B-RISK user guide and technical manual

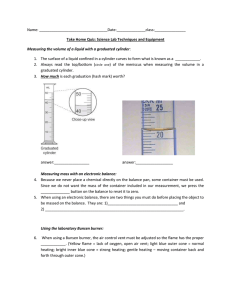

advertisement