Production and machinery

advertisement

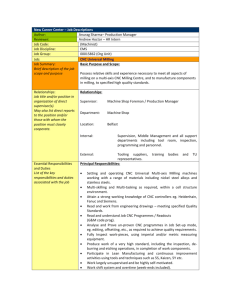

CNC 5-axis universal milling centers Producer Working space of machine (mm) Max. load of table (kg) Ø Turning table (mm) Repeat accuracy (mm) Spindle speed (RPM) Control system DMU100 Machine Deckel Maho 1150 x 710 x 710 800 800 0,01 20 - 12000 Heidenhain iTNC 530 DMU60-60 Deckel Maho 630 x 560 x 560 500 600 0,01 20 - 12000 Heidenhain iTNC 530 DMU60-24 Deckel Maho 630 x 560 x 560 500 600 0,01 20 - 12000 Heidenhain iTNC 530 U740 Hermle 740 x 500 x 500 500 630 0,01 20 - 18000 Heidenhain iTNC 530 C42U Hermle 800 x 800 x 550 850 800 0,01 20 - 15000 Heidenhain iTNC 530 HSCI Producer Working space of machine (mm) Max. load of table (kg) MCFV 1060 ZPS 1016 x 590 x 300 900 MCFV 1060 ZPS 1016 x 590 x 300 900 0,02 MCFV 1060 ZPS 1016 x 590 x 300 900 0,02 MCFV 1060 ZPS 1016 x 590 x 300 900 MCV 750 ZPS 700 x 400 x 300 300 Wikov Sázavan CNC 3-axis universal milling centers Machine Repeat accuracy (mm) Vertical Horizontal 0,02 0,02 Spindle speed (RPM) Control system 40 - 8000 Acramatic A 2100 0,02 40 - 8000 Acramatic A 2100 0,02 40 - 8000 Acramatic A 2100 0,02 0,02 40 - 8000 Acramatic A 2100 0,01 0,01 40 - 8000 Acramatic A 2100 Precise custom machining, production of machinery parts CNC lathe centers Producer Max. dimensions of part (mm) Max. Ø rod mat. Max. spindle load (kg) Repeat accuracy (mm) Spindle speed (RMP) Control system CTX450 Machine DMG Ø machined 400, Ø orbital 650, lenght 600 75 50 0,01 0 - 4000 Siemens 840 D CTX420 DMG Ø machined 324, Ø orbital 680, lenght 450 65 50 0,01 100 - 5000 Siemens 840 D CTX310 DMG Ø machnied 246, Ø orbital 365, lenght 445 50 50 0,01 100 - 6000 Siemens 840 D LU300-MY-2SG-980 OKUMA Ø machnied 340, Ø orbital 530, lenght 980 70 41,5 0,01 20 - 5000 Okuma S50 CNC ZPS Ø machnined 270, Ø orbital 540, lenght 500 50 60 0,025 75 - 4500 Siemens 840 D S50 CNC ZPS Ø machnined 270, Ø orbital 540, lenght 500 50 60 0,025 75 - 4500 Siemens 840 D CNC grinding machine for holes and diameters Machine OGM 390 NL Producer Max. dimenstions of part (mm) Max. spindle load (kg) Repeat accuracy (mm) Control system Roughness Ra OKAMOTO grinding outer and inner diameter and holes Ø machined 300, Ø orbital 320, lenght 900 between centers 150, grippers 40 0,002 "Grind - X Okamoto ver. 1.0-02" 0,1 3D measuring mechine Machnine Producer Max. dimensions of part (mm) Max. load of table (kg) Repeat accuracy (mm) LK Limited 1000 x 710 x 470 820 0,002 Type Max. weight of product (kg) drilling machine 30 XOCM 000/4 bending machine 64 2000 0,5 - 1 t = 4 mm XZM200,2A roll bending mach. 48 2000 0,5 - 1 t = 3 mm; R min = 125 mm eroding, countersinking holes, … LK Integra 10.7.6 Others Machine VR4 (radial) CNC Max. dimensions of part (mm) height 500 Repeat accuracy (mm) Notices 0,1 max. Ø holes 50 mm VO32 eroding 150 300 x 250 x 600 0,1 W75 horizontal bore 900 1150 x 1150 x 900 0,01 Milling machines Type Max. weight of product (kg) Max. lenght of parts (mm) Repeat accuracy (mm) Roughness Ra Spindle speed (RMP) Notices FO-06 Machnine hobbing 30 600 0,05 3,2 95 max. Ø tooth wheel 600 mm; module 0,25 - 6 FO-06 hobbing 30 600 0,05 3,2 95 max. Ø tooth wheel 600 mm; module 0,25 - 6 FO-06 hobbing 30 600 0,05 3,2 95 max. Øtooth wheel 600 mm; module 0,25 - 6 HOR 25 slotting 20 230 0,1 1,6 N/A up to Ø 200 mm; t = 25 - 32 mm FA4AH conventional 400 1050 x 350 x 400 0,2 3,2 1000 FA3AU conventional 300 900 x 240 x 310 0,1 3,2 1400 FGS - 32/4 conventional 200 1000 x 350 x 400 0,1 3,2 35 - 1200 Grinding machines Type Max. weight of product (kg) Max. lenght of parts (mm) Repeat accuracy (mm) Roughness Ra BUA 25 Machine cylindrical + internal 60 1000 0,002 0,8 BDU - 50 internal grinding 8 130 0,01 0,2 vertical 250 2000 x 700 x 400 0,02 1,6 surface grinding 20 600 x 200 x 200 0,01 0,8 BV 70 BPH 20 BPH 20 surface grinding 20 600 x 200 x 200 0,01 0,8 BPH 320 surface grinding 20 1000 x 300 x 320 0,01 0,8 Repeat accuracy (mm) Roughness Ra 0,1 0,8 - 1,6 Notices minimal thickness of material 2 mm Lathe machines Type Max. weight of part (kg) SU50A conventional 200 Max. dimension of part (lenght; diameter) (mm) 1800; Ø 250 SN 40-B conventional 20 450; Ø 250 0,1 0,8 - 1,6 inner through Ø 50 revolver 20 450; Ø 251 0,1 0,8 - 1,7 inner through Ø 50 SUS - 63 conventional 200 2500; Ø 390 0,1 0,8 - 1,6 inner through Ø 80 SN16A conventional 15 300; Ø 120 0,2 1,6 deburr Machine R5 Notices Contacts Wikov Sázavan s.r.o. Okružní 600 285 22 Zruč nad Sázavou Czech Republic T: +420 327 533 302 F: +420 327 533 315 E: sazavan@wikov.com www.wikov.com EN1505 © Wikov Industry a.s. 2015 The Essence of Engineering Wikov Sázavan offers a large spectrum of machining technology, as well as related support processes Components and Assemblies for industrial sectors: Automation Gearboxes CNC 5-axis milling CNC 3-axis milling CNC lathes CNC ginding Vertical grinding Machining Surface grinding Horizontal boring Machine tools Forming machines Jigs for welding and press machines automotive IMM Drilling Plastic industry Gearing milling Construction machines Clasical milling Lathes Vertical slotting Rail vehicles Food industry Glass industry Hard chrome Surface treatment Blacking Painting Timber industry Polygraphic industry One-purpose machines Heat treatment Annealing Tempering CNC 3D measuring Checking/ Technical production Design Technology 2,3% 1,5% 1,1% Jigs Welding Czech Republic Metalworking Others Material cutting 39,1% Germany 56,0% Austria Steel sheet cutting Luxembourg Assembly others Testing