BLDC Ripple Torque Reduction via Modified Sinusoidal PWM

advertisement

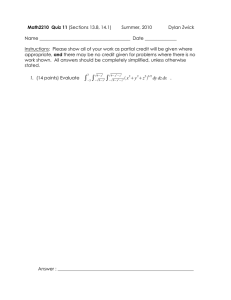

BLDC Ripple Torque Reduction via Modified Sinusoidal PWM Neil Wang www.fairchildsemi.com 1 Why BLDC Motors? Brushless DC (BLDC) Motor Characteristics • • • • • • High Torque Density, Compact Very Low Maintenance Lower EMI than Brush DC Low Rotor Inertia Better Cooling Design - Can Easily be Sealed Safer in Explosive Environments (No Brushes) • Costs More than PMDC – Magnets & Controls • Cost Getting More Competitive - Copper $$$ Rising 2 1 BLDC Torque-Speed Curve Note high torque @ zero speed (very important for many applications!) 3 BLDC Motor Construction Hall-Effect Sensor (x 3) PM Rotor Stator A, B, C Windings 4 2 Typical BLDC Power Electronics Smart Power Module (SPM®) BLDC Motor Windings BLDC motor rs + Ls eb - b n c Ls rs - a - ea + Ls rs + ec MCU, DSC, Controller DSP, or ASIC Hall-Effect Sensors Hall Sensor 5 BLDC Motor Back-EMF Types Bδ θr • Concentrated Windings • Shorter End Windings • Surface Mounted Magnets Bδ θr • Skewed Stator Slots • Distributed Stator Windings • Sinusoidal Field Distribution Note: Can be viewed by rotating shaft externally with scope on motor leads! 6 3 Torque Ripple – Go Away Speed (rpm) Time (50ms / div) Torque (N*m) Time (50ms / div) PWMa (V) Time (50ms / div) ea (V) ia (A) Time (50ms / div) 7 Torque Ripple – Go Away, Please Torque Ripple is Problematic • • • • Audible & Noisy Mechanical Resonance Issues Mechanical Fatigue Precision Speed Regulation Difficult Torque Ripple Reduction Ideas • • • • Use Sinusoidal PWM (SPWM) Acquire Motor With More Poles Implement Modified SPWM Use Permanent Magnet Sync Motor + SPWM • Tip: BLDC with sinusoidal winding pattern 8 4 Trapezoidal / 6-Step Modulation 9 Trapezoidal Modulation System 10 5 Trapezoidal Control Diagram Vdc θ n − θ n −1 11 Trapezoidal Sim Waveforms 1 Speed (rpm) Time (100ms / div) Torque (N*m) Time (100ms / div) PWMa (V) Time (100ms / div) ea (V) ia (A) Time (100ms / div) 12 6 Trapezoidal Sim Waveforms 2 Speed (rpm) Time (50ms / div) Torque (N*m) Time (50ms / div) PWMa (V) Time (50ms / div) ea (V) ia (A) Time (50ms / div) 13 Sinusoidal PWM (SPWM) Modulation 14 7 SPWM Control Diagram Cmd A Sinusoidal Lookup Table Error + - PI Filter PWM Generator Phase A Current Feedback Cmd B + - PI Filter PWM Generator BLDC Motor Phase B Hall Sensors PWM Generator Phase C C=A+B Torque Request Sinusoidal Currents 15 SPWM Sim Waveforms 1 Torque (N*m) Ref, Rotor Freq (Hz) ea (V) ia (A) Time (1s / div) 16 8 SPWM Sim Waveforms 2 Torque (N*m) Ref, Rotor Freq (Hz) ea (V) ia (A) Time (10ms / div) 17 Modified Sinusoidal PWM (Modified SPWM) Modulation 18 