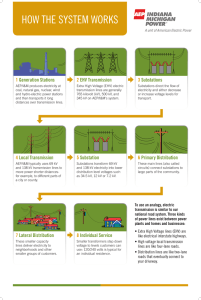

Ground Mounted Substations

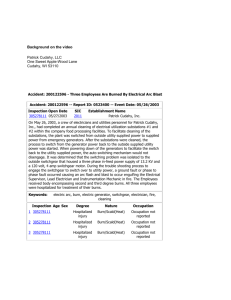

advertisement