CCC ONLY USES HIGH QUALITY ANTICONDENSATION COATING THAT WORKS! WE

SPENT TIME RESEARCHING, TESTING AND

GETTING FEEDBACKS.

Condensation (sweating) can cause serious, even hazardous conditions to both the

surface and surrounding areas where it occurs. Condensation can result in costly

repairs; dripping moisture can cause hazardous conditions in hallways, floors,

stairways and office areas. Contamination of foodstuffs, such as meat, poultry and

dairy products can also be very costly.

The answer to these and many other problems where condensation occurs is

AQUABAN.

AQUABAN is a permanent, water based coating which when applied to a

thickness of 1/32", will prevent condensation by absorption and desorption. This

action widely disperses water vapour and releases it back into the atmosphere

before dripping occurs. Thus the coated surface remains dry to touch.

WHY US?

AQUABAN is fire resistant

ASTME E84 flame spread = 0 and smoke

developed = 10

AQUABAN is non-toxic

AQUABAN has exterior durability.

AQUABAN is available factory tinted to match selected colours.

AQUABAN is cost effective. With the exception of raw wood and mild

steel, AQUABAN REQUIRES NO PRIMER, eliminating the need and

subsequent cost of an additional application. Pipes, including tees

and elbows, air conditioning ducts, especially spiral bound, concrete

walls and ceilings can easily be drip proofed with AQUABAN.

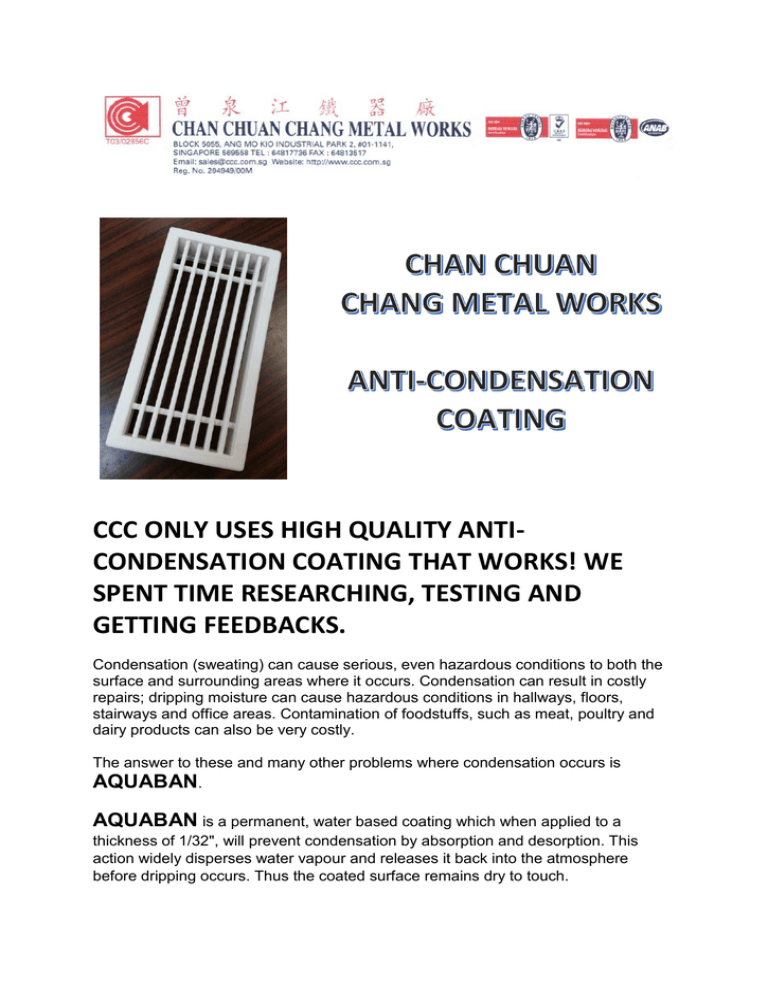

The standard procedure for our Anti-Condensation treatment is 2 layers of

coating to your grilles and diffusers. However, if you requires specifications

with more coating in order to work better, do not hesitate to contact us to

discuss more on your requirements.

It will be good to have anti-condensation treatment for your grilles and

diffusers if that area have changes in temperature.

We offers one of the most affordable anti-condensation treatment you can

find locally in Singapore.

We do not carry warranty for all these anti-condensation coatings, but

please feel free to get back to us for any after services and we will assist you

in whatever ways we could.

Please be careful when installing finished products as these coating are

prone to scratches easily.

Technical Data Sheet

WB-AC/AC-801 PRO-AQUABAN

Anti-Condensation Coatings

03012011 GB

PRO-AQUABAN is a permanent, water based coating, applied to a thickness of 1.1mm, prevents

condensation by absorption and desorption. This action widely disperses water vapor and releases it

back into the atmosphere before dripping occurs. Thus the coated surface remains dry to touch.

PRO-AQUABAN is

• fire resistant

• non-toxic

• permanent

• exterior durability

• apply by brush, roller or spray

Features: No primer required. Excellent adhesion to galvanized steel, mild steel, bonderite steel, PVC,

Masonite, concrete and wood. Good adhesion to aluminum and polyethylene. PRO-AQUABAN sticks to

polypropylene but does not pass adhesion test.

