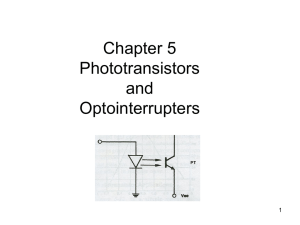

Application Notes: Photodiodes, Phototransistors, and Infrared

advertisement