PRECAST CONCRETE MANHOLES SECTION

advertisement

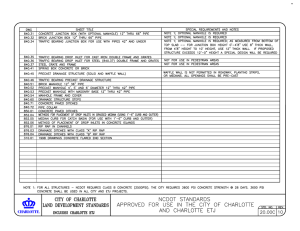

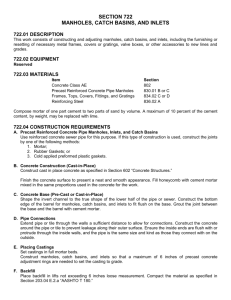

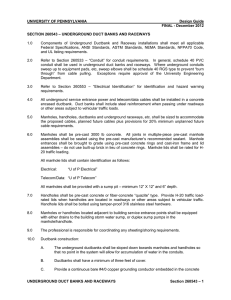

PRECAST CONCRETE MANHOLES SECTION 2738 PRECAST CONCRETE MANHOLES 1.01 SCOPE This section covers the installation of new sanitary sewer manholes. Manholes shall be as specified herein and installed at the locations shown on the Drawings. 1.02 SUBMITTALS The Contractor shall submit for approval by the Engineer the following: 1.03 A. Manufacturer's literature on the materials identified below. recommended installation procedures. Literature shall include B. Certification by the manufacturer that all precast sections furnished under this specification were manufactured, sampled, tested, and inspected in accordance with ASTM C 478 or ASTM C 361. C. Mix design of the concrete used for the manhole base. MATERIALS Precast Sections ASTM C 478. Hanson Concrete Products, Inc., or approved equal. FOR GREATER THAN 72-INCHES ID: ASTM C 361, Class D-25. Flush Bell design, centrifugally spun or wet cast. Ameron, Concrete Pipe & Products or approved equal. Precast Manhole Base ASTM C 478. Hanson Concrete Products, Inc., or approved equal. Sealant Ram-Nek K.T. Snyder Company, Inc., or Equal. Steps ASTM C 478-80 Polypropylene Safety Steps. Frame and Cover D & L Supply A-1024 or Equal. Frame and cover cast by same foundry. Concrete Section 90 Class 2 Concrete. CalTrans Standard Specification. Mortar Section 65-1.06A, CalTrans Standard Specification. 1.03.01 Drop Manholes Drop manholes shall be installed whenever a pipe entering a manhole has an invert elevation 30 inches or more above the top of the outlet pipe in the manhole. 1.04 INSTALLATION CITY OF PALO ALTO: Precast Concrete Manholes Page 1 of 2 PRECAST CONCRETE MANHOLES SECTION 2738 Manhole bases shall be poured in a dry trench, using Class 2 concrete. Concrete will be sampled at the Engineer's discretion. Pre-cast manhole bases may be used upon Engineer’s approval. During the pouring of the manhole base, precautions shall be taken to ensure that the sewer pipes entering and leaving the manhole do not move from the installed alignment and grade. Plugs shall be placed in open pipes to prevent concrete from entering the lines. In case of straight-through lines, the pipe may be laid through the manhole excavation with the base being poured around the pipe. The upper half of the pipe shall then be cut out to form the channel. PVC water stops shall be used on all plastic pipe entering the manhole to prevent groundwater from leaking through the manhole wall. Care shall be taken in setting the bottom manhole section at the appropriate time during the cure of the concrete to ensure penetration (see Standard Drawings) and to allow for two inches of minimum clearance between the bottom of the manhole section and the top of the highest pipe. Manholes shall be plumb. The channels shall be shaped in flowing curves as indicated on the drawings to ensure good hydraulic characteristics for the flow of wastewater. A smooth, clean, hand rubbed finish shall be given to the surfaces of the manhole base and to any joint mortar work. Transitions between different sizes of pipes shall be smooth and regular. Cracks, joints, holes, etc., shall be sealed with non-shrink grout or sealing compounds to ensure watertight manholes. No more than twelve (12) vertical inches of grade rings shall be used to adjust the level of the manhole frame (12 inches maximum between the top of the tapered manhole section and the bottom of the manhole frame). Manhole steps shall be located on the downstream side of the manhole. Backfill shall be placed uniformly around the outside of the manhole so as to not create differential forces and the possibility of dislodging the manhole sections. Where a manhole is constructed on an existing straight-through sewer, the top portion of the sewer pipe shall not be removed until the manhole has been completed and tested. 1.05 TESTING The Contractor shall conduct an exfiltration test or vacuum test on each manhole constructed. The test shall be conducted by the Contractor in the presence of the Engineer. Exfiltration tests shall consist of plugging incoming and outgoing sewer lines and filling the manhole with water up to the rim. After initial absorption (15 minutes), if the water loss exceeds one inch in depth in five minutes, the manhole shall have failed the test. Each manhole which fails the test shall be carefully inspected to determine the problem and then resealed and retested until the water loss is less than one inch in five minutes. Vacuum tests shall consist of drawing a vacuum on a sealed manhole and measuring the time for the vacuum to drop to a predetermined level. The actual test procedure shall be provided by the manufacturer of the test equipment and approved by the Engineer. Each manhole which fails the test shall be carefully inspected to determine the problem and then resealed and retested until the manhole passes. *** END OF SECTION *** CITY OF PALO ALTO: Precast Concrete Manholes Page 2 of 2