Nova NanoLab/Strata DB FEG SEM in the Nova/Strata DBs Source

advertisement

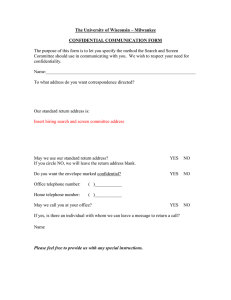

FEG SEM in the Nova/Strata DBs Nova NanoLab/Strata DB FEGSEM Source Column Chengge Jiao Detectors 2 Source: FEG Electron Source Source: thermionic and field emission source W hair pin Work Function LaB6 single crystal <110> Lanthanum hexabroide CFE <310> W SE <100> with ZrO 4.5 2.4 4.5 Lowered From 4.5 to 2.8 106 107 109 109 1 1 0.2 to 0.4 0.5 to 0.7 1.3 x 10-4 2 x 10 -7 5 x 10-11 5 x 10-9 40 - 100 500 > 5000 > 5000 Electrons need to have more energy than the work function (WF) to leave the emitter. Their energy depends on the temperature, so heating can be used to cause emission (thermionic emitter like W or LaB6). (eV) Brightness (A/cm2/Sr) Energy Spread (eV) Operating Pressure (mbar) Life time (hours) 3 FEI Confidential Copyright © 2006 FEI Confidential Copyright © 2006 The WF depends on the material, so choosing a material with a low WF helps emission (LaB6 or ZrO layer on FEG emitter). It also depends on the crystal orientation (FEG). The Schottky effect is that the WF becomes lower when a strong electric field is applied on the emitting surface (used in the FEG). 4 FEI Confidential Copyright © 2006 1 Source: Schottky emitter Source: FEG filament temperature As soon as the temperature is high enough, the Zirconium Oxide will melt and flow to the tips’s end. WF: Tungsten A Schottky emitter is a FEG with a lower working function working function by ZrO. A temperature is needed to melt the ZrO. The Shottky emitter starts with the emission as soon as the ZrO has reached the tip. Temperature: 1800K WF: lowered with ZrO High Temperature: High emission Warm field mitter. mitter. Tip diameter is 500nm The working function is lowered now, so the tip will start emitting when there is an extraction field. Too high temperature: ZrO evaporates before it reaches the tip. The emission increases when increasing the operating temperature of the tip: until approx. 1850K. diffusion 5 ZrO bulb Low Temperature: Low emission FEI Confidential Copyright © 2006 6 ZrO Flow positive extraction field for field emission FEI Confidential Copyright © 2006 The column: Vacuum Source: Schottky Emitter The operating vacuum for the Schottky emitter must be better then 2 x 10-8 mbar; however the lower 10-9 range is recommended. The system vacuum is: Upper IGP (2) vacuum: < 2x10-9 mbar Lower IGP (1) vacuum: < 2x10-7 mbar T M = Tip module W = Welded tungsten Tip Fil = Tungsten wire filament T = Sharpened Tip Zr = Zirconium reservoir Zr M W Fil 2 IGP’s cascaded: the lower IGP backs up the upper IGP Vacuum is achieved by bake-out Items baked out: Emission Chamber outside, Tip module inside, Upper IGP 1 torr = 1.33 mbar = 133 Pa 7 FEI Confidential Copyright © 2006 8 FEI Confidential Copyright © 2006 2 Schottky Gun Design Where are the 6 lens ? C1 F: Filament current input (2.1 to 2.4 Ampere) S: Suppressor (-500V FEG or 950 V Sirion FEG) E: Extractor (+ 4 to 6 kV) Gun alignment C2 F S Deceleration UHR/Intermediate E C1: Electrostatic condenser lens Scan coil assembly C1 UHR/Immersion HR/normal FEI Confidential Copyright © 2006 9 The upper three lens: Condenser Optics - Spot Size Dgun source FEI Confidential Copyright © 2006 10 Column: the upper part of 3 lens Dgun C1 Coulomb Tube v1 C1 Gun Alignment Coils C2 v2 b1 Objective Aperture v2 C2 crossover b2 Dxover Spot 7 A high current 11 b2 Scan Coils Dxover M = (b1/v1)·(b2/v2) Dxover = Dgun·M FEI Confidential Copyright © 2006 Objective Lens Spot 1 A low current 12 FEI Confidential Copyright © 2006 3 Crossover position in aligned column Modes of operation X-over Dec. Lens Mode I: Searching Mode/HR Mode On a perfectly aligned system the disk is cantered on the aperture when the scan is zero, i.e. the middle of the image, except that the whole image is shifted to the right. This is because in the cross-over mode, the SEM scancoils are turned off. The image is generated by the Gun-Shift coils in the top of the column. The shift coils are scanned slower than the HR/AC/DC coils results in the cross-over to the right. 