reach to the suurface of it. The DP siddes have no resin passagges. The whoole impregnattion is wly, to allow the resin to wet the insulatiion, to peerformed slow takke advantage of the capilllary effect and to avoid crreating traapped bubbless in the windinng. After the imppregnation is complete, thee DP is put first at mospheric pressure r and thhen brought to an overpreessure. atm Thhis helps to reduce and diffuse eventtual trapped microbuubbles of inertt atmosphere into the resin bath. Then, with the P under pressuure, the Curinng Cycle takess place, for about 24 DP hoours at around 130 degrees. Eight DPs aree assembled toogether to forrm the windingg pack off PF 1,3,4,5 cooil and six andd nine DPs aree assembled toogether foor PF 2 an d 6 winding pack respectivelyy. For handlinng, the P is clamped and lifted at a large number of locationns by a DP suuitable Jig to avoid local turn deformatioon and relaxat ion. A layyer of dry gllass is placedd between thee individual DPs to alllow resin peenetration and bonding during the vaacuum mpregnation off the ground insulation and to absorb toleerance im vaariations in thee gap betweenn the DPs. Following VPI of the winding pack, cooling pipes for heelium inlets annd outlets, andd manifolds aree pre-assembleed and coonnected to thee helium inlets and outlets. An insulationn break is attached on each inlet annd outlet. Alll cooling pipes are wrrapped with inndividual grouund insulation up to the insuulation brreaks. F. CS Coills Conductor winding is shoown in Fig. 11. Each connductor lenngth is receivved on a sp ool and is useed to wind eiither a HP) or a qua dpancake (QP P). The co nducctor is heexapancake (H unnwound from the spool to pass through a straighteninng unit beefore reachingg the windingg table. The conductor is wound wiithout any insulation, which impliess that spacerrs are regularly inserteed between tuurns and panccakes to acco unt for the further insttallation of the insulation. Multiple paancake wiinding with a single leength meanss that windiing is alternatively perfformed inwards r and outwaards in successsive plannes, starting and ending on the outsidee. The windinng is circcular, which means that thee radius of currvature is connstant alonng a turn, withh the exceptioon of the jogggle area wheree the conductor is mooving from one turn to the next. This is achiieved throughh a short straigght section folllowed by a cuurved secttion. Much atttention has too be paid to thhis area sinc e any erroor in th e startting point couuld impact thee geometry off the next turn. The coorrect bending radius of the conductor in each secttion is achieveed using a set of bending rollers located at the entrrance of the winding table. Most of the winding is plaanar, withh the exceptiion of the pancake to paancake transiition, perfformed alternaately at the innner and at the outer radius. Fig. 11. CS module winding The location of the He inleets and outletts is only deffined afteer winding thee HP or QP once the futuure location off the inneer and outer tiie plates is esttimated. The conductor jackket is thenn locally machhined in order to insert the prefabricated cover inclluding the He inlet or outlet. Once the uppper terminal is manufactuured, a cl am mping systtem is installeed around thee hexapancake or quadpanncake andd it is transferreed to the heat treatment oveen to form Nb3Sn. The whole sttack of wounnd conductor is clamped and trannsferred to thee insulation staation. In orderr to allow spacce to insttall the wrappping tool, thhe conductor is progressiively unspprung by remooving the spaccers and lowerring down thee turn to be insulated annd putting it inn its final posittion. A continnuous control of the possition of the innsulated turnss is performedd and inteerturn and inteerpancake glasss cloth layers inserted to filll the spacce. The grounnd insulation is installed around the whole moddule at the insuulation stationn. The impregnattion mould iss installed aroound the coil. He inleets and outlets are plugged to avoid any penetration of resin duriing impregnattion. Resin i s injected insidde the mould from botttom to top so as to avoid bubbble formationn. 18 outer tie-plates and 9 innner tie-plates are manufactuured. Theese tie-plates are either cuut from cold worked and shot peenned laminatedd plates o r machined out of forged pieeces. Theey can be spllit into three parts (two ennds and a ceentral secttion) welded together, sincce the thickneess of the endds is largger than that off the central part. The only machined surffaces are the flat surfacces which trannsmit the loadd to the keybloocks, andd the holes for bolting the tiee-plates to the keyblocks. 8 of 9 IEEE/CSC & ESAS EUROPEAN SUPERCONDUCTIVITY NEWS FORUM, No. 19, January 2012 9 2019808 ACKNOWLLEDGEMENT The invaluablee assistance off members off the ITER maagnet mestic diviision and the contributions of the membeers of the dom wledged. agenncies are grateefully acknow The views and opinnions expressed herein do not neceessarily reflect those of the ITER Organizatioon. RENCES REFER [1] Fig. 12. Installlation of the condductor insulation during CS windinng The stacking is performed in the assembbly hall and reequires the use of a special support abble to withstannd the weight of the S plus temporrary structuress. The supportt must be veryy rigid CS m. The ass the key bloccks must remaain in a planee within 1 mm deeformation shoould be such that the stackking of the moodules remains perpenddicular to the reference plann determined by the keeyblocks. Slotts are providedd in the suppoort to allow vertical t modules with their buusbar extensioons. A movement of the mplate is firstt installed on the stacking support to sim mulate tem the 9 supports located at the bottom of thee TF coils. Thhen the lower keyblockks are installled and bolteed to the st acking suupport. The G10 buffer plates are in stalled after having deetermined the correct thicknnesses of the loower and uppeer ones takking into accoount the real height of eachh module. Theen they arre machined inn order to havve the CS equaatorial plane loocated wiith the correctt offset to the machine equaatorial plan att room mperature. Thhe tolerances for the CS modules are givven in tem Taable 3 (see Figg 10 for notatioon). ARGET TOLEERANCES FOR THE CS COILS MM TABLE 3: TA x y z +/-2 +/-2 +/- 1 x y z Stack assemblyy * +/- 0.5 ( CS3L) lineearly +/- 3 +/- 3 [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] Each CS module Manufacturingg [12] to +/-2 (CS3U)) [13] Installation *** +/-2 +/-2 +/-0 * Change in x and y betw ween adjacentt modules < 2 mm ** extra xx, y identical for all modulees at installatioon [14] The precomppression system is then i nsstalled at the top of the CS assemblly. A set of suupernut bolts is used to appply the multaneously on all the tie plates. prrecompressionn by pulling sim Thhis is achieved by tighteninng progressiveely the bolts so that the tensile load is equal in alll tie-plates. When enough gap is prrovided, shimss are inserted between tie-pllates and keybblocks. Affter insertion of the shims and tighteninng of the ho riizontal sccrews, the bollts are unscreewed to releaase the load on the threads. V. CONCLUSIONS The main reequirements, design and manufacturing routes foor the ITER cooil system have been describbed. Constructtion of way and thhe many tecchnical the componennts is underw chhallenges are being successffully solved. [15] [16] [17] [18] [19] [20] 9 of 9 ITER Project Reequirements, ITER IDM reference 27ZRW8, versioon 4.6, May 2010 ITER Magnet Design Descripption Document Part 1, I TER IDM KM, version 1.8, Sept 2009 reference 2NPLK M. Coatanea, J.L. Duchateau, B. Lacroix et al, “Investigationns on Quench Detectioon for the ITER TF Magnet Systeem”, paper presennted at MT22 and publiished in IEEE Traans Applied Superrconductivity, 20112 J. Knaster et all, “ITER non-axiisymmetric errorr fields induced by its magnet system”, Fusion Engineering and Design, in press Aug 20111 N. Mitchell et al, “Status of thee ITER Magnets””, Fusion Engineeering and Design, vol 84, issues 2-6, p1113-121, June 2009 F. Savary, R. Gallix, J. Knaster et al, “The Toroiidal Field Coils for the ITER Project”, paper presented at MT22 and pubblished in IEEE Trans Applied Supercoonductivity, 2012 P. Libeyre, D. Bessette, M. Je well et al, “Adddressing the Te chhnical Challenges for the Construction of the ITER Ceentral Solenoid”, paper presented at MT22 and p published in IE EEE Trans Appplied Superconductiviity, 2012 F. Simon, C. B oyer et al, “De sign of the ITER PF coils joints”, paper presented at MT22 and p published in IE EEE Trans Appplied Superconductiviity, 2012 B. Lim, F. Sim mon et al, “Devellopment of the IT TER PF C oils”, paper presented at MT22 and p published in IE EEE Trans Appplied Superconductiviity, 2012 A. Foussat, W. Wu, H. Li, “Quaalification phase of key technologiies for ITER Correctioon Coils”, paper presented at MT22 and publishhed in IEEE Trans Appplied Superconducctivity, 2012 F. Rodriguez-Mateos, A. F oussat et al, “Thermo-Mechanical Instrumentation for the ITE R Magnets’ Structurees”, paper presennted at MT22 and publiished in IEEE Traans Applied Superrconductivity, 20112 P. Bauer, Y. Chhen, N. Dolgettaa et al, “Ke y Com mponents of the ITER Magnet Feeders”, paper presentedd at MT22 and puublished in IEEE Trans Applied Supercoonductivity, 2012 C. Gung, Y. Ilinn, N. Dolgetta ett al, “Progress in Design, Analysis, and Manufacturing Studies of the ITER Feeders”, papper presented at MT22 c , 2012 and published inn IEEE Trans Appplied Superconductivity Y. Song, P. Baauer, Y. Bi, “Staatus of R&D for ITER Feeder S ystem Procurement in China”, paper preesented at MT22 and published in IEEE Trans Applied Superconductivity, 2012 A. Ballarino, P. Bauer et al, “Thee ITER Current Leads”, paper pressented at MT22 and puublished in IEEE Trans Applied Supperconductivity, 2012 A. Devred, D. Bessette et al, “S Status of ITER Conductor Producction”, paper presentedd at MT22 an d published in IEEE Trans Appplied Superconductiviity, 2012 N. Koizumi, K. Matsui, T. Hemmi et al, “D Development of ITER Toroidal Field Coil in Japan”, paaper presented at MT22 and publishhed in IEEE Trans Appplied Superconducctivity, 2012 A. Bonito-Olivaa et al, “Status off the F4E Pr ocureement of the EU ITER TF Coils, papeer presented at MT22 and publlished in IEEE Trans Applied Supercoonductivity, 2012 M. Iguchi, Y. Chida, K. Takanoo, “Development of structures for ITER Toroidal Field Coil in Japan”, paaper presented at MT22 and publishhed in IEEE Trans Appplied Superconducctivity, 2012 E. Baynham, R. Gallix, J. Knnaster, N. Mitchhell, F. Savary, “The TER”, Insertion of the WP in the St ructural Casing of thhe TF Coils of IT Transactions onn Applied Superconductivity, vol. 20, issue 3, pp. 389 – 393, 2010