Chemical and solvent resistance: PRO-AQUABAN is resistant to mild acids, alkalis, detergents,

mineral spirits, acetone, esters, and ammonium nitrate. PRO-AQUABAN is resistant to the alkali in

concrete and other masonry products. PRO-AQUABAN can be used on concrete without primer and can

be used as a block filler. When using on new plaster, allow the plaster to cure for 180 days before

applying.

PRO-AQUABAN will soften and swell in aromatic solvents i.e. toluene, xylene and unleaded gasoline.

Fire retardant: ASTM E48, Flame spread = 0

Smoke developed classification = 10

Surface preparation: All surfaces should be clean, free of dust, grease and wax. Heavily rusted

surfaces should be wire brushed and/or sanded. Molded and mildewed surfaces should be washed with

a mildew remover and allowed to dry before applying.

Coverage: Apply PRO-AQUABAN at a thickness of 1.1 mm for most applications. The coverage is 4.5

square metres per 3.785 litres tins.

Drying time: The rate of drying is dependent upon thickness, temperature and humidity. In general, one

coat having a thickness of 0.5 mm will dry in two to four hours at an average temperature of 25° Celsius.

Do not apply when the surface and/or air temperature is below 10° Celsius. Excess drying timing can be

caused by low temperature, high humidity or poor ventilation.

Application: Apply by brush, roller or spray. If applying by spray, use a large diameter spray tip.

Clean-up: Thin films of PRO-AQUABAN cure at an extremely fast rate. Brushes, rollers and spray tips

should be cleaned immediately with water. If cleaning is delayed, it will be necessary to use an aromatic

solvent such as toluene, xylene or Exxon solvent 150 for clean-up.

Distributed by Chemicals Division of:Prolog Marketing Network Pte Ltd

76 Playfair Road #08-05 LHK2 (S) 367996 Tel: +65-63833822

Email: chemical@prolog.com.sg Website: www.prolog.com.sg/chemicals

WB-AC/AC-801 PRO-AQUABAN

Anti-Condensation Coating

PRO-AQUABAN is a permanent, water based

coating, applied to a thickness of 1.1mm,

prevents condensation by absorption and

desorption. This action widely disperses water

vapor and releases it back into the atmosphere

before dripping occurs. Thus the coated surface

remains dry to touch.

Special Properties

-Non-Toxic

- Fire retardant

- Cost Effective

- Requires no primer

- Excellent adhesion

- Exterior durability

- Chemical & solvent resistant

Uses:

- Air-conditioning ducting & grille

- Concrete walls

- Cold water lines

- Cold intake vents

- Metal roofs

- Metal support beams

- Metal switchgear enclosures

- Other usage where condensation

(sweating) occurs

Health & Safety

PRO-AQUABAN is not classified as hazardous

within the scope of EU labeling guidelines.

However, as with all chemicals, reasonable

precautions should be taken to avoid exposure.

Further guidance is given on the product label

and in the Material Safety Data Sheet (available

on request).

Technical Support

The Chemical Division of the Prolog Group is

committed to excellence in product design and

manufacture. The information provided in this

data sheet is intended to guide professional

contractors and specifiers in the appropriate

use of PRO-AQUABAN to ensure a satisfactory

surface treatment. If any further information is

required, please contact our Sales & Service

Centre.

Condensation (sweating) can cause serious

hazardous conditions to both the surface and

surrounding areas where it occurs.

1 Gallon Pack

(3.785 Litres)

Condensation can result in costly repairs.

Dripping moisture can cause hazardous

conditions in hallways, floors, stairways,

warehouses, office areas, computer rooms,

laboratories, hospitals, libraries, museums,

kitchens and etc.

Contamination of foodstuff such as meat,

poultry and dairy products and important

documents and articles can also be very costly.

Distributed by Chemicals Division of:Prolog Marketing Network Pte Ltd

76 Playfair Road #08-05 LHK2

Singapore 367996

Tel: +65-6383 3822

Email: chemical@prolog.com.sg

Website: www.prolog.com.sg/chemicals

Data Sheet, January 2011

All rights reserved.

CERTIFICATE OF CONFORMITY

CUSTOMER NAME: CHAN CHUAN CHANG METAL WORKS

DATE:

2014

PRODUCT: WB-AC AC-801 Pro-Aquaban anti-condensation Coating

The product listed above exhibited the following flame spread characteristics

when applied to a non-combustible substance and tested in accordance with

ISO 9705: 1993(E) (BS476: PART 7) (or equivalent) Standard Test Method

for surface burning.

Characteristics of Material:

SAMPLE

Pro-Aquaban

Anticondensation Coating

FLAME SPREAD

CLASSIFICATION

0

SMOKE DEVELOPED

CLASSIFICATION

0

D WONG

Operations, Asia Pacific

Sales & Service Centre, Chemical Division (Asia II)

76 Playfair Road #08-05 LHK2 Singapore 367996 Email: info@prolog.com.sg

Prolog Marketing Network Pte Ltd

OTHER CUSTOMER TESTING REVIEWS & FEEDBACKS

FROM THE ANTI-CONDENSATION COATING WE ARE

USING FOR YOUR GRILLES & DIFFUSERS