0.3D FLA D Upper scan Lower scan Final lens FEI Confidential Copyright © 2006 13 5 kV Mode II: UHR Mode Excellent imaging at low kV as the sample can be close to the virtual lens which reduces Cc. Use of highly efficient within-the lens detector with SE, BSE and Mix capability. Full resolution at tilted condition. Easy and fast switching between modes. Mode III: EDX Mode A proper lens current remnance setting for EDX mode use FEI Confidential Copyright © 2006 14 Atomic number on the interaction volume Beam energy on the interaction volume 1 kV Large field of view for easy navigation. Low magnetic field at the sample. Ideal for magnetically sensitive samples. 30 kV BCN, density 1.805 Zn, density 7.14 W, density 19.30 Monte Carlo electron trajectory simulations of interaction volume of different materials at 5 kV beam energy Monte Carlo electron trajectory simulations of interaction volume in aluminum as a function of beam energy 15 FEI Confidential Copyright © 2006 16 FEI Confidential Copyright © 2006 4 Acceleration voltages, spot sizes, apertures Acc. voltage Use 3-5 kV 5-10 kV High resolution imaging, e-beam deposition General imaging, light element X-ray mapping 10-30 kV Heavy element X-ray mapping Spot size Use 1&2 1–3 4–7 Very high resolution (mag > 50k X) Standard imaging X-ray analysis, EBSD, e-beam deposition HR and UHR mode NOTE – the NOVA NanoLab / Strata GUI does not display spot sizes but the approximate beam current at the respective spot. 17 Aperture Use 30 µm 30 µm 50 / 100µm High resolution imaging - 5kV, spots 1,2,3 General use X-ray mapping at low kV FEI Confidential Copyright © 2006 FEI Confidential Copyright © 2006 18 Intermediate Lens/Virtual objective aperture Lower Three Lenses HR Mode X-over 5 micron UHR Mode EDX Mode 30 micron Final Lens Aperture Inter mediate lens Intermediate Lens UHR lens Specimen Internal Lens External Lens Intermediate/UHR lens combination: No need to change aperture when switching between HR and UHR modes 19 FEI Confidential Copyright © 2006 20 FEI Confidential Copyright © 2006 5 HR and UHR mode HR and UHR mode UHR mode Immersion lens Search lens OWD 60° pole = 51mm deflectors OWD = 31mm FWD = 5mm OWD = 3mm In UHR mode, the magnetic field does not stay inside the lens and the specimen is in the hearth of the lens. 21 FEI Confidential Copyright © 2006 FEI Confidential Copyright © 2006 22 Why HR mode is not suitable for XEDS analysis EDX Mode If we do XEDS in HR mode The external lens is activated but is much weaker than in UHR mode. BSEs can escape and strike EDX detector, causing too high a count rate and dead time BSE can bounce off final lens and re-enter the specimencreating stray X-rays Intermediate Lens Intermediate Lens TLD TLD and SED can be used. BSE Can be useful for looking at magnetic samples. EDX SED Weak External Lens Specimen 23 FEI Confidential Copyright © 2006 Specimen 24 FEI Confidential Copyright © 2006 6 Resolution / Probe current EDX Mode Spot Size 1kV W D=2mm nm pA 2.5 1.4 2.5 7.4 2.7 30 2.8 120 3.1 460 3.6 1900 7200 Intermediate Lens 1 2 3 4 5 6 7 BSEs are trapped by the immersion lens either in UHR or EDX mode. EDX BSEs 5kV WD=4mm nm pA 2.3 5 2.3 25 2.4 98 2.5 400 3.7 1600 4.7 6300 24000 15kV W D=5mm nm pA 1.5 10 1.5 36 2.2 140 2.5 580 3.5 2200 5 8900 34000 30kV W D=6.2mm nm pA 1.5 21 1.5 44 1.7 150 1.8 630 2 2400 3.8 9500 37000 NOTE – the NOVA NanoLab / Strata GUI does not display spot sizes but the approximate beam current at the respective spot. Objective Lens Specimen Low Voltage Limitations FEI Confidential Copyright © 2006 26 WD/kV limitations in Mode II 6 0A Longer electron-electron interaction times and smaller electronelectron distances lead to higher statistical aberrations at low kV re co N m ot m Po m en ss m de ib en d l e de ar d e a f o Im r H U po HR s UH i gh s R i cu b cu Re l rr e A s rr en r en ol t a ut t > ea io b 10 n ou t A 1 FEI Confidential Copyright © 2006 5 WD, mm Chromatic aberration is more dominant at low voltages. 