9 SPWM vs. Modified SPWM Low loss modified SPWM Normal PWM va' = va − min(va , vb , vc ) ' vb = vb − min(va , vb , vc ) v' = v − min(v , v , v ) a b c c c 19 Modified SPWM Control Diagram Vdc θ n − θ n −1 20 10 Modified SPWM Sim Waveforms 1 Speed (rpm) Torque (N*m) PWMa (V) ea (V) ia (A) Time (100ms / div) 21 Modified SPWM Sim Waveforms 2 Speed (rpm) Torque (N*m) PWMa (V) ea (V) ia (A) Time (50ms / div) 22 11 Modified SPWM Application 23 Modified SPWM Application Photos 24 12 Modified SPWM Schematic FSB50450 IC2 R12 VSP VSP_IN22 1K Hu EW632 1 Vs Q GND 2 3 R3 1.2K 20 19 Hv EW632 1 C14105 C10 105 Vs Q 2 GND 3 R8 1.2K 24 11 R14 10K 2 Q GND 3 R13 1.2K Xin HV U V W X Y Z HW Vref RES CW/CCW LA R15 10K HwEW632 Vs HU Vref C2 103 1 TB6551F 1 VCC 15 Xout 23 LA OS Td 17 FG 16 REV NetC3_1 VCB IC1 4.19M 2 C3 103 Idc P-GND S-GND 14 XTAL1 C8 104 9 8 7 6 5 4 18 R16 R17 R18 R19 R20 R21 100R 100R 100R 100R 100R 100R VM 3 VCC(U) 8 VCC(V) 13 VCC(W) VCC 21 C1 103 Vref Ve C7 102 C11 105 1 4 9 14 5 10 15 COM IN(UH) IN(VH) IN(WH) IN(UL) IN(VL) IN(WL) P U V W 17 18 U CU1 21 V CU2 23 WCU3 CCW VBU 2 VB(U) VBV 7 VB(V) VBW 12 VB(W) 12 10 R2 1.8k 3 U V W C12 102 13 VSU 6 VS(U) VSV 11 VS(V) VSW 16 VS(W) R9 1.2 19 NU 20 NV 22 NW 1K R10 1.2 FSB5045 V_Shunt V_Fg VCC VM VCC Vref C4 22uF/25V C16 1uF/450V C5 103/630V FG D1 R11 R1 4.7K 100R VCC R7 C31 105 S1J REV VM VCC GND VSP FG REV Q2 9013 D2 R33 15R C32 105 VSU D3 S1J VBV C33 105 S1J VCC J02 0R VCC J03 0R VCC J04 0R V_Shunt V_Shunt V_Rev C9 102 J01 0R VCC VCC VBU VCC R4 100R Q1 9013 CON5 6PIN 6 500R VCB 5 4 Z2 C6 3 10V 105 2 1 R31 15R C34 105 VSV V_Shunt V_Rev J05 0R J06 0R J070R R35 15R VBW C35 105 V_Shunt V_Rev SCH Design Tips • • C36 105VSW • Bootstrap Shunt Resistor : 0.5V/(1.5Rated Current) Signal part:R*C = 1.8us 25 Modified SPWM Layout Smart Power Module (SPM®) Advantages • • • • Compact the system (make the PCB board built-in design possible) High density integration Low thermal resistance High reliability PCB Design Tips • • • Bottom Test-Point Isolation Signal GND & Power GND Signal part Bottom Test-Point 26 13 Modified SPWM Waveforms 1 PWMa (100V / div) ia (0.5A / div) Time (400ms / div) 27 Modified SPWM Waveforms 2 PWMa (100V / div) PWMb (100V / div) PWMc (100V / div) ia (0.5A / div) Time (4ms / div) 28 14 Modified SPWM Summary 29 Where From Here Modified SPWM Considerations • BLDC Less Expensive than PMSM • Lower Switching Losses • Decreased Ripple Torque, 50% • When compared to SPWM on BLDC • Maybe Not Ideal Where Application • Requires speed precision • Has very dynamic loads • Runs at high pole frequency See the Fairchild White Paper • “BLDC Ripple Torque Reduction via Modified Sinusoidal PWM” 30 15