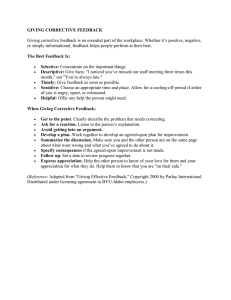

Effective corrective actions to enhance operational

advertisement