4 3 2 1 Re co 25 1 27 FEI Confidential Copyright © 2006 28 4 9 16 HT, kV 25 36 FEI Confidential Copyright © 2006 7 Detector SFEG: HR mode SED detection Normal Secondary Electron Detection Why a through the lens detector? light pipe2 Through the Lens Detector (TLD) light pipe1 10 kV The secondary electrons are trapped in the strong magnetic field between lens and specimen in the UHR mode. So, a detector which can detect secondary electrons from the optical axis is need. SE electrons are detected by a positive bias (20~25 Volt) and split from the optical axis by a special device: a deflector. 10 kV visible light Bias TLD (-10V) Bias SED (+250V) SE electrons FEI Confidential Copyright © 2006 29 FEI Confidential Copyright © 2006 30 TLD Configuration Detector SFEG: UHR detection SE mode TLD secondary electron detection Within-the-lens detector is part of the final lens.Bias voltage between -250V and +250V . Grid is -25V. SE: positive suction tube voltage of 20 or 25 Volt. BS: negative suction tube voltage. Down hole: very positive suction tube voltage (>150Volt). Charge reduction: suction tube voltage zero. Visible light SE electrons -V 2V -V V -2V Illumination screen 10 kV V Illumination screen 10 kV Bias TLD (+20 or 25V) Bias SED (-25V) 31 FEI Confidential Copyright © 2006 32 FEI Confidential Copyright © 2006 8 EBID - Electron beam induced deposition Detector SFEG: UHR detection BSE mode TLD back-scatter detection -V V -2V 2V Electron beam 10 kV Available metals BSE SE 33 Comparison of electron and ion beam deposition 10 kV V -V Bias TLD (-250V) Patterning capabilities using the electron beam in conjunction with the gas injector system (GIS) Bias SED (-25V) FEI Confidential Copyright © 2006 EBID - Electron beam induced deposition Examples of electron beam deposited patterns 34 Ion beam Pt, W, silicon oxide Deposition rate Low High Milling prior to deposition No Yes Ga inclusion No Yes Purity of deposit Process dependent High Min feature at HAR / LAR 28 nm / 12 nm 40 nm / 20 nm FEI Confidential Copyright © 2006 Alignment order Final Lens aperture strip manual mechanical position alignment 81 Crossover holey point calibration 10 Source Tilt and Shift 44 UHR Lens Alignment 42 UHR Stigmator Alignment 43 UHR Image Shift Correction 45 HR image Shift Correction 35 FEI Confidential Copyright © 2006 36 FEI Confidential Copyright © 2006 9 Final lens aperture • Reduces coulomb interactions • Electronic Beam Centering • Silicon wafer design/Molybdenum coated • 30 micron gives good all round operation FEI Confidential Copyright © 2006 37 Alignment function overview Procedure Function 5 – Emitter Startup Enables electron gun switching on/off and to change gun emission mode. In case of emergency shut down it makes also possible to start IGP. 10 - Source Tilt and Shift Corrects source tilt and shift for the whole range of the accelerating voltages and spotsizes. 44 - UHR Lens Alignment Eliminates image shift when focusing in UHR (immersion) mode for the whole range of the accelerating voltages and working distances. 42 - UHR Stigmator Alignment Alignment Eliminates image shift during normal stigmator correction in UHR (immersion) mode for the whole range of the accelerating voltages and working distances. 43 - UHR Image Shift Correction Eliminates image shift during HV change in UHR (immersion) mode for the whole range of the accelerating voltages and working distances. 45 - HR image Shift Correction Eliminates image shift during HV change in HR mode for the whole range of the accelerating voltages. 13 - Stigmator alignment Alignment Eliminates image shift during normal stigmator correction in both HR and UHR modes. 17 - Stage Rotation Center Corrects the center of rotation at any point on the specimen by computer correction of the X, Y offset from the stage mechanical center. 38 FEI Confidential Copyright © 2006 Aligned system When all alignments are done properly, the image will stay in focus, its rotation will be corrected, and it will not show a substantial image displacement when you change kV and, or beam current. Further more the Ion beam and Electron beam should be in coincidence and report the same sample location accurate for milling / imaging purposes. 39 FEI Confidential Copyright © 2006 THE END 40 FEI Confidential Copyright © 2006 10