CITY MULTI® CaTaLog - Mitsubishi Electric

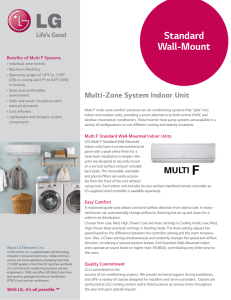

advertisement