nanoindentation of a zinc metal soap mixture for use

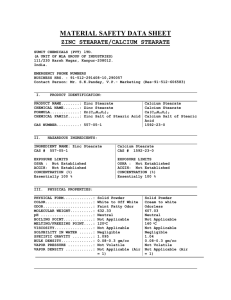

advertisement