Five Best Practices for Quality RF ATE Measurements

advertisement

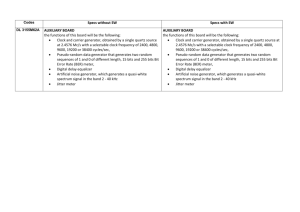

Five Best Practices for Quality RF ATE Measurements: Achieving Quality RF Results through Variation and Repetition INTRODUCTION In order to make quality measurements, repeatability is nonnegotiable. Studying variation in reproduced measurements determines the character of a desired RF ATE test measurement. Repeatability If you cannot make repeatable measurements, you cannot make good measurements. How do you know that you can make repeatable measurements? Duh. Make the same measurement over and over again and examine the variation. Connector torque is an important consideration for repeatable RF measurements. Know your connectors and know their torque requirements, and, use the proper tools. They are not hydraulic fittings that must withstand 3000 psi! And, use the proper tools properly. Brass connectors often have lower torque specs than their stainless steel counterparts. And, use proper tools properly with the proper torque. Test your measurements with varying amount of settling time or averaging. You should more or less know the expected level you are about to measure. Higher signals do not suffer so much from signal to noise issues as do lower amplitude signals. With lower level signals, you can expect a lower signal to noise ratio. Because noise is generally randomly distributed, a typical solution to battling low level signals is to average your readings over a longer measurement period. Or, take many readings and average them together. Someone says “I can measure the RF power in one millisecond with repeatability!” Yes, but how accurate is that measurement? It may be possible to consistently get the same measurement over and over again and still not get an accurate measurement with time varying signals, or if your instrument is not settled from a previous configuration change. You need to know your signal characteristics before you can measure it accurately. Measure it several different ways if possible. For example, use a spectrum analyzer in addition to the power meter. "It may be possible to consistently get the same measurement over and over again and still not get an accurate measurement with time varying signals." Let’s go with a typical measurement scenario: You want to measure the signal strength output from a cable attached to an RF signal generator. You might start by averaging a large number of readings (maybe something ridiculous like 100) and recording the results. Try this several times to give you confidence in your measurement value. gsystems.com 2 Then, try cutting the number of samples in half. Record and cut in half again until you see a significant change. When you see a significant change, you can fall back to the previous higher number of samples in order to average out the noise. Higher amplitude signals may only need one (1) to ten (10) samples to yield satisfactory stability in measurements. You can keep cutting the number of samples in half and converge on an appropriate number of samples that gives you repeatability that you desire. If you are using triggered or windowed measurements, you may want to vary the trigger delay around to make sure you are measuring when you think you are. A familiarity with the nature of the signal in question will help you with this exercise. When measuring time-varying signals, using a spectrum analyzer in zero span mode can give you a nice picture of how that signal is varying with time. Using a spectrum analyzer in zero span mode is like using an oscilloscope, but to measure RF waveform power. That can be tuned. High slew rate RF signal measurement are limited by the resolution bandwidth (RBW) of the analyzer. For example, if your spectrum has a maximum RBW of 10 MHz, you are not going to be able to measure RF signals that change with nanosecond rise times. The effect is as if a low pass filter is applied to the rise time response. Frequently, the RBW adjustability comes in handy when measuring an RF signal that is concentrated around a single RF frequency or small range of frequencies, because you can adjust the RBW to help filter out noise that you don’t care about. If given the chance, make relative RF measurements instead of absolute RF measurements. Accuracy vs. Relative Measurements If given the chance, make relative RF measurements instead of absolute RF measurements. Sometimes you can avoid characterizing your test setup completely if you make relative measurements. A common example is making gain measurements of an RF amplifier. Since there is no frequency translation in an amplifier, you can first connect the measurement system without the amplifier in place. Carefully record the frequency response of your system ?sans? amplifier. This will be your reference response. Then, insert the amplifier into the test system and re-measure the frequency response. Subtract the reference response from the response with the amplifier to obtain the frequency response of the amplifier alone. You have just made a relative measurement. This relative measurement strategy is sometimes complicated by nonmatching UUT connectors and might require a new RF adapter to be able to connect the UUT input and output connectors together. If you are extremely lucky, you can connect the cables directly together without an extra RF adapter. If not, seek to balance out the number of gsystems.com 3 adapters used between the reference measurement and the second measurement. If you can use the same number of adapters in both measurements, and they have about the same insertion loss and response vs. frequency, then their contributions to each measurement will cancel out. Pathloss Sometimes you need to make absolute measurements of an RF signal instead of relative measurements. In this case, it is important to know the loss of any RF components between the signal of interest and your measuring instrument. These might include any number of RF relays, interconnecting cables, attenuators, and adapters. These pathloss contributions must be carefully characterized because they become part of every subsequent measurement in a one-to-one proportion. It is important to get these right! As an example, suppose I wanted to apply exactly -10 dBm to the input of my RF widget during testing. If only a single frequency was required, I could simply replace the widget with a power meter and adjust the power output of my signal generator to as close to -10 dBm as possible. Then I would disconnect the power meter and connect my widget for testing. I’ll arbitrarily call this Pathloss Technique #1. What if I needed to apply -10 dBm over a range of frequencies? Too many to setup and calibrate manually. The preferred method would be to setup the signal generator and power meter under computer control and perform the power adjustment at each frequency, recording the value needed on the signal generator at each frequency. For each frequency, I would tweak the output power of the signal generator until my target power value was met. I could then apply these amplitude values each time I changed frequency and I would have -10 dBm for every frequency. Assuming your RF signal generator is very repeatable, you can recall these settings each time you need to change frequency. You could even expand this technique for different power levels if you know beforehand what the required power levels will be. I’ll call this Pathloss Technique #1 Extended. You might end up with something like Table 1. gsystems.com 4 From Table 1, you can see that at 1 GHz, there is about 1.7 dB loss (8.31 – (-10)) thru the test system to the UUT. The loss increases to around 5.01 dB (-4.99 – (-10)) at 4 GHz. There is probably a six foot cable between the RF signal generator and the UUT judging by the losses. An alternate way of slaying this problem is to setup your signal generator at each frequency to a known displayed power level. Then, measure the resulting actual power with your power meter. For example, you would set the signal generator to 0 dBm as display on its front panel at the first frequency. Then you would read the power meter, proceeding for each frequency in turn. You might expand this technique for different power levels. This is a job for computers. Under computer control you could build up a matrix of power vs. frequency similar to that below in Table 2 shown graphically in Figure 1. I’ll call this Pathloss Technique #2 Extended. Pathloss Technique #2 appears similar to the first technique, but is a little different. In Pathloss Technique #1, the signal generator output is adjusted incrementally (either manually or under computer control) until your desired target power is achieved. When the target is spot on, gsystems.com 5 you record the displayed amplitude from the signal generator and use this value any time you want the same target power. The results are a simple lookup table. As an aside, Pathloss Technique #1 may require a bit of time depending on how close you wish to get to your target power. If your tolerance is small, sometimes it takes several iterations to find the target. Sometimes, you just cannot quite reach the target power, oscillating back and forth around the intended target. Your algorithm must be smart enough to know when to give up when building the lookup table. In the second technique (example results in Table 2), you set the signal generator display to fixed levels and measure the resultant power at your UUT. To make this really accurate, you would want to pre-measure at as many frequency points and at as many power points as possible. However, this takes a lot of time. You can compromise by taking fewer frequency and power points. Then, if you ever want a power in between any two frequency points or power points, you can interpolate between them to get the power level to send to your RF signal generator at that frequency and target power output. Typically, when interpolating, you can assume a linear curve for frequency. However, you must assume a logarithmic curve for power expressed in dBm. Then you record the difference between the displayed value and the calculated value, add that to the displayed value, and write the new displayed value to the signal generator. For example, in Table 2, if you wanted -13 dBm at 1.0 GHz, you notice that at 0.00 displayed value, the level is actually -7.50. At -10.00 displayed value, the level is actually -17.59 dBm. Convert to milliwatts, use straight line interpolation, and convert back to logarithmic power. For 13 dBm actual power output, you should program the signal generator to a level of -5.48 dBm. Now in this second technique, there are some assumptions you must work with. You must trust the output leveling attenuator on your signal generator to be fairly linear, accurate, and having sufficient resolution. This is often the case with modern signal generators. Attenuation in modern RF signal generators can be achieved either by a variable attenuator or by varying the signal level before the output attenuator, such as by adjusting the DAQ gain. It turns out DAQ gain can be much more accurate than a variable attenuator. But if the accuracy of the variable attenuator built into the output of your RF signal generator is adequate, this simplifies things. gsystems.com 6 The advantage of Pathloss Technique #2 is the time required to build up the matrix. You don’t need to iterate around to find your target value. You simply configure the displayed value, sample the power with adequate averaging, and go to the next point. The disadvantage of Technique #2 is you must build a proper interpolation algorithm to find those points in between. Some RF signal generators have the ability to store the delta between the displayed value and the actual value. Then, they can be configured to display the actual value. Looking at the first entry in Table 2, we see that the displayed value is 0 dBm while the actual value at the UUT is 7.50 dBm. Writing -7.50 to the appropriate instrument register and turning on the offset results in the displayed value of -7.50 dBm (with an actual value at the UUT of -7.50 dBm)! This is pretty useful to keep power levels straight when testing. Warning! This might confound bystanders that are not familiar with this feature of some signal generators. So far, I have only addressed the pathloss for devices that generate RF signals. The preceding examples are applicable whether using an RF signal generator or measuring the signal generated by your UUT. What about measuring pathloss for measuring instruments such as a power meter or vector signal analyzer? The short answer is that you need to establish an accurate reference level at the point of measurement and take the measurement with your instrument. Doing the math will give you the pathloss between your reference point and the measuring instrument. Let me describe the process in more detail. Suppose you want to characterize the loss from the UUT output thru a flexible RF cable, back thru your interface drawer, thru a set of RF relays, then to your RF signal analyzer. After all, you want to know the power at the UUT output, not the power at your signal analyzer. Set up a reference power by, for example, connecting a cable to an RF signal source with a high quality cable and a high quality attenuator (6 to 10 dB) at the end. Connect this directly to your power meter. Set the signal source to all the various frequencies you might need and take careful readings on the power meter. These numbers become your references. Then, disconnect the power meter and connect the reference point to the cable that will be connected to your UUT output. Replay all the frequencies you previously recorded while making level measurements with you signal analyzer. Subtract the measurements on your signal analyzer from the reference powers. The delta values are the pathloss between the UUT output cable and the signal analyzer. gsystems.com 7 The process of calibrating measurement pathlosses takes twice as long as stimulus pathlosses because you must make twice as many measurements. There are also more chances for mistakes. Keep any cabling as stationary as practical to prevent changes in reference power during the two runs. Try to minimize any additions or subtractions of adapters between the reference run and the final run. Make certain the readings are realistic and repeatable. Isolation or Crosstalk Good isolation inside your RF ATE is important for quality measurements. When dealing with sensitive measurements like phase noise, it doesn’t take much crosstalk to ruin your reading. One of the first overlooked items when dealing with crosstalk is your RF cables. Quality RF cables have their shielding effectiveness specified on their datasheets. If it is not specified on the data sheet, and you are dealing with sensitive measurements, you may want to pass on that brand. If you want good shielding to improve your isolation, you may want to go with a foil wrapped and braided or double-shielded outer braid on your coax. The ultimate in shielding is obtained with semi-rigid coaxial cable. At the expense of flexibility. Semi-rigid is a good choice inside the ATE where cables should be fastened down anyways. Use flexible cables only where necessary if you are looking for the best isolation with the least amount of potential crosstalk. "Good isolation inside your RF ATE is important for quality measurements." Another widely used component that influences isolation is the RF relay (or RF switch). You should choose your relays appropriately based on their isolation between open terminals at your frequency of interest. Shown in Figure 2 below is a simple RF multiplexer built by cabling together three (3) single-throw double-pole (SPDT) RF relays. These are very useful and sometimes can be built more cheaply than buying a dedicated 4:1 or 6:1 relay. Especially if you have orphaned relays leftover in your ATE PXI chassis. Keep the cables identical with identical lengths and since the relays have very symmetrical loss from each pole to the common, you will end up with very consistent pathloss thru this 4:1 MUX. One thing to watch out for is crosstalk. You will notice that in Figure 2, channel 2 is connected thru the first level and goes to the last common relay before the measurement instrument. The implication is that the last relay sets the isolation specs for this MUX architecture. If you have the opportunity, you can connect a signal with a low level to channel 2. Thus when you want to look at channel 0, any crosstalk is that much lower. But flexibility in picking channels isn’t always available. Improvements can be made if the first level relays are preceded by single-pole single-throw RF relays (SPST) as shown if Figure 3. This gsystems.com 8 effectively doubles the isolation spec of the RF switches with all else being equal. Any signal present at channel 2 input is reduced by the isolation of two (2) relays before reaching the measurement instrument. Another consideration when using RF switches is lifetime. There is a mechanical lifetime specified for the switches that should exceed your requirements. There are only so many times the little metallic contacts can bang together and keep their sanity. There is also an electrical lifetime associated with the switches if you switch live signals thru the relays. The electrical lifetime is always less than the mechanical lifetime. Most of the wear due to switching live signals occurs during the make or break process. You can extend the lifetime of the relays by using cold switching. That is, turning off the signal, switching the gsystems.com 9 signal, and turning the signal back on. This strategy only works if the mechanism turning the RF signal on and off and back on is an electronic switch and not another poor mechanical relay. RF relays exhibit a slight improvement in insertion loss once they are broken in. You might measure 0.76 dB loss when the switch is brand new and later measure 0.61 dB insertion loss after break-in. It’s good to know in case small amount affects your measurement accuracy. Break-in usually takes several hundred switch cycles. Everywhere there is an RF adapter, there is a chance for signal leakage. Minimize the use of adapters. Use high quality adapters. Stick with the same connectors throughout your ATE to reduce the need for adapters. Return Loss / Reflections High Standing Wave Ratio (SWR), caused by high Reflectivity (Γ) is high up on the RF ATE designer’s list of enemies. Reflections are caused by mismatches from the primary impedance (Z0=50 ohms) of various system components such as adapters, attenuators, splitters, cables, and connectors. One of the more popular impedances for RF components is 50 ohms with 75 ohms a distant second. Sometimes, the mismatch comes when you connect your ATE to the UUT. Sometimes you don’t see this mismatch when calibrating your ATE. It only becomes visible when the UUT data is examined. Frequently, it is worth it to invest in high quality components in order to minimize the effects of reflections. There is a common uncertainty in measurement when making RF measurements called Mismatch Uncertainty. Because many measurements are made without knowing phase information represented in your signal, there will be uncertainty when the signals are combined together. Do they add constructively or do they cancel or is the signal somewhere in between? Mismatch Uncertainty is given by the following equation. Let me illustrate the problem of reflections using a recent project I was working on. In the process of measuring the pathloss of a test setup so that I could generate accurate power levels, I came across the following results seen in Figure 1. I was measuring the insertion loss between an RF signal generator and the connector that would connect gsystems.com 10 to the UUT when testing. I first measured the power at the output of the RF signal generator using a GPIB controlled RF power meter at over one hundred (138) frequencies. This became my reference power vs. frequency. Then, I connected the cable to the RF signal generator and connected the power meter to the UUT end of the cable. Again, I measured at the same frequencies, subtracted the reference power, and plotted the pathloss vs. frequency in Figure 4. All these operations were controlled by a software program written in LabVIEW 2014™. Performing these types of measurements manually would take too much time and be error prone from hand operations. The data taken for these graphs took about 5 minutes. I intentionally had the software average the power meter readings heavily in order to measure very accurately for both the reference and last pass. These pathloss calculations would be used for all subsequent UUT testing for the duration of this project. I wanted them to be accurate, not fast. Experiments showed a very repeatable set of numbers from the LabVIEW application. Examining Figure 4 shows that there is significant ripple in the frequency response between the RF Generator output and the UUT connector. There is an overall downward slope which we would expect to see (Figure 5). But, this downward slope is dwarfed by the ripple which eyeballs out to roughly 0.6 dB peak-peak. This ripple is caused by reflections in the cabling between the RF generator and the UUT end of the cable. I was using a couple of cables connected by an adapter. I think the cables were of the RG-142 variety with standard gsystems.com 11 male SMA connectors. Overall, their combined length was about 5 feet plus or minus a couple of inches. (Actually, the customer I was working with found these cables laying around and decided to use them in the test setup. I was stuck with them.) If you take the frequency span by looking at the first peak and last peak (or first and last valley) you can see the ripples span about 1.325 GHz. If you divide that span by the number of peaks (or valleys) which number 20, you will notice that the average distance between peaks is about 66.25 MHz. If you look up the specs for the RG-142 cable that we were using, you find out the velocity factor is 70% of the speed of light. If you take the speed of light (about 3x108 meters per second), multiply by the velocity factor (0.70) and divide by 66.25 MHz, this works out to a total length of 3.16 meters. Now this is the round trip length for the reflections so we divide 3.16 meters by 2 and convert meters to feet and we get 5.2 feet. Eureka! That is the combined length of my RF cable between the RF signal generator and the UUT connector. Rats! There are significant reflections at the UUT connector that bounces back toward the RF signal generator, hits it and then combines with the forward RF wave to produce these terrible ripples. One well known technique to reduce these ripples comes at the expense of increased insertion loss. Since the input power of my UUT gsystems.com 12 was quite a bit lower than the output of the RF signal generator, I knew that increased insertion loss would not be a problem. I added a 6dB attenuator to the end of the cable where the UUT would connect. Now, when the signal traveling from the RF signal generator goes thru the attenuator, hits the UUT, and reflects back, it would be reduced by twice the attenuator or 12 dB. If using this technique, you should use high quality attenuators to minimize their contribution to reflections. See Figure 6. Another aside: The problem really manifests itself because the RF signal generators are not known for having a really good output match to 50 ohms. Consider if the forward wave that bounces off of the UUT and returns to the signal generator is completely absorbed by a good match. There is no secondary forward wave and consequently no ripple because of reflections! Don’t be deceived by the scale of Figure 6. The straight line fit went from about 0.55 dB per GHz to about 0.6 dB per GHz of slope. An insignificant change is not entirely unexpected. Pathloss has increased by about 6 dB from the attenuator. However, the ripple has decreased dramatically to around 0.25 dB peak-peak average across the band. Since the accuracy of the power delivered to the UUT was specified to be ±0.25 dBm, this test setup was good to go. Greater improvements in ripple could have been had if larger attenuators had been available. Also, eliminating the extension cable, only using a single cable is always an improvement in impedance mismatches. Using high quality connectors and high quality cables is important in RF testing. Minimizing reflections results in quality RF measurements. gsystems.com 13 TO LEARN MORE ABOUT HOW G SYSTEMS CAN HELP DESIGN YOUR RF TEST AND MEASUREMENT SYSTEMS, VISIT: http://www.gsystems.com ABOUT G SYSTEMS Based near Dallas, Texas, G Systems works with engineers and program managers in the aerospace, defense, and energy industries to create reliable test and measurement solutions. With decades of experience designing and building test systems for these highly regulated industries, G Systems overcomes complex electrical, mechanical, and RF test system challenges by identifying optimal COTS test technology, tailoring platforms, and leveraging proven expertise to achieve each customer’s technical, time, and budget specifications. gsystems.com 14