Case Study Hydratight Mechanical Connectors facilitate industry first

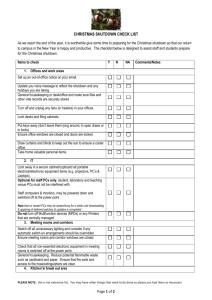

advertisement

Case Study Hydratight Mechanical Connectors facilitate industry first hot-work free platform shutdown The Challenge A Shell/ Esso operated sole pit clipper platform in the southern North Sea required twenty six pipework tie ins. The work had to be completed within a tight 10 day shutdown to minimise loss of production. The Solution Hydratight and AMEC Process and Energy Limited were engaged to undertake an industry first hot-work-free platform shutdown using Hydratight Morgrip™ Mechanical Connectors. Hydratight’s Morgrip™ Connector is a DNV GL- and Lloyd’s Register approved permanent alternative to conventional welded joints. The solution eliminates hot-work for pipework tie-ins and is up to 10 times faster than welding – reducing shutdown times significantly or avoiding the need for shutdowns entirely. Zero leakage is becoming increasingly important, not only for environmental reasons, but also for hazard and explosion analysis. AMEC and Hydraight invited Shell UK Exploration and Production Limited, and DNV, to a Factory Acceptance Test (FAT) to demonstrate the leak free sealing performance of the Morgrip™ Connectors used for the clipper shutdown. The test used a 1% helium/nitrogen mix to a test pressure of the pipe. With the spectrometer set at natural background levels no leakage was detected. All Hydratight Morgrip™ Connectors undergo a Factory Acceptance Test prior to shipment. This combined with the Connector’s external pressure test facility meant there was no need for a time-consuming hydrotest of each system after fitting the Morgrip™ Connector. Above Final pressure testing of the fully installed Morgrip™ Flange Adaptor. Below Fully operational Morgrip™ Coupling. Hydratight and AMEC’s preparatory work ensured the connections were completed in a fraction of the time needed to weld. A total of 16 connectors were used ranging from 2" to 16" all on SCH 120/160 900lb rated process gas pipe work, and the remaining ten connections used standard flanges. All hot-free work was performed successfully in just 10 days. All joints passed nitrogen testing on the first attempt and there was sufficient time left for additional nitrogen testing on the other systems. “With the constrained shutdown resource levels, making the connections by traditional welding methods would have taken an estimated 23 days.” Jim Keeble Project Manager for AMEC Following the sole pit clipper shutdown, AMEC produced a set of guidelines for installing Morgrip™ Connectors. The following page presents a table comparing the actual time of connection for the Mechanical Connector tie-ins, with the equivalent time projections for a welded connection. continued on page 2 continued from page 1 Tie-in Description TP-1 & TP-2 (12") TP-3 & TP-4 (16") TP-5 & TP-6 (3") TP-10 & TP-11 (12") TP-12 & TP-13 (16") TP-14 & TP-15 (12") TP-24 & TP-25 (2") TP-26 & TP-27 (2") Direct man hours Non productive man hours Planned man days Planned shutdown duration including 1 day degas & 2 days repressurise platform Welding Flanges Direct man hours (+) 244.21 314.08 54.98 244.21 314.08 244.21 49.56 49.56 621.1 608.75 360 days Morgrip™'s Direct man hours (*) 58.47 41.98 11.38 58.97 41.98 58.97 10.96 10.96 119.99 117.61 126 days 23 days 10 days (+) Includes all activities, from initial pipe cut through to the flange pressure test ready for system nitrogen test. (*) Includes all activities, from initial pipe cut through to external pressure test ready for system nitrogen test. Jim Keeble, Project Manager for AMEC, said “With the constrained shutdown resource levels, making the connections by traditional welding methods would have taken an estimated 23 days.” Mark Fisher, Senior Offshore Applications Engineer for Hydratight, said: “The ability to undertake maintenance while platforms are in production translates into £millions of increased revenue for operators. This industry first hot-work free platform shutdown proves the flexibility, reliability and huge revenue generating potential of weldless Morgrip™ Mechanical Connectors.” For more information, visit hydratight.com. HT_CS_010_1214_UK