The Handbook

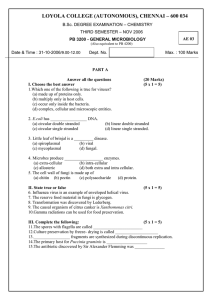

